Tungsten Alloy Flywheel Counterweights

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 December 2015 17:52

The flywheel is a kind of disk-shaped components with large moment of inertia, which is used in the large machinery parts or devices, and it plays a role as an energy storage. For the three-generations of nuclear power AP1000 main pump motor, since it is an advanced vertical single-stage, integral sealed, high inertia and centrifugal shielding motor in the world, so the electrical, hydraulic and coasting performance is vital for main pump. But the coasting would be operated abnormally if in the absence of power, and the safety of the reactor may not be safeguarded. Setting up the flywheel on the main pump motor can provide a large moment of inertia and improve the coasting time, thus to ensure the safety of reactors.

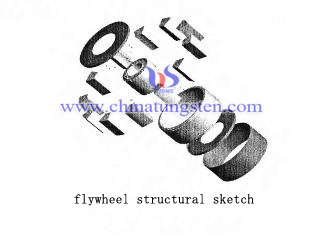

This high inertia flywheel was designed as a heavy metal structure that mosaics with tungsten alloy, it consists of inner hub, the inside of the hub, 12 heavy metal tungsten alloy plugs, the retaining rings, upper and lower cover boards and outer sheath. Because the bias of lower rotating speed causes smaller partial load, but for the high speed of flywheel, it should add counterweights in order to keep its balance. Installing the tungsten alloy block and fixing it in the flywheel hub can reach the aims to add a counterweight to flywheel and to keep the balance when rotating at high speed. This is because of the high density and good wear resistance, high density tungsten alloy, which makes it well balanced for flywheel rotation. When the flywheel is running at high speed it will cause greater friction, then tungsten alloy can solve this problem and not to be wore and teared.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com