Method for Preparing Ultrafine Tungsten Trioxide

- Details

- Category: Tungsten Patents

- Published on Tuesday, 28 October 2014 08:52

- Written by Sherry

- Hits: 2607

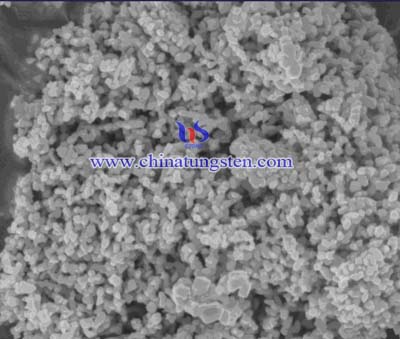

The invention relates to a method for preparing ultrafine tungsten trioxide, which comprises the steps of crystal seed preparation, material proportioning, hydrothermal reaction, separation by filtration, low-temperature roasting and the like. The invention has the advantages of short technical process, mild conditions and no need of complex equipment; the prepared tungsten trioxide has the advantages of high purity and small particle size; the mother solution can be recycled; and the utilization ratio of the sodium tungstate raw material is high.

A process for preparing ultrafine tungsten oxide, characterized by comprising the steps of:

(1) Preparation of seed: the preparation concentration of 10% ~ 52% of the sodium tungstate solution, with an organic acid or inorganic acid to adjust the solution pH to 4.0 - 8.0 range, in the hydrothermal autoclave for 4 to 15 hours, and the resulting precipitate was filtered, evaporation, crystallization, to obtain seed;

(2) Mole ratio of: the concentration of the preparation 10% to 55% solution of sodium tungstate, seed crystals are added to the solution, the seed crystal in the solution quality and the mass ratio of sodium tungstate in I: 2. 5 ~ I: 8. 5 range;

(3) High reaction: sodium tungstate solution with a seed crystal was placed on a stainless steel autoclave at 60 ~ 350 ° C reaction temperature and under strong stirring, stirring hydrothermal reaction, hydrothermal reaction for 4 to 20 hours After stirring was stopped, the autoclave was cooled to room temperature, taken out after one of the solid-liquid mixture;

4) It was isolated by filtration: the step (3) of the liquid mixture in the slurry was separated by filtration to obtain the tungsten trioxide fine cake and a mother liquor;

(5) Low-temperature firing: the fine tungsten trioxide cake was calcined in a baking furnace to obtain the low temperature of the tungsten trioxide fine product;

(6) The mother liquor was evaporated: the mother liquor and the washings were separated by filtration with heating evaporation stage , the concentration of sodium tungstate was prepared from 3% to 20% of the circulating liquor;

(7) Recycling the mother liquor: the loop back to the seed crystal mother liquor preparing step, for the preparation concentration of 5% to 45% of sodium tungstate water.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Method for Preparing Ammonium Tungstate by Treating Waste Tungsten Oxide

- Details

- Category: Tungsten Patents

- Published on Monday, 27 October 2014 13:57

- Written by Sherry

- Hits: 2738

The invention discloses a method for preparing ammonium tungstate by treating waste tungsten oxide, which comprises the following steps of:

Adopting an ammonia water pressure cooking method to dissolve waste tungsten trioxide, blue tungsten oxide, and other tungsten oxide to prepare an ammonium tungstate solution, ammonium paratungstate, ammonium metatungstate and other ammonium tungstate.

Compared the method that caustic soda or soda ash digestion or melting-poaching is adopted to dissolve the tungsten oxide to prepare a sodium tungstate solution, and the method that a solvent extraction or ion exchange process is adopted to prepare the sodium tungstate solution in the prior art, the method has the advantages and characteristics that the procedure process can be simplified, the auxiliary raw materials can be saved, energy saving and emission reduction can be realized, the environmental pollution can be relieved, and the production cost can be reduced.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Method for Producing Tungsten Trioxide Powder for Photocatalyst

- Details

- Category: Tungsten Patents

- Published on Thursday, 23 October 2014 08:57

- Written by Sherry

- Hits: 2730

Disclosed is a method for producing a tungsten trioxide powder for photocatalysts, which is characterized by comprising a sublimation step wherein a tungsten trioxide powder is obtained by subliming a tungsten metal powder or a tungsten compound powder by inductively coupled plasma processing in an oxygen atmosphere, and a heat treatment step wherein the tungsten trioxide powder obtained in the sublimation step is heated at 300-1000 DEG C for 10 minutes to 2 hours in an oxidizing atmosphere. A tungsten trioxide powder obtained by such a method for producing a tungsten trioxide powder for photocatalysts has high photocatalytic activity under visible light.

For the production of the photocatalyst powder, tungsten trioxide, said method comprising: a step of sublimation, in an oxygen atmosphere by using the following types of processing in the distillation of at least ー tungsten powder or the tungsten compound powder to obtain the tungsten trioxide powder : inductively coupled plasma processing, arc discharge processing, laser processing and electron beam processing; and the heat treatment step, in an oxidizing atmosphere at 300 ° C to 1000 ° C in said heat treatment step, the sublimation of the tungsten trioxide powder obtained 10 minutes to 2 hours inches, wherein said powder has a crane crab oxide selected from the monoclinic crystal, rhombic crystal and monoclinic crystal brother of at least two crystal structures, wherein the tungsten trioxide powder has a BET specific surface area of 8. 2m2 / g to 820m2 / g, wherein the tungsten trioxide powder obtained by the image analysis of particle size distribution (D90-D10) / D50 in the 0.3 to 2 range, and wherein said catalyst is a visible light photocatalyst and The wavelength of visible light of 390 to 830nm.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Technology for Producing Tungsten Trioxide by Prilling and Roasting of Tungsten Slag

- Details

- Category: Tungsten Patents

- Published on Friday, 24 October 2014 09:00

- Written by Sherry

- Hits: 2749

The present invention discloses a method for the production of tungsten slag Ball tungsten trioxide roasting process.

Characterized by: includes the following steps:

(1) The tungsten residue after drying join anthracite, mix crushed, then add the lime mud, soda and water , hexadecimal Handicap Ball, made of tungsten mixed slag pellets.

(2) Mixing the ball into the open hearth furnace slag tungsten roasting kiln firing semi-enclosed insulation, too tungsten slag clinker.

(3) Tungsten slag clinker immersion, have a high concentration of ion exchange of sodium tungstate liquor.

(4) Addition of high concentrations of sodium tungstate liquor quality after filtration, reprecipitation, and then the precipitate was rinsed, dehydrated and dried to obtain the product of calcium tungstate.

The invention uses a tungsten residue, anthracite, lime mud and recycling waste as an alternative to traditional baking agent, a wet pyrometallurgical process used is expensive, large consumption of soda ash and burning acid, metal tungsten production cost per ton reduced 6-7 million to make the conversion rate WO3 twenty five percentage points, and successfully resolved the sodium roasting kilns, kiln shutdown ills caked shovel, still in the traditional process, saving on production of wet fire energy consumption by 50 percent.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Preparation Method of Nano Tungsten Trioxide Powder

- Details

- Category: Tungsten Patents

- Published on Wednesday, 22 October 2014 09:02

- Written by Sherry

- Hits: 2788

The invention relates to a preparation method of nano tungsten trioxide powder, and belongs to the field of powder metallurgy technology.

The method comprises the following steps: heating a saturated ammonium tungstate solution till 65-70 DEG C, then adding ammonium chloride, tartaric acid, ethylenediamine tetra-n-propionic acid and diethanol amine respectively in sequence, keeping stirring during the adding process till being dissolved completely and continuously stirring for 1-2h; then adding nitric acid under the condition of keeping stirring to form tungstic acid gel; then putting the gel in a heating furnace for drying at 140-150 DEG C, then warming up till 340-380 DEG C for calcination, and finally ball-milling and smashing to obtain the nano tungsten trioxide powder with the average particle size of 23-28 nm. The method disclosed by the invention is mild and stable for reaction process and easy to control, prepared nano tungsten trioxide is thin and uniform in particles and high in powder purity. Moreover, the process is simple and easy to control, so that the industrial production investment is few, the production technology is simple and convenient, the production cost is low, and industrial large-scale production is convenient to realize.

A process for producing a tungsten trioxide powder of nanometer, which is characterized by comprising the steps of: a saturated ammonium tungstate solution was heated to 65-70 ° C, and then ammonium chloride was added an amount of 8-13g / L, stirring 0.5_lh; tartaric acid were added in sequence and, ethylenediaminetetraacetic acid and diethanolamine were added in an amount ll_14g / L ,23-32g / L and 6-9g / L, was stirred to completely dissolve and continue stirring for 1 - 2h; nitric acid was added and stirring was continued for 320-380ml / L, the formation of tungsten acid gel; the gel is placed in a furnace 140-15 (TC drying, heating rate 1_2 ° C / min, heat l_2h, then 2-3 ° C / min heating to 340_38 (TC insulation 2_3h calcination, ball milling to obtain the final nano tungsten trioxide powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

More Articles...

- Tungsten Oxide Airgel and Its Preparation Method and Application

- A Surface-modified Tungsten Trioxide Europium and Preparation Method Photoelectrode

- Based on Tungsten Oxide Precursor Synthesis Tungstate

- Tungstic Oxide Nano-wire and Method for Preparing Tungstic Oxide Nano-wire Ammonia Sensitive Sensor

sales@chinatungsten.com

sales@chinatungsten.com