Application Scenarios of Tungsten Wire in Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:29

- Written by Zhenghua

- Hits: 2

Tungsten wire has a high melting point, good high temperature stability and compatibility with glass materials, showing a variety of application scenarios in the field of glass heating, covering industrial manufacturing, functional products, precision processing and innovative technologies.

I. Core Heating Elements for Glass Manufacturing and Processing

1. Glass Melting and Forming

(1) Melting Stage: Tungsten wire is used as an electric heating element in the melting furnace in glass production. Its high melting point (about 3422°C) ensures that the raw materials are fully melted and remain in a uniform liquid state, improving production efficiency.

(2) Forming Process: During the tube drawing, blowing or pressing process, tungsten wire provides local heating to keep the glass in a softened state for shaping, while reducing defects caused by thermal stress (such as cracks or deformation).

2. Precision Cutting and Processing

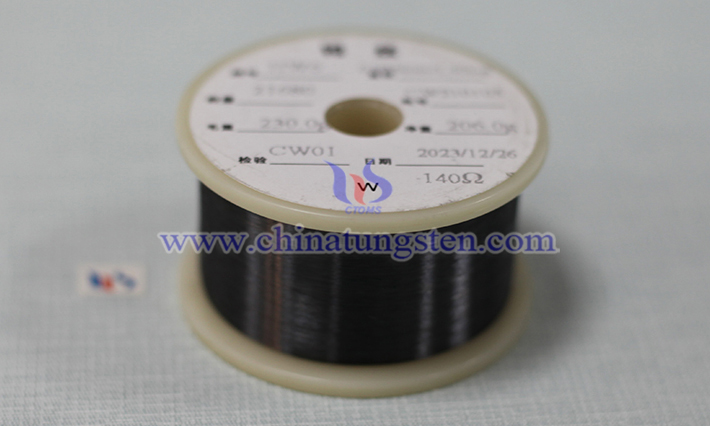

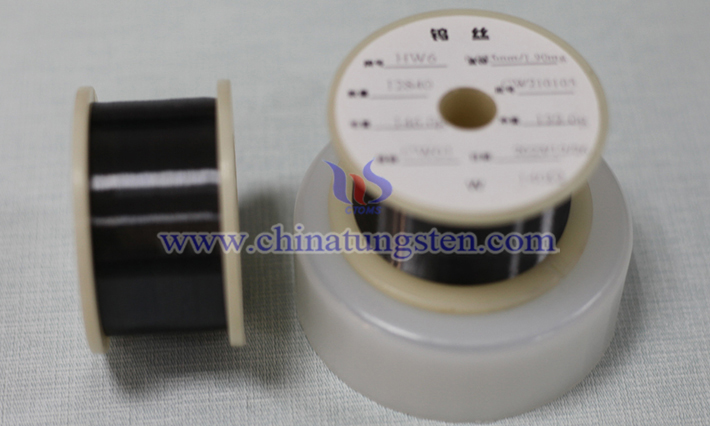

(1) Ultra-Fine Tungsten Wire Cutting: High-precision glass cutting can be achieved through micron-diameter tungsten wire (such as EDM electric spark cutting technology), which is particularly suitable for optical glass, display glass and other fields. Its high tensile strength and high temperature resistance ensure the stability and consistency of the cutting line.

(2) Functional Glass Manufacturing: In laminated glass or smart glass, tungsten wire is embedded and electrically heated to achieve functions such as defrosting, defogging or dimming.

II. Key Technologies for Functional Glass Products

1. Automobile Front Windshield Heating

(1) Defrosting and Defogging: Tungsten wire with a diameter of about 20μm is embedded in the PVB interlayer of the front windshield and connected to the body circuit through the busbar. After power is turned on, heat is generated to quickly eliminate frost, snow or fog, improving driving safety.

(2) Invisible Design: Tungsten wire is almost invisible to the naked eye and does not affect the driver's sight. At the same time, the busbar uses corrosion-resistant tin-plated copper foil to ensure long-term stability.

2. Functionalization of Architectural Glass

(1) Insulation and Heating: Integrate tungsten filament heating technology into glass curtain walls to provide warmth indoors in winter while maintaining insulation performance and improving building energy efficiency.

(2) Intelligent Dimming: Control the heating of tungsten filaments through electric current to achieve dynamic adjustment of glass transmittance to meet privacy protection or energy saving needs.

III. Laboratory and Precision Processing Equipment

1. Thermal Processing of Glassware

(1) High-Precision Molding: In laboratories or small equipment, tungsten filaments are used for cutting, sealing or molding of glassware. Its precise heating capacity meets the production requirements of high-precision glass products (such as test tubes, beakers, etc.).

(2) High-Temperature Testing: Tungsten filaments are used as heating elements for high-temperature performance testing of glass materials to help develop new glass materials (such as high-temperature resistant glass and optical glass).

2. Special Environment Heating

(1) Vacuum or Inert Gas Protection: Since tungsten is easily oxidized at high temperatures, tungsten filament heating equipment is usually used in a vacuum or inert gas (such as argon and nitrogen) environment to extend its service life.

(2) High-Temperature Industrial Applications: In the fields of semiconductors, aerospace, etc., tungsten wire heating technology is used in high-temperature welding, heat treatment and other processes to ensure the stability and safety of the process.

IV. Innovative Applications in the Fields of Art and Architecture

1. Glass Artwork Creation

(1) Light and Shadow Effects: By controlling the tungsten wire layout and current intensity, artists can create unique light and shadow effects to enhance the visual expression of glass artworks (such as sculptures and decorative glass).

(2) Dynamic Interaction: Combined with intelligent control systems, tungsten wire heating technology can realize the dynamic interaction function of glass artworks (such as temperature-sensitive color change).

2. Medical and Scientific Research Equipment

(1) Precision Temperature Control: In the medical field, tungsten wire heated glassware (such as culture dishes and reactors) provides precise temperature control to support experimental and treatment needs.

(2) High Temperature Testing: In scientific research, tungsten wire heating technology is used to simulate extreme high temperature environments and test the thermal stability of materials.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com