About Doped Tungsten Models

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:08

- Hits: 1828

Doped tungsten wire , also commonly known as anti- sag tungsten wire, tungsten, aluminum , tungsten, its main feature is added in the dispersion strengthening elements potassium , forming a " dovetail lap " -shaped interlocking internal grain structure, and thus improved resistance to high temperature creep resistance tungsten .

Doped tungsten complete production line including blue tungsten reduction from APT to the addition of modified elements potassium, aluminum , silicon , and then sintering melt down , rotary forging process , coarse and fine tungsten filament in each step of the process . W31, W61, W91 , and WR15 new high-temperature tungsten filament :

W31

It has as excellent high temperature performance, reeling performance , to meet the energy-saving lamps , fluorescent lamps production use, Weihai polycrystalline material in 5 kg to provide a single , suitable for change pull factory. Grades from Japan , therefore , corresponds to the early use of filament capsule of the user.

W61

Equivalent grades of tungsten in Japan W31 performance and use, provides a single Weihai polycrystalline material in 5 kg , the same change for pulling factory. Grades from China's latest national standards.

W91

With excellent high temperature performance, can be used for high and low voltage halogen lamps , vehicle lights and high performance requirements of high prices on the tube and other fields.

WR15

It's a high -grade , high temperature, high shock tungsten wire, high temperature performance superior W91 grades for high color temperature , energy-efficient ( up C-class energy efficiency standards ) halogen incandescent lamp , is the material of choice for export to EU .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Lanthanum-Doped Tungsten Micro Advantages and Positive Effects

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:05

- Hits: 1696

Lanthanum -doped tungsten micro advantages and positive effects are :

1 Lanthanum -doped tungsten is added to a small amount of tungsten -doped lanthanum , changed the composition of doped tungsten , lanthanum doped tungsten micro cold resistance , heat resistance and other physical characteristics were compared with the conventional tungsten -doped greatly improved, the tests showed that micro- doped lanthanum tungsten cold, heat resistance than conventional doped tungsten are increased by 5 to 7%.

2 , The use of pressure guns lanthanum acid ammonia solution in spray form to be placed in the pot dopant doped tungsten blue spray , can effectively control the addition amount of lanthanum , tungsten is reached improve performance purposes , but also effectively reduce production costs, improve economic efficiency of enterprises .

3 , Increases in the later process of flame oxidation in air annealing step , the processing can effectively eliminate the hardened alloy , the alloy during processing to eliminate the internal accumulation of stress , tensile strength, lower tungsten , the tungsten wire the manufacturing more convenient.

4 , The production of micro- doped lanthanum by the addition of a small amount of tungsten lanthanum , thus changing the composition of the doped tungsten and internal grain size while eliminating the micro by oxidation annealing stress within tungsten doped lanthanum , therefore produced tungsten has a good seismic performance. Tests showed that using this method of production of micro- lanthanum -doped tungsten produced each 10 14V0. 1A0. 7CP bulbs, tungsten specifications for the 1. 0mg/200mm and 1. Ang/200mm, doped with tungsten in the same general seismic tests carried out under the conditions of contrast , the result is a specification of 1.2mg / / 200mm light bulbs, ordinary doped tungsten average number is 673 times the impact resistance , resistance to micro- doped lanthanum tungsten average impact of the number of 1233 ; specifications for a . 0mg/200mm bulbs , ordinary doped tungsten average number of 680 times the impact resistance , while the micro- doped lanthanum tungsten average number of impact-resistant 1209 times.

5, With a simple process, easy to implement and the advantages of low production costs , while the production of micro- lanthanum -doped tungsten has a long life , optical performance, strong seismic performance and a light bulb filament sag after use small amount of features.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Potassium-Doped Tungsten Bulbs Basic Content of Reinforcement Theory

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:56

- Hits: 1838

Potassium foam reinforcement theory of the basic content includes three interconnected parts, which are :

(1) Potassium bubble formation and control. Tungsten oxide is added in trace potassium silicate , aluminum chloride mixed aqueous solution with hydrogen reduced to metal powder , and then compacts , sintering billet . Billet to form a large number of non-uniform distribution of the doping hole φ0.1 ~ 0.4μm . Analysis confirmed that potassium at room temperature to solidify the doped ionic pore walls , and tungsten have a coherent relationship . In the following rotary forging temperature , cold drawing and heat treatment process, the potassium -doped hole is flattened , elongated form along the filament axis orientation distribution of the " K tubes " or " K -line ." The greater the deformation process , the greater the aspect ratio of potassium tube . When annealed tungsten , potassium pipe expansion due to vaporization of potassium ( K boiling point of about 760 ℃), the temperature rose further instability potassium tubular shape , a split of the ovule , a bunch of potassium ordered bubble columns. Potassium tube split ovule instability of the process can be seen as a cylinder instability and approximate equation with perturbation theory and its potassium bubble dispersion model to establish quantitative expression equation, namely the establishment of the aspect ratio of potassium tube and the degree of deformation relationship L / W = (0.75 ~ 1.3) (Do / Dk) 4, ( wherein L, W, Do, Dk namely potassium tube length , width, diameter and tungsten rod original diameter after processing ) , and after dispersion derived The basic parameters of potassium bubble columns : bubble diameter potassium , potassium -containing foam bubble column number and spacing between two adjacent bubbles . Electron microscopic observation and experiment results calculated as consistent with each other . Experimental results and long-term production practice have shown that the necessary amount of potassium- doped hole is to ensure that the basis of potassium bubble dispersion , it depends on the additive potassium -doped tungsten optimum content ; while potassium and potassium bubble pipe split orderly diffusion model can control the degree of deformation and heat treatment through the system to reach . This design -doped Si, Al, K , and a reasonable amount of added processing to develop a reasonable degree of deformation and heat treatment system provides a credible scientific basis .

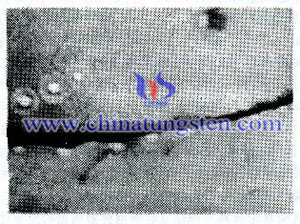

( 2 ) Potassium soak in the process of recrystallization behavior and mechanism of action . Along with the wire axis parallel to the direction of the ordered arrangement of potassium -doped tungsten bulb is caused by recrystallization behavior -specific basis . General material at an appropriate temperature after recovery and recrystallization processes , the formation of equiaxed grains without deformity . However , at high temperature to form doped tungsten filament axis direction along the particular aspect grow large particles , even cross-section of the wire is covered with 1 to 2 grains . It is this special grain boundary growth and finger overlapping grains , the tungsten doped with excellent high-temperature creep resistance , or anti- sag properties of tungsten . Ordered along the filament axis parallel to the direction of the distribution of potassium bubble column, a high temperature high vapor pressure within the bubble to bubble K corresponds to the second phase particles , strong pinning the grain boundary ( see Figure 1 ) , So a aspect suppress recrystallization , improves the recrystallization starting temperature , on the other hand to hinder the grain boundary migration radial filaments , and force it to move the wire axis , thus forming a special aspect of great growing grains ( see Figure 2 ) . The potassium bubble behavior and grain growth model has been a large number of experimental observations and theoretical calculations confirmed, but the details of its recrystallization processes and mechanisms are still not fully unified understanding. The focus of disagreement reply , primary and secondary recrystallization phasing and specific growth or soaring mechanism . Most people think that the first stage of recrystallization primary recrystallization in deformed grains gradually formed simultaneously coarse wire axis parallel to the series as the main feature of potassium bubble , but some people think it is the processing state of the Asian crude fiber bundles crystal ( see sub-structures ) polymerization grew up belonging to a polygon or restoration process . It was also defined as the in-situ re -crystallization process, the formation of the rod or sub-grain ; recrystallization grains elongated second stage is called overgrowth rapid growth or even covered wire cross-section of the main feature. However, this process is defined as the primary or secondary recrystallization still significant differences. Chinese scholar and his research group left Tieyong learn various scholars in the analysis based on the results , after years of systematic experimental and theoretical analysis , published a series of papers presented doped tungsten recovery and recrystallization nucleation mechanisms and recrystallization growth mechanism . The basic conclusion is that : first, the tungsten -doped high-temperature annealing occurs when deformed grains ( or fibers ) change phenomenon , is to resume the process of a special organizational change , grain boundary dissociation , Asia fiber aggregation caused by not once again crystallization behavior ; Second, because potassium bubble column grain boundaries and dislocations movement and its direction is strong pinning effect , resulting in a sub- fiber polymerization process proceeds very slowly and can be extended to temperatures above 2000K ; Third , doping the formation of abnormal grain growth in tungsten seemingly secondary recrystallization soaring organization, but experimental observations and theoretical calculations show that it is not the primary recrystallization occurs in a small number of matrix grain growth resumed , nucleation of new grains crystal growth and annexation of a few large new small recrystallized grains , and several other processes occur almost simultaneously complex process , based on deformation energy storage, grain boundary energy as the driving force , at different stages driven results can not simply traditional defined as the secondary recrystallization process .

( 3 ) Potassium bubble dispersion strengthening mechanism . Enhanced in a variety of materials, methods, dispersion strengthened (DS) is a second- phase strengthening , strengthening effect depends on the second phase of its chemical and thermodynamic stability , the ideal shape , small size , enough quantity and good dispersion . As a second phase of potassium bubbles all the conditions with the above , plus the size of the bubble and the dispersion K mode is controlled , but also shows the superiority of potassium bubbles , it has been classified as a number of dispersion strengthened in a distinctive strengthening mechanism . The second phase dispersion strengthened explain theoretical model matrix lot more is Orowan (Orowan) mechanism . Potassium bubble second phase particles as a special addition to causing diffusion rate decreases , increase the recrystallization temperature and thermal processing generate stable fibrous tissue and dislocation structures such as these Orowan strengthening indirectly strengthening mechanism , it must also see enhanced potassium bubble specificity, namely Asian organizations strengthening mechanisms . Ordered along the filament axis direction of potassium bubble column in processing fibrous form a distinct crystal growth , it is only at very high temperatures to form a clear long fibrous crystals and is very stable, and because of having abnormal , extreme aspect ratio large crystal growth and finger -shaped lock lap crystalline , less grain boundaries , especially grain boundaries transverse (perpendicular to the force of the grain boundaries ) less weakened creep at high temperatures plays a major role in the grain boundary sliding , thereby significantly improved tungsten -doped high-temperature creep strength. Research shows that the larger the aspect ratio , strength increase , the more significant aspect doped tungsten wire , usually above 20 . Experiments also showed that potassium bubbles on dislocation pinning attract and the more general second phase particles more powerful , its processing formed dislocation structure on the high-temperature strengthening greater role .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micro-Doped Lanthanum Tungsten Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:00

- Hits: 1451

A micro- lanthanum -doped tungsten preparation method comprises the following steps :

( 1 ) The paratungstate in high purity hydrogen reduction furnace in pre- reduced blue tungsten ;

( 2 ) Wet incorporation of potassium silicate , aluminum nitrate solution , dried by stirring the mixture , the potassium, silicon, aluminum, tungsten adsorbed in the gap to obtain a doped tungsten blue ;

( 3 ) The use of pressure guns lanthanum acid ammonia solution in spray form to place the doped tungsten blue spray doping pot while stirring , until after spray drying, to obtain amino acid lanthanum doped tungsten blue ; < br />

( 4 ) The blue tungsten doped lanthanum acid into ammonia reduction furnace in high purity hydrogen reduction reaction to obtain a reduction of lanthanum tungsten alloy coarse powder ;

( 5) Reducing the tungsten alloy powder of lanthanum quantitative hydrochloric acid, hydrofluoric acid washing to remove the excess dopant and other impurities to obtain lanthanum tungsten alloy powder ;

( 6 ) Using isostatic press kit to install the elastic modulus of lanthanum tungsten alloy powder is applied to the equal force , made of uniform density tungsten billet ;

( 7 ) Hydrogen tungsten billet under the protection of pre- sintered to obtain a pre-sintered article ;

( 8 ) Pre-sintered in hydrogen under the protection of vertical melt sintering , melting sintering get vertical bar ;

( 9 ) Using the swaging equipment carried on the vertical melt sintering of forging, sintering of the vertical melt gradually reduced cross-section , the length increases, billet within the organizational structure of the tungsten grains and surface condition changes state to prepare tungsten rod ; < br />

( 10 ) Annealing the tungsten rod ; ( 11 ) the annealed then swaging tungsten rod having a diameter of 3.7mm tungsten rod ;

( 12 )On the turntable for coarse tungsten rod tension , tungsten rod through the die holes turntable after the cross section is reduced, increase in length , to obtain a crude tungsten wire ;

( 13 ) The crude tungsten in air by flame oxidation anneal , and after the coating of graphite and a small compression ratio, single stretch, eliminate work hardening and reduce the tensile strength filament ;

( 14) The crude tungsten single stretched via a plurality of the desired motif is drawn into thin tungsten wire. Moreover , in step ( 7 ) in the pre-sintering temperature of 1200 ~ 1400 ° C, sintering time 30 to 50 minutes.

Moreover , in step ( 3 ) in the vertical melt temperature of the final sintering sink 50 ~ ^ 50 ° C, the sintering time is 60 to 70 minutes to obtain the vertical melt density of sintered article 17. 2 ~ 17. 6g/cm3.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Potassium-Doped Tungsten Bulbs Strengthen

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:52

- Hits: 1877

Doped tungsten containing potassium atoms due to air bubbles leaving the high-temperature creep resistance tungsten improve mechanisms . In 1918, Americans Perth (A.Pacz) found that tungsten oxide reduction by adding trace amounts of silicon, aluminum , potassium oxide billet prepared by appropriate processing and heat treatment made of tungsten wire has excellent high temperature creep resistance , is ideal incandescent filament material . Doped tungsten is still electronic , electric light source industry is an important basic material . The invention and production of doped tungsten although half a century of history, but due to the testing conditions , people on the micro- doping and Strengthening Mechanisms long failed to recognize , at different times have raised a variety of assumptions and inferences to explain . Therefore, doping and strengthening mechanisms always is a worldwide concern one of the few research topics .

Doped tungsten ordered the formation of potassium -doped tungsten bulb is caused by high-temperature creep resistance excellent basis for this argument is not only fully proved , but gradually made a convincing theoretical explanation , thus forming strengthening and improvement of the potassium bubble theory . Potassium -doped tungsten bulbs and perfect the mechanism of strengthening due to development, has become one of a variety of ways to strengthen the development of new refractory metal materials in the applications.

Potassium reinforcement theory of bubble formation and development can be divided into the following three phases :

( 1 ) Assuming the inference stage . 1957 Si Wolin (R.A.Swalin) and Geissler (A.H.Geisler) proposed a linear arrangement , said dopant , that the doping agent is added during the sintering of tungsten billet maintained during long time the porous state, so that recrystallization grains are fully grown . Reich (G.D.Reich) , who also made a similar linear arrangement dopant , said that the tungsten wire drawing process dopants in a tubular tungsten bronze compounds exist in the form fibers borders , these parallel filaments axis direction is tube-like in the recrystallization process will prevent or inhibit grain growth along the direction of the wire diameter , thereby forming a great aspect ratio of crystal growth . 1962 Milner (T.Miller) dissolving said dopant is proposed that a very small part of the dopant in dissolved form, dissolved particles and the interaction between dislocations , resulting in recrystallization grains grow to form . All these ideas corporations inferences and assumptions , the lack of adequate experimental basis , but to attract people's attention and promote further research has played a positive role.

( 2 ) theory and development phase. In 1967 , the library (R.C.Koo) , who used directly observed by transmission electron microscopy to annealing at a high temperature in the presence of tungsten dopant pressure generated by the vapor formed vesicles period Snow (D.B . Snow) confirmed the vesicles containing potassium atoms. Scholars from various countries were followed by X-ray energy dispersive spectroscopy , secondary ion mass spectroscopy , Auger electron spectroscopy and field ion microscope analysis of the most advanced electronic equipment for various states of doped tungsten microstructure and dopant the morphology and composition of the full system, experiments were observed and the results of each assay , based on the proposed mechanism of doped tungsten strengthen various theoretical explanation . Which the United States Library , Snow and China , who left Tieyong made a more systematic analysis of experimental and theoretical explanations. 1967 to 1985 is potassium -doped tungsten bulbs reinforcement theory with precise experimental basis and the establishment and development period.

( 3 ) potassium bubble theory to the development of new high-strength material phase. Since 1985 , successive refractory metals and hard materials, the International Conference on Theoretical study on the expansion of the bubble potassium and materials to strengthening and toughening materials in the field of basic issues that combine in-depth study of trace impurities on the tungsten, molybdenum grain between adhesion and the electronic structure of grain boundaries , leading to embrittlement microscopic mechanism , and then discusses the harmful effects of eliminating impurities technical measures . In addition , the different regions at different temperatures additive dispersion strengthening and potassium doped tungsten bulbs strengthening mechanisms linking explore refractory material suitable for a variety of strengthening mechanisms combined effects of reinforcement theory . Strengthening and toughening mechanisms for a correct understanding of the design and development of new high-temperature materials provides a theoretical basis .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com