What Are the Preparation methods of Tungsten Disulfide?

- Details

- Category: Tungsten Information

- Published on Thursday, 06 March 2025 16:40

- Written by Xiaoting

- Hits: 272

Tungsten disulfide (WS₂), a transition metal sulfide, typically appears as a gray-black powder. It exhibits excellent lubricating properties with a low friction coefficient and maintains stability under extreme conditions such as high temperature and pressure, making it commonly used as a solid lubricant. Additionally, it shows promising application potential in fields such as catalysis, energy storage, and semiconductors, positioning it as a highly regarded multifunctional inorganic material.

Read more: What Are the Preparation methods of Tungsten Disulfide?

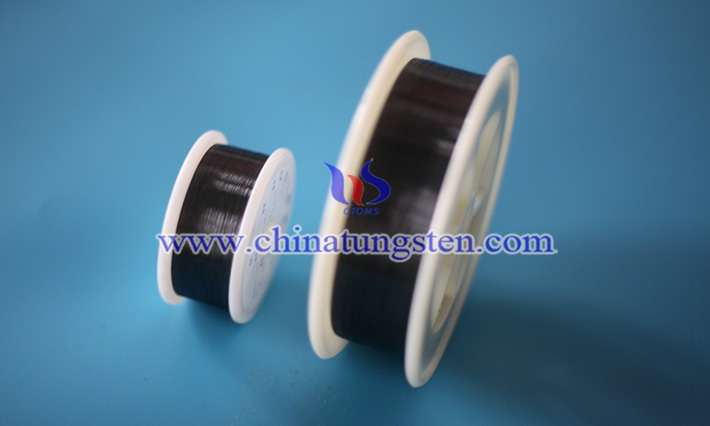

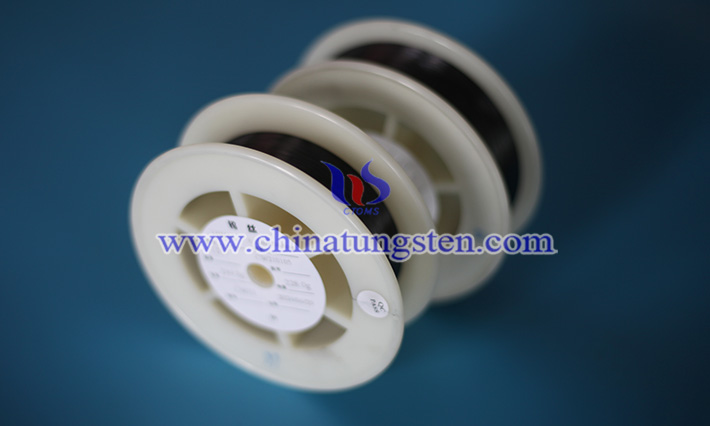

Applications of Halogen Lamp Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 March 2025 17:30

- Written by Shuxia

- Hits: 269

Due to its excellent high-temperature resistance, long lifespan, high luminous efficiency, and stability, halogen lamp tungsten wire is widely used across various fields. Whether in home lighting, automotive illumination, professional stage lighting, or industrial applications, it demonstrates unique advantages.

Technical Requirements of Halogen Lamp Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 March 2025 17:24

- Written by Shuxia

- Hits: 223

The production of halogen lamp tungsten wire is a complex and precise process, involving multiple steps such as tungsten powder preparation, tungsten rod forming, wire drawing, annealing, and surface treatment.

Read more: Technical Requirements of Halogen Lamp Tungsten Wire

Advantages of Halogen Lamp Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 March 2025 17:27

- Written by Shuxia

- Hits: 242

Halogen lamps are a specialized type of light source widely used in lighting, automotive, stage, and other applications.

Manufacturing Process of Halogen Lamp Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 March 2025 17:20

- Written by Shuxia

- Hits: 232

Halogen lamps are high-efficiency and long-lasting light sources, widely used in home lighting, automotive headlights, and stage lighting. One of their core components is tungsten wire, which plays a critical role in the high-temperature environment inside the lamp.

Read more: Manufacturing Process of Halogen Lamp Tungsten Wire

sales@chinatungsten.com

sales@chinatungsten.com