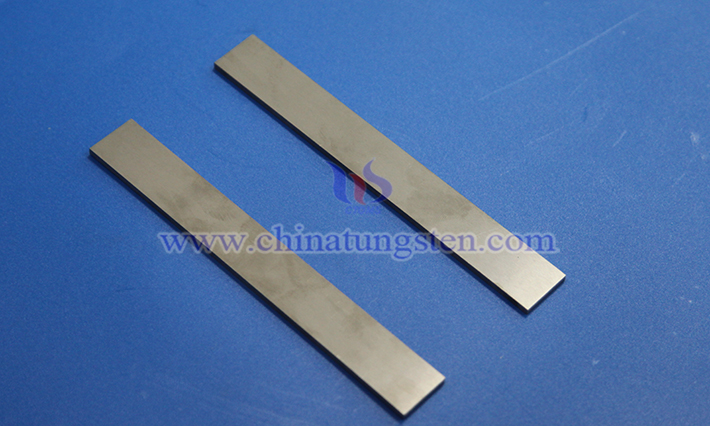

Steel-Bonded Hard Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 September 2025 14:20

- Written by Xiaoting

- Hits: 142

As a type of hard alloy, steel-bonded hard alloy combines the excellent properties of hard compounds and steel, primarily used in the manufacturing of wear-resistant parts and machine components. Below is an introduction to the basic information about this alloy material.

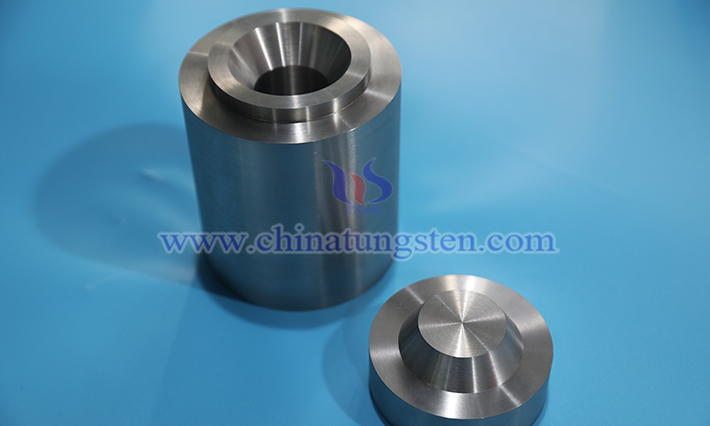

Tungsten Alloy Shielding Component

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 September 2025 14:10

- Written by Xiaoting

- Hits: 130

Compared to traditional shielding materials such as iron, lead, and cement, tungsten alloy shielding components offer superior overall performance. For instance, under the same thickness and working conditions, tungsten alloy shielding materials provide better or longer-lasting shielding effectiveness and service life than traditional materials. Moreover, it is a non-toxic, environmentally friendly, and non-radioactive material, thus posing no secondary harm to the ecosystem. Below is an introduction to the basic information about these alloy shielding components.

Requirements of Diamond Wire for Tungsten Core Wire

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2025 19:28

- Written by Xiaoting

- Hits: 123

As one of the primary cutting tools for high-hardness brittle materials, the quality of diamond wire depends not only on the production method, the size and distribution density of diamond particles, but also on the performance and thickness of the tungsten wire core. Generally, cutting wire produced using an electroplating process offers stronger cutting ability compared to that made with resin binders, primarily due to better diamond consolidation. The size of diamond particles should be moderate and evenly distributed; if the particles are too large, the cutting wire becomes too thick, increasing silicon wafer loss rates, whereas if they are too small, the cutting effectiveness decreases.

Read more: Requirements of Diamond Wire for Tungsten Core Wire

Reason for Adding Rare Earth Oxides to Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 September 2025 14:07

- Written by Xiaoting

- Hits: 127

Metal tungsten, due to its high melting point, strong electron emission capability, and low vapor pressure, has become the preferred choice for thermionic emission materials. However, its high electron work function, elevated electrode tip temperature, and tendency for grain growth lead to unstable arc beams, difficult arc initiation, and a short service life in pure tungsten electrodes, limiting their use to alternating current welding. To overcome these drawbacks, manufacturers often add rare earth oxides with low electron work functions, such as lanthanum oxide, cerium oxide, and yttrium oxide, to pure tungsten materials. This not only increases the recrystallization temperature of the product but also enhances electron emission.

Read more: Reason for Adding Rare Earth Oxides to Tungsten Electrodes

Tungsten Alloy Ring

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2025 15:40

- Written by Xiaoting

- Hits: 152

In daily life, as you pass by a machining workshop, you might catch a glimpse of a shiny metal ring on a robotic arm. Step into a medical device research lab, and you might find it quietly nestled within a critical piece of equipment. These rings, though seemingly ordinary, have a unique "heritage"—they are tungsten alloy rings.

sales@chinatungsten.com

sales@chinatungsten.com