Lanthanum And Lanthanum Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 11 October 2013 15:14

- Hits: 1877

Lanthanum is a chemical element , its chemical symbol is La, its atomic number is 57 , belonging to the  lanthanide elements for rare earth metals is the most reactive metal in the air is easily oxidized. Lanthanum quarry alone accounted for 25% of total rare earth . A soft silver-white metal , malleable . With water effect. Soluble in dilute acid . Easily oxidized in air ; heating can burn to form oxides and nitrides. Heated in hydrogen generation hydride . It is the second most abundant rare earth elements , often along with other rare earth elements present in monazite , fluorocarbon lanthanum strontium ore . It is uranium, thorium or plutonium fission of radioactive products . It gives the refractive index of the special properties of the glass , the glass having a higher refractive index . Preparation of lanthanum general dehydration of hydrated lanthanum chloride , the use of calcium metal restore , or anhydrous lanthanum chloride electrolysis and after melting in the system. Used to manufacture an expensive camera lens . 138La is a radioactive half-life of 1.1 × 1011 , the trial was to treat cancer .

lanthanide elements for rare earth metals is the most reactive metal in the air is easily oxidized. Lanthanum quarry alone accounted for 25% of total rare earth . A soft silver-white metal , malleable . With water effect. Soluble in dilute acid . Easily oxidized in air ; heating can burn to form oxides and nitrides. Heated in hydrogen generation hydride . It is the second most abundant rare earth elements , often along with other rare earth elements present in monazite , fluorocarbon lanthanum strontium ore . It is uranium, thorium or plutonium fission of radioactive products . It gives the refractive index of the special properties of the glass , the glass having a higher refractive index . Preparation of lanthanum general dehydration of hydrated lanthanum chloride , the use of calcium metal restore , or anhydrous lanthanum chloride electrolysis and after melting in the system. Used to manufacture an expensive camera lens . 138La is a radioactive half-life of 1.1 × 1011 , the trial was to treat cancer .

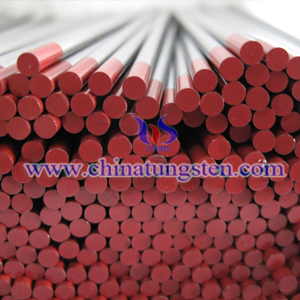

Lanthanum tungsten electrode is the European country in the 1980s with the hope for alternative thorium tungsten products, improved varieties, once launched, its excellent welding performance attracted much attention in the international welding industry and is very popular, especially by European Welding School in the pursuit, for this reason, the export volume of lanthanum tungsten electrode tungsten thorium behind , while in the domestic market awareness is not high. Its characteristics are the closest conductive properties of 2% thoriated tungsten electrodes , durable high burning rate of the current minimum .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cerium And Cerium Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Friday, 11 October 2013 15:11

- Hits: 2085

Cerium is a chemical element , its chemical symbol Ce, atomic number 58 , atomic weight 140.115 , belonging to the lanthanide elements, but also one of the rare earth elements . Element name comes from the asteroid Ceres, the English name . 1803 German chemist Klaproth , Swedish chemist Berzelius discovered the cerium oxide , respectively . Cerium has four kinds of natural stable isotopes : cerium 136,138,140,142 . Cerium content in the crust of about 0.0046% , is the most abundant of the rare earth elements . Gray soft metal . In monazite accounted for over 40% of total rare earth . Cerium chemically active , firing in air using Daogua ie , soluble in acid , insoluble in alkali . Cerium is iron gray metallic , malleable , melting point 799 ° C, the boiling point of 3426 ° C, density of 6.657 g / cm ³. Cerium is in addition to the rare earth elements europium outside the most active . Cerium oxide at room temperature, it is easy ; slow decomposition in cold water , hot water reaction speed ; most cerium salt solution as its orange-red to orange-yellow , with a strong anti- magnetic properties and oxidation. Cerium oxide for polishing precision glass products, but also do glass to color agent and used to produce colored glass , cerium nitrate used in the manufacture incandescent hood .

Cerium is a chemical element , its chemical symbol Ce, atomic number 58 , atomic weight 140.115 , belonging to the lanthanide elements, but also one of the rare earth elements . Element name comes from the asteroid Ceres, the English name . 1803 German chemist Klaproth , Swedish chemist Berzelius discovered the cerium oxide , respectively . Cerium has four kinds of natural stable isotopes : cerium 136,138,140,142 . Cerium content in the crust of about 0.0046% , is the most abundant of the rare earth elements . Gray soft metal . In monazite accounted for over 40% of total rare earth . Cerium chemically active , firing in air using Daogua ie , soluble in acid , insoluble in alkali . Cerium is iron gray metallic , malleable , melting point 799 ° C, the boiling point of 3426 ° C, density of 6.657 g / cm ³. Cerium is in addition to the rare earth elements europium outside the most active . Cerium oxide at room temperature, it is easy ; slow decomposition in cold water , hot water reaction speed ; most cerium salt solution as its orange-red to orange-yellow , with a strong anti- magnetic properties and oxidation. Cerium oxide for polishing precision glass products, but also do glass to color agent and used to produce colored glass , cerium nitrate used in the manufacture incandescent hood .

Thorium Tungsten Electrode of The Origin And Development

- Details

- Category: Tungsten Information

- Published on Friday, 11 October 2013 15:01

- Hits: 1816

Stainless steel electrode melting point of pure tungsten (3650K), the electron emission capability, high  modulus , low vapor pressure , the first to be used as an electron -emitting material , but the pure tungsten emission efficiency is low , and in the formation of a high temperature recrystallization equiaxed grain structure will become brittle and easy to break. To overcome these shortcomings , countries Materials workers dedicated to research and development of new electrode materials , tungsten -based doping several high melting point, low power electronic escape rare earth metal oxides, can improve the recrystallization temperature , and can activate the electron emission . However, in the rare earth tungsten electrodes on the basis of research , despite some achievements , but the current global market, replace the use of tungsten electrodes still a long way .

modulus , low vapor pressure , the first to be used as an electron -emitting material , but the pure tungsten emission efficiency is low , and in the formation of a high temperature recrystallization equiaxed grain structure will become brittle and easy to break. To overcome these shortcomings , countries Materials workers dedicated to research and development of new electrode materials , tungsten -based doping several high melting point, low power electronic escape rare earth metal oxides, can improve the recrystallization temperature , and can activate the electron emission . However, in the rare earth tungsten electrodes on the basis of research , despite some achievements , but the current global market, replace the use of tungsten electrodes still a long way .

1913 Pinch (Pintsch) found that tungsten - thorium dioxide electrode material in pure tungsten with 2% ( mass fraction ) of about thorium dioxide , which escapes power reduction is reduced to nearly half of 2.63eV ( pure tungsten is 4.55eV), greatly improving the emission efficiency of up to 50mA / W ~ 70mA / W ( pure tungsten electrodes by carbonization only 25mA / W ~ 40mA / W). Moreover tungsten - arc thorium dioxide and stability performance greatly improved than that of pure tungsten . But thorium is a natural radioactive elements, its long half-life of α -ray 1.4 × 1014 years, the production and use of radioactive pollution on the environment and human health hazard ; growing environmental awareness restricts its development, but tungsten - thorium dioxide electrode arc stability and durability can not meet the growing demand for welding technology , so countries have been conducting research materials and workers to develop new generation of thorium tungsten electrode material .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Lanthanum Tungsten Electrode of The Origin And Development

- Details

- Category: Tungsten Information

- Published on Friday, 11 October 2013 15:04

- Hits: 1957

Stainless steel electrode melting point of pure tungsten (3650K), the electron emission capability, high modulus , low vapor pressure , the first to be used as an electron -emitting material , but the pure tungsten emission efficiency is low , and at a high temperature to form equiaxed recrystallized shaped grains become brittle and easy to break. To overcome these shortcomings , countries Materials workers dedicated to research and development of new electrode materials , tungsten -based doping several high melting point, low power electronic escape rare earth metal oxides, can improve the recrystallization temperature , and can activate the electron emission . However, in the rare earth tungsten electrodes on the basis of research , despite some achievements , but the current global market, replace the use of tungsten electrodes still a long way .

In our country the 1990s, in order from the system with excellent performance and pollution tungsten electrode, tungsten trioxide powder of lanthanum oxide is added , after reduction , suppression, melt down , swaging , stretching lanthanum tungsten electrode was obtained . After analysis, the lanthanum of the tungsten electrode electrical performance than cerium tungsten and tungsten thorium , lanthanum, tungsten and lanthanum oxide evaporation rate is low migration rate , to form a better lap dovetail microstructure , has good high temperature resistance creep. High-energy ball milling and vacuum hot pressing sintering prepared bulk nanocrystalline tungsten - lanthanum oxide electrode materials, the effects of different lanthanum oxide nanocrystalline tungsten content on the electrical properties of the electrode material , while using scanning electron microscopy and energy dispersive spectrometer measured fuel La arc electrode tip distribution and microstructure . The results showed that: nanocrystalline tungsten - lanthanum oxide electrode was superior to the conventional powder metallurgy coarse-grained tungsten electrodes . When the lanthanum oxide content of 6% to 8% , the thermal electron emission capability and stability of the best , but with increasing the content of rare earth lanthanum oxide , lanthanum tungsten electrode moldability and processability more difficult.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cerium Tungsten Electrodes Origin And Development

- Details

- Category: Tungsten Information

- Published on Friday, 11 October 2013 14:57

- Hits: 1794

Stainless steel electrode melting point of pure tungsten (3650K), the electron emission capability, high  modulus , low vapor pressure , the first to be used as an electron -emitting material , but the pure tungsten emission efficiency is low , and in the formation of a high temperature recrystallization equiaxed grain structure will become brittle and easy to break. To overcome these shortcomings , countries Materials workers dedicated to research and development of new electrode materials , tungsten -based doping several high melting point, low power electronic escape rare earth metal oxides, can improve the recrystallization temperature , and can activate the electron emission . However, in the rare earth tungsten electrodes on the basis of research , despite some achievements , but the current global market, replace the use of tungsten electrodes still a long way .

modulus , low vapor pressure , the first to be used as an electron -emitting material , but the pure tungsten emission efficiency is low , and in the formation of a high temperature recrystallization equiaxed grain structure will become brittle and easy to break. To overcome these shortcomings , countries Materials workers dedicated to research and development of new electrode materials , tungsten -based doping several high melting point, low power electronic escape rare earth metal oxides, can improve the recrystallization temperature , and can activate the electron emission . However, in the rare earth tungsten electrodes on the basis of research , despite some achievements , but the current global market, replace the use of tungsten electrodes still a long way .

Cerium tungsten is to replace thoriated tungsten contamination with radioactive material and developed a new type of tungsten electrode material , the former Soviet Union in the 1960s, the development of new electrode materials have been reported , China's Shanghai bulb factory in 1973 began to study the W-CeO2 electrode , the first successful trial and application of the International organization for Standardization and has been included in non- melting polar standards . Most foreign countries, the use of pure tungsten powder mixed with cerium compounds prepared to take direct cerium tungsten powder. Country through the use of wet blue tungsten doped ceria , disposable reduction, pickling, isostatic pressing , rolling and other processes developed by cogging cerium tungsten electrodes , tested and used to indicate that the developed cerium tungsten powder of high purity, good suppression performance and sintering properties ; cerium cerium tungsten blanks content uniformity , good processing properties . Electrodes consistency, arc , good performance, the user has won wide acclaim. Practice has proved that the small size of cerium tungsten electrode tungsten electrode welding succeeded in replacing thoriated tungsten , but in AC welding electrodes , gas discharge light source and other aspects still can not completely replace thoriated tungsten , cerium tungsten electrodes and there arc poor life expectancies and other deficiencies.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com