Applications of Tungsten Wire in Glass Molding

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:31

- Written by Zhenghua

- Hits: 3

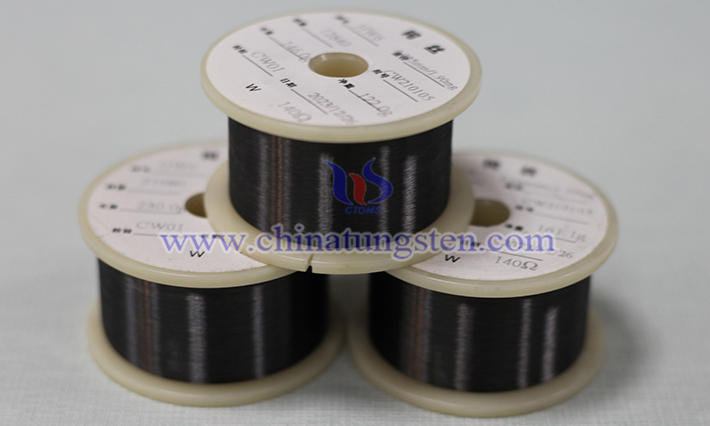

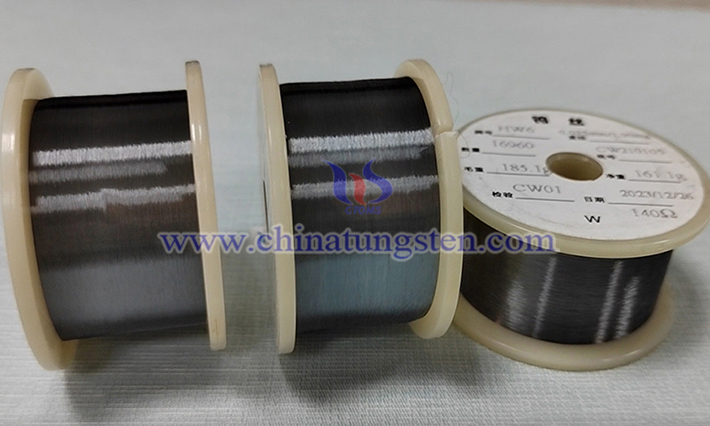

Tungsten wire is widely used in the industrial field, especially in the glass molding process, due to its high melting point, corrosion resistance and excellent mechanical properties. Tungsten wire is mainly used in key links such as heating, cutting and molding in glass manufacturing, and its unique properties can meet the needs of high temperature and complex process environments.

I. Characteristics and Applicability of Tungsten Wire

Tungsten wire is known for its extremely high melting point (about 3422°C), which enables it to perform well in the high temperature environment of glass molding. Glass molding usually requires the raw materials to be heated to more than 1000°C, and tungsten wire can maintain stable physical properties at such high temperatures and is not easy to deform or melt. In addition, tungsten wire has good electrical and thermal conductivity, can quickly respond to heating needs, and ensure the accuracy of the process. Its oxidation resistance and corrosion resistance also give it a long service life in the chemical environment of glass melting.

II. Main Applications of Tungsten Wire in Glass Forming

1. Glass Melting and Heating

Tungsten wire is often used as a heating element in the glass manufacturing process. For example, in a glass melting furnace, tungsten wire can be processed into a resistance heating wire to provide a stable high-temperature environment to melt glass raw materials. Since tungsten wire can withstand extremely high temperatures, it can ensure that the glass raw materials are evenly heated in electric heating equipment, thereby ensuring product quality. In addition, the high thermal conductivity of tungsten wire makes it excellent in local heating scenarios, such as in the molding of small glass products.

2. Glass Cutting and Trimming

Tungsten wire also has important applications in glass cutting. High-temperature tungsten wire can be used as a thermal cutting tool to soften or break the glass at a specific location through local high temperature to achieve precise cutting. This method is particularly common in the production of thin-walled glass products or glass devices with complex shapes. The high strength and wear resistance of tungsten wire enable it to maintain accuracy during repeated cutting and reduce equipment maintenance costs.

3. Glass Forming Molds and Auxiliary Tools

Tungsten wire can also be used to make auxiliary parts for glass forming molds. For example, when blowing or stretching glass products, tungsten wire can be used as a support or guide element to help shape the glass into a specific shape. Due to the rigidity and high temperature resistance of tungsten wire, it can withstand the mechanical stress and high temperature environment generated during the glass forming process, thereby improving the service life of the mold and the molding accuracy of the product.

III. Advantages and Challenges of Tungsten Wire Application

The main advantages of tungsten wire in glass forming include its high temperature resistance, corrosion resistance and high strength, which make it an ideal material for high temperature processes. In addition, the processing flexibility of tungsten wire allows it to be made into various shapes and sizes to meet different production needs. However, tungsten wire also has some challenges, such as its high production cost and possible oxidation under extreme conditions. To overcome these problems, the industry often extends its life by coating the surface of tungsten wire with a protective layer or using it in an inert gas environment.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com