What is Molybdenum Bar?

- Details

- Category: Tungsten Information

- Published on Thursday, 05 June 2025 17:55

- Written by Xiaoting

- Hits: 5

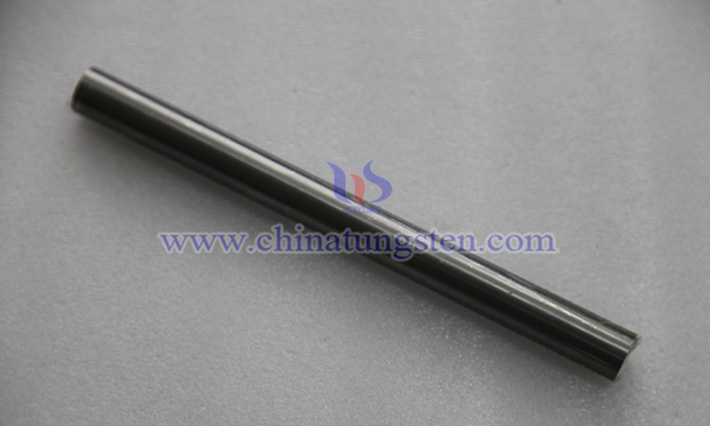

Molybdenum bar is a rod-shaped product made primarily from high-purity molybdenum, with a purity of up to 99.7%. Renowned for its excellent thermal, mechanical, chemical, and electrical properties, it serves as a core foundational material in key industries such as metallurgy and power equipment.

Molybdenum bar inherits the outstanding attributes of metallic molybdenum. In its natural state, the surface displays a bright, silvery metallic luster; when processed with special techniques involving lubricants or oxide coatings, it takes on a black appearance. With a high melting point and density, molybdenum bar offers shape stability and high strength under high-temperature conditions. It also exhibits excellent mechanical properties, with high strength and hardness to withstand complex mechanical stresses, and a low thermal expansion coefficient to maintain dimensional accuracy during significant temperature changes—preventing structural failure due to thermal deformation. In terms of electrical and thermal conductivity, molybdenum bar performs exceptionally, efficiently conducting current and dissipating heat, making it suitable for equipment with stringent thermal management requirements. Additionally, its good chemical stability provides strong corrosion resistance in typical environments, ensuring long-term reliability across various conditions.

The production of molybdenum bar involves multiple rigorous steps:

Raw Material Pretreatment: Starting with molybdenite concentrate, it is roasted to convert molybdenum sulfide into oxide, facilitating further processing.

Leaching and Purification: The roasted product is mixed with ammonia water to form an ammonium molybdate solution; impurities are removed through purification, followed by neutralization with hydrochloric acid to crystallize ammonium polymolybdate. This is then dissolved and evaporated to yield ammonium paratungstate.

Calcination and Reduction: Ammonium paratungstate is calcined to produce molybdenum trioxide, which is reduced with hydrogen to obtain high-purity molybdenum powder.

Forming and Sintering: The molybdenum powder is pressed, shaped, and sintered at high temperatures to form a dense molybdenum bar product.

Types and Applications

Rectangular bar: Suitable for scenarios requiring large-area contact or special structural assembly (e.g., industrial mold manufacturing).

Cylindrical bar: The most common form, widely used in machining and electrode production for turning, drilling, and other processes.

Alkali-washed bar: Treated with an alkaline solution (e.g., sodium hydroxide, sodium carbonate, or trisodium phosphate) to remove scale, resulting in a smooth, uniform gray metallic luster—ideal for applications demanding high surface cleanliness.

Ground bar: Processed through coarse, medium, and fine grinding to achieve high surface finish, suited for precision component manufacturing with strict accuracy requirements.

Turned bar: Machined on a lathe for a flat but relatively rough surface, used where mechanical performance matters more than surface finish.

Polished bar: Treated with mechanical, chemical, or electrochemical polishing to significantly reduce roughness, yielding a mirror-like finish—commonly used in electronics and high-end optical equipment requiring superior surface quality.

Standard bar: Primarily used to produce molybdenum wire via drawing, applicable in electric light sources and electronic components.

High-temperature bar: Leveraging excellent performance in high-temperature environments, it is used to make high-strength wire-cutting molybdenum wire, high-temperature heating elements, light source materials, and structural components—meeting demands in aerospace and metallurgy.

Steelmaking bar: Added as a steel alloying agent during steelmaking, it enhances the steel’s high-temperature strength, toughness, and corrosion resistance.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129595/5129696 Email:sales@chinatungsten.com |

| Tungsten News & Prices: Chinatungsten Online news.chinatungsten.com | Molybdenum News & Molybdenum Price: news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com