Yttrium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 05 June 2025 17:50

- Written by Xiaoting

- Hits: 3

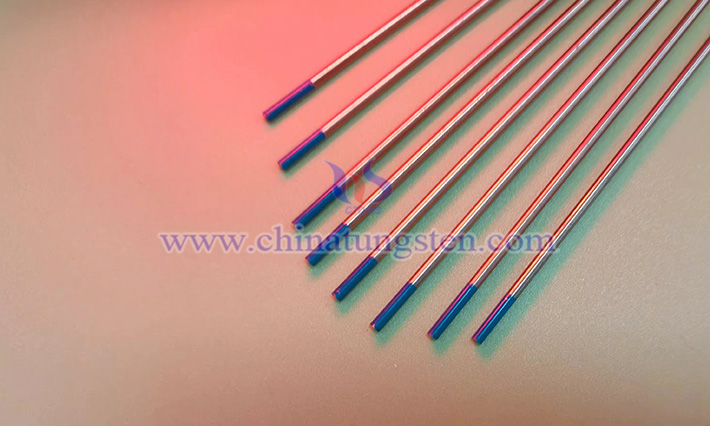

Yttrium tungsten electrode, a typical rare earth tungsten electrode, is a high-performance electrode material created by modifying a high-purity tungsten base with an appropriate amount of yttrium oxide (Y₂O₃). Its English name is Yttrium Tungsten Electrode. The commonly used WY20 grade in the industry is identified by a blue color-coded tip for quick recognition among various electrode products. It comes in perse specifications, with diameters ranging from 0.5mm to 12.0mm to suit different power welding equipment, and standard lengths typically set at 150mm or 175mm to meet various welding operation needs.

Yttrium tungsten electrode effectively combines the advantages of pure tungsten electrodes and yttrium oxide. Leveraging tungsten’s extremely high melting point, the electrode maintains structural stability in high-temperature welding environments. The addition of yttrium oxide significantly enhances its overall performance: it increases the recrystallization temperature, improving resistance to high-temperature deformation and preventing breakage during welding; it also, with yttrium oxide’s low electron work function, greatly enhances electron emission, resulting in excellent arc initiation—rapid and stable arc ignition, uniform arc column, and a low burn rate. Additionally, the electrode exhibits superior electrical and thermal conductivity, good corrosion resistance, and oxidation resistance.

The production of yttrium tungsten electrodes adheres to strict technical standards: initially, spray doping is used to evenly disperse a yttrium nitrate solution into ammonium paratungstate or tungsten trioxide, ensuring uniform yttrium oxide distribution; this is followed by high-temperature drying to form yttrium-tungsten coated powder. The powder then undergoes two reduction processes to convert it into uniformly dispersed yttrium-tungsten powder. The powder is pressed and sintered at high temperatures to form dense yttrium-tungsten billets, providing high strength and a robust internal structure. Finally, multiple forging steps refine the grain structure and optimize the material’s organization, yielding the final product.

Due to its superior performance, yttrium tungsten electrode is the preferred choice for welding military and aerospace components, where welding quality standards are extremely high. Its stable arc characteristics and low burn rate ensure welds with excellent strength and stability. In industrial production, it is widely used for welding various metals, including carbon steel, stainless steel, and copper-aluminum alloys, demonstrating strong adaptability for both precision thin-sheet welding and deep-penetration thick-plate welding.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com