Physical Properties of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

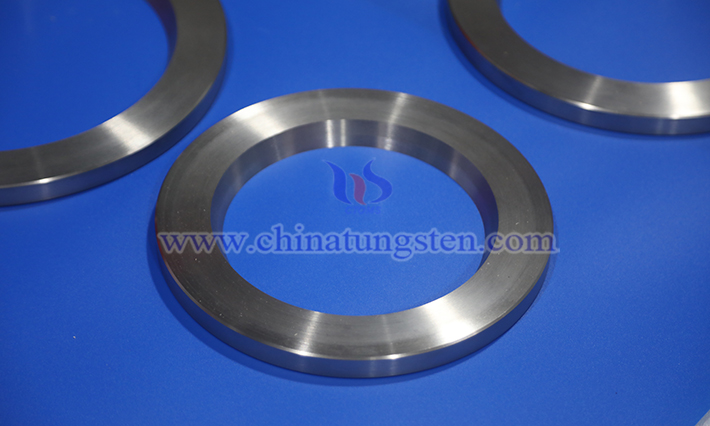

Tungsten-nickel-iron alloy is a material with tungsten as the matrix (typically 90%–98% tungsten content), formed by adding nickel, iron, and other elements. Its physical properties stem from the synergistic effect of tungsten’s high hardness and the toughness of the nickel-iron binder phase, which can be optimized by adjusting composition ratios and preparation processes.

Impact of Density on Tungsten-Nickel-Iron Alloy Applications

- Details

- Category: Tungsten Information

The density of tungsten-nickel-iron alloy, typically ranging from 17.0 to 18.5 g/cm³, is a critical factor influencing its application scenarios. This high-density characteristic profoundly impacts the alloy’s use across functional realization, structural design, and scenario adaptability.

Characteristics of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

Tungsten-nickel-iron alloy is a high-density alloy with tungsten as the base (typically 80%–98% tungsten content), incorporating nickel, iron, and other elements. It boasts a range of unique physical, chemical, and mechanical properties, finding wide use in aerospace, defense, medical devices, and industrial manufacturing.

Can Chrome Plating on Tungsten Alloy Surfaces Improve Corrosion Resistance?

- Details

- Category: Tungsten Information

Chrome plating on tungsten alloy surfaces can greatly enhance corrosion resistance. This is a common surface engineering technique used to improve durability and decorative appearance.

1. Basic Principle of Chrome Plating

Chrome plating—primarily referring to hard chrome plating—is an electrochemical process that deposits a dense chromium (Cr) layer on the surface of a metal. This chromium layer features:

- High hardness (HV800~HV1000)

- Excellent wear resistance and low friction coefficient

-

Good chemical stability and oxidation resistance

Applications of Tungsten Alloy Counterweight Blocks in the Automotive Field

- Details

- Category: Tungsten Information

High-density tungsten alloy, a functional material with tungsten as its base (85%–99%) combined with metals like nickel, iron, and copper through powder metallurgy sintering, boasts a density of 16–18.5 g/cm³ along with high strength, wear resistance, and corrosion resistance. In the automotive field, its core advantages as a counterweight block include precise weight adjustment in a small volume, minimizing space usage; strong chemical stability to withstand the high temperatures and humidity of engine compartments; and eco-friendliness, aligning with global automotive industry green standards.

What Is Zinc Tungstate?

- Details

- Category: Tungsten Information

Zinc tungstate (Tungsten Zinc, ZnWO₄), also known as zinc tungsten oxide, belongs to the tungstate family. It is formed by the chemical bonding of palent zinc ions (Zn²⁺) and tungstate ions [(WO₄)²⁻], resulting in a wolframite-type crystal structure. In semiconductor research, its photoelectric properties and catalytic activity offer new possibilities for developing novel optoelectronic devices and environmental purification materials, demonstrating significant application potential in energy and environmental fields.

What Is Potassium Tungstate?

- Details

- Category: Tungsten Information

Compared to sodium tungstate, potassium tungstate (K₂WO₄) exhibits distinct solubility and chemical reactivity due to the introduction of K⁺ ions. From its role as an intermediate in metallic tungsten production to its function as an additive in photovoltaic cell electrolytes, this compound leverages an intrinsic logic of "ionic properties-crystal structure-application" to build perse application scenarios in energy, materials, and analytical chemistry.

What Is Calcium Tungstate?

- Details

- Category: Tungsten Information

Compared to alkali metal tungstates (e.g., sodium tungstate and potassium tungstate), calcium tungstate (CaWO₄) exhibits markedly different crystal structures and properties due to the incorporation of Ca²⁺, evolving from its industrial designation as "synthetic scheelite" to its core application as a scintillator material.

What Is Magnesium Tungstate?

- Details

- Category: Tungsten Information

Within the family of inorganic functional materials, magnesium tungstate (MgWO₄) stands out as a representative alkaline earth metal tungstate, leveraging its unique crystal structure and perse properties to deliver significant value in optoelectronic displays, catalytic degradation, and functional ceramics. This compound, formed by magnesium ions (Mg²⁺) and tungstate ions [(WO₄)²⁻], inherits the stability of alkaline earth metals while gaining rich optical and electrical responses from the tungsten-oxygen framework, serving as a bridge between traditional chemistry and emerging optoelectronic technologies.

What Is Ferrous Tungstate?

- Details

- Category: Tungsten Information

Within the broad field of transition metal compounds, ferrous tungstate (FeWO₄) stands out as a representative example of an iron-group element combined with tungstate, gaining prominence in chemical and materials science research due to its unique physicochemical properties and versatile application potential. This tungstate, formed by Fe²⁺ and (WO₄)²⁻, not only inherits the magnetic commonality of iron-group elements but also exhibits rich functional characteristics due to the introduction of the tungsten-oxygen framework, opening new pathways in catalysis, energy storage, and inorganic material preparation.

sales@chinatungsten.com

sales@chinatungsten.com