Molybdenum Powder Exports Decreased by 90% in the First Half of 2025

- Details

- Category: Tungsten Video

In the first half of 2025, China’s molybdenum product exports were 19,220.53 tons, decreased by 3.86% year-on-year. Among these, molybdenum powder exports were 11.61 tons, decreased by 91.49%; molybdenum wire exports were 158.05 tons, increased by 10.96%; ferromolybdenum exports were 3,137.65 tons, decreased by 21.32%; ammonium molybdate exports were 189.20 tons, decreased by 33.32%; and other molybdenum products exports were 116.34 tons, decreased by 12.13%.

Ammonium Molybdate Imports Increased by 200% in the First Half of 2025

- Details

- Category: Tungsten Video

In the first half of 2025, China’s molybdenum product imports were 41,101.50 tons, increased by 22.19% year-on-year. Among these, molybdenum powder imports were 2.01 tons, increased by 4.08%; molybdenum wire imports were 19.79 tons, increased by 58.90%; ferromolybdenum imports were 2,821.46 tons, decreased by 28.61%; ammonium molybdate imports were 1,108.52 tons, increased by 205.45%; and other molybdenum products imports were 12.74 tons, increased by 24.01%.

Tungsten Trioxide Exports Decreased by 75% in the First Half of 2025

- Details

- Category: Tungsten Video

In the first half of 2025, China’s tungsten product exports were 7,257.99 tons, decreased by 23.94% year-on-year. Among these, tungsten powder exports were 659.23 tons, decreased by 29.53%; tungsten wire exports were 191.94 tons, increased by 11.87%; tungsten carbide exports were 588.57 tons, decreased by 71.48%; ammonium paratungstate exports were 162.50 tons, decreased by 42.52%; and tungsten trioxide exports were 350.48 tons, decreased by 76.24%.

Tungsten Trioxide Imports Decreased by 90% in the First Half of 2025

- Details

- Category: Tungsten Video

In the first half of 2025, China’s tungsten product imports were 8,698.06 tons, increased by 17.74% year-on-year. Among these, tungsten powder imports were 23.01 tons, increased by 46.56%; tungsten wire imports were 2,466 kilograms, decreased by 9.30%; tungsten carbide imports were 38.78 tons, decreased by 35.82%; ammonium paratungstate imports were 5 kilograms, increased by 25.00%; and tungsten trioxide imports were 6,837 kilograms, decreased by 88.83%.

[Know Tungsten] Tungsten Probe for Wafer Probe Cards

- Details

- Category: Tungsten Video

Tungsten probe is a precision testing tool made from high-purity tungsten, widely used for inspecting tiny components and electrical performance testing in the electronics, electrical, and semiconductor industries.

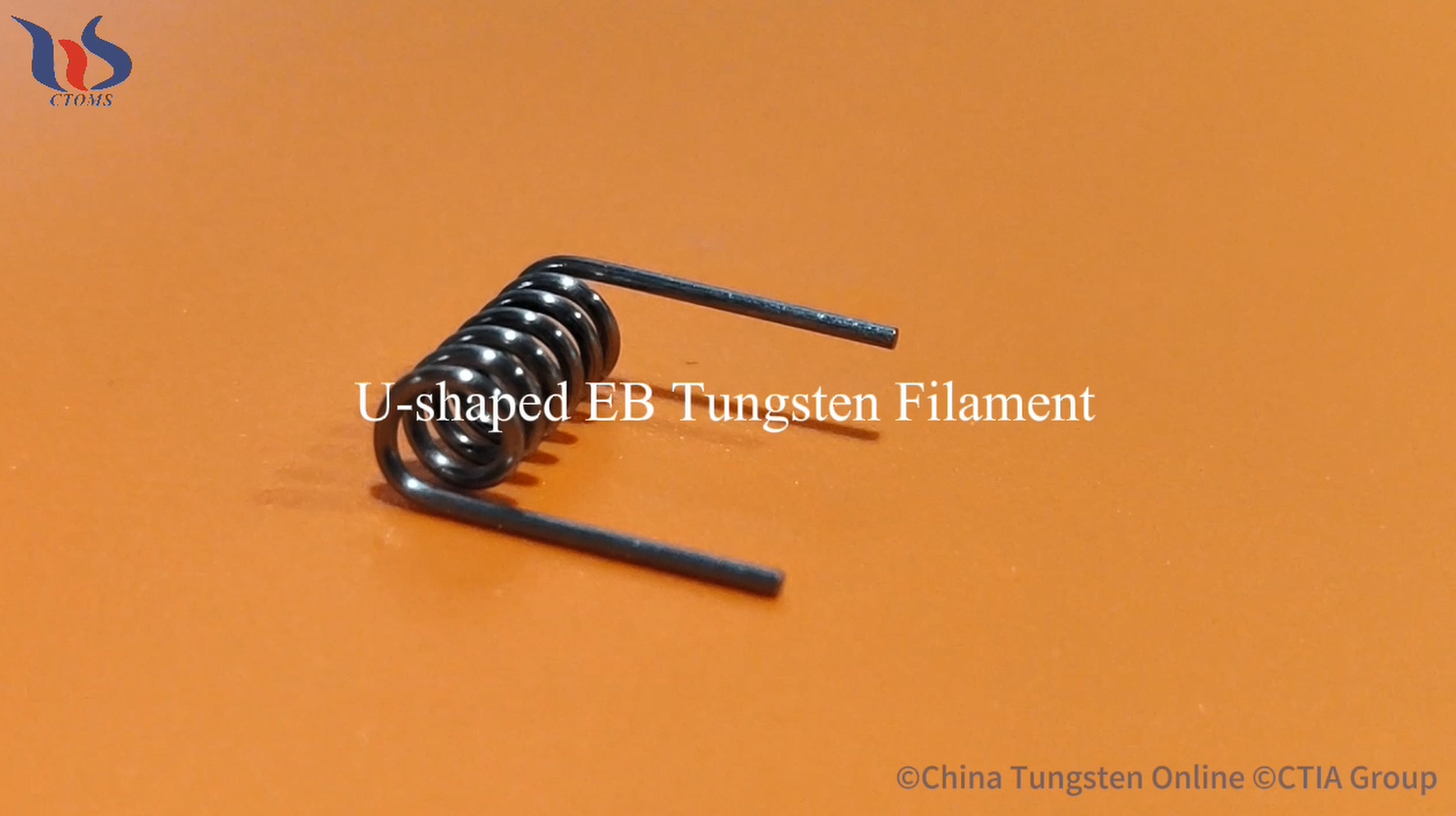

[Know Tungsten] The Performance of U-shaped EB Tungsten Filament

- Details

- Category: Tungsten Video

The U-shaped EB tungsten filament is a high-purity tungsten wire heating element bent into a U shape, widely used in electron beam evaporation coating equipment.

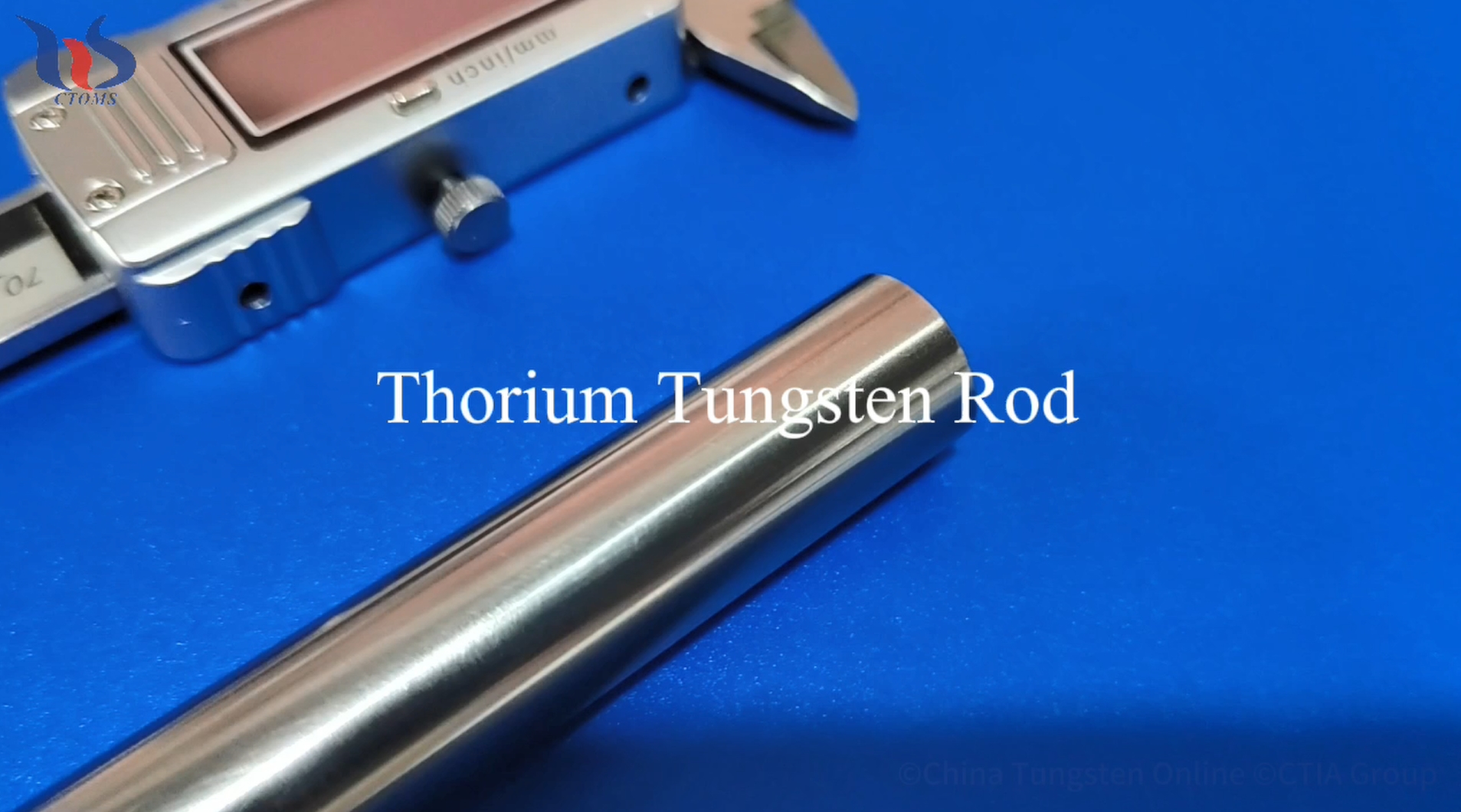

[Know Tungsten] High-Performance TIG Welding Choice: Thorium Tungsten Rod

- Details

- Category: Tungsten Video

Thorium tungsten rod is a tungsten alloy bar containing 2% thorium oxide, known for its excellent high-temperature strength, resistance to electron emission, and thermal stability.

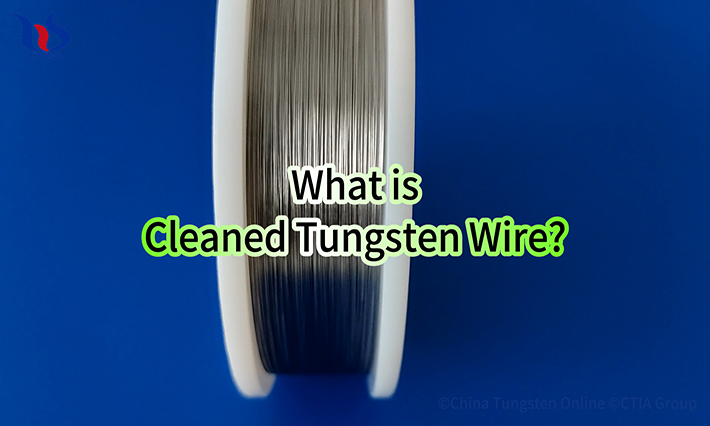

[Know Tungsten] What is Cleaned Tungsten Wire?

- Details

- Category: Tungsten Video

Cleaned Tungsten Wire, also known as white tungsten wire, does not refer to tungsten wire with a white surface, but refers to tungsten wire that has been electrolytically washed and polished. The surface of this tungsten wire is smooth and clean, without graphite emulsion attached, and presents a silver-gray metallic luster.

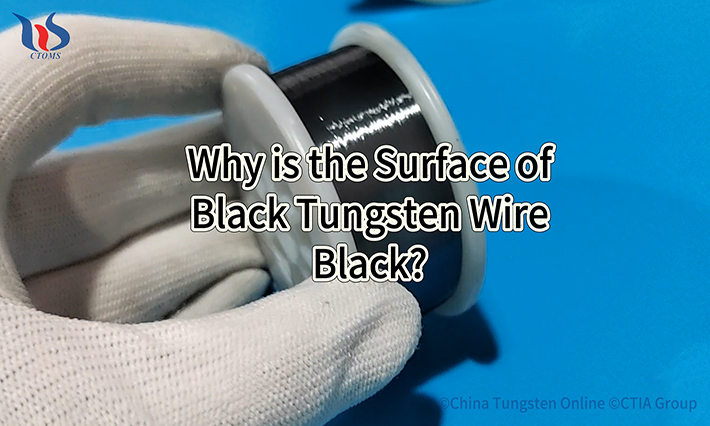

[Know Tungsten] Why is the Surface of Black Tungsten Wire Black?

- Details

- Category: Tungsten Video

The black surface of black tungsten wire is mainly because graphite emulsion is sprayed during the drawing process. As a lubricant, graphite emulsion can effectively reduce the friction coefficient between the tungsten wire and the drawing die, reduce the risk of tungsten wire breakage during the drawing process, and extend the service life of the drawing die. After the graphite emulsion adheres to the surface of the tungsten wire, a thin black coating will be formed, which is also the source of the appearance characteristics of black tungsten wire. The graphite layer can be removed by alkaline washing.

[Know Tungsten] Tungsten Wire for Photovoltaic Diamond Wire Saws

- Details

- Category: Tungsten Video

In the photovoltaic field, tungsten wire is generally used as a diamond wire base material for silicon wafer cutting. It has high toughness, high tensile strength, high temperature resistance, corrosion resistance and other characteristics. Compared with traditional high-carbon steel wire, tungsten wire has great potential for wire diameter refinement. At present, the diameter of tungsten wire used in diamond wire saws in the photovoltaic industry is about 25-35μm, which is only half the diameter of an adult hair. The diameter of high-carbon steel wire is usually 30-60μm. Wire diameter refinement can effectively reduce silicon wafer loss, meet the requirements of large-size and thin silicon wafer cutting, and help the photovoltaic industry reduce costs and increase efficiency.

sales@chinatungsten.com

sales@chinatungsten.com