Harnessing Efficiency: The Wonders of Tungsten Copper Heat Sinks

- Details

- Category: Tungsten's News

- Published on Tuesday, 06 February 2024 14:29

In the dynamic realm of electronics, where innovation is the heartbeat, ensuring optimal performance while managing heat becomes an integral challenge.

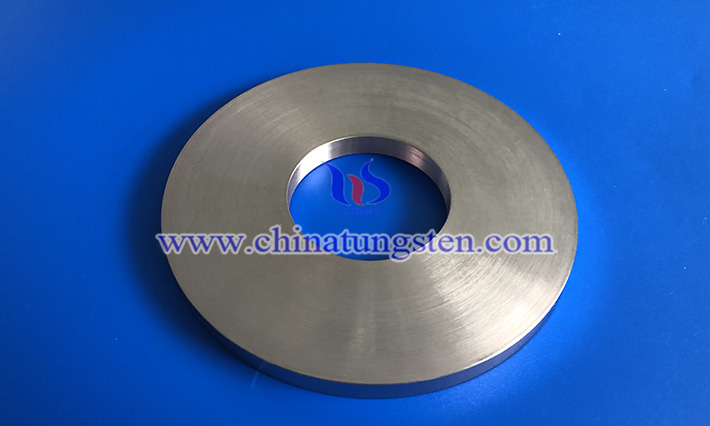

Tungsten copper heat sinks emerge as unsung heroes, seamlessly blending the robust characteristics of tungsten with the thermal prowess of copper. This composite material plays a pivotal role in preventing electronic devices from succumbing to the relentless heat generated during operation.

The Fusion of Tungsten and Copper:

Tungsten, renowned for its high melting point and exceptional durability, teams up with copper, a thermal conductivity maestro. The resulting tungsten copper composite strikes a harmonious balance, offering a unique blend of qualities that make it a preferred choice for heat sink applications. The collaboration of tungsten's strength and copper's efficient heat conduction creates a synergistic material designed to tackle the most demanding thermal challenges.

Efficient Heat Dissipation:

Tungsten copper heat sinks excel in efficiently dissipating heat generated by high-performance electronic components. Their ability to conduct and transfer heat away from sensitive areas ensures that devices operate within optimal temperature ranges. This becomes particularly crucial in power amplifiers, high-power laser systems, and other applications where heat management is paramount to sustained functionality.

Applications Across Industries:

The versatility of CuW heat sinks extends across a spectrum of industries. From aerospace to telecommunications, these heat sinks find applications in electronic devices, satellite components, and advanced laser technologies. Their robust thermal performance allows them to thrive in environments where conventional materials fall short.

Reliability and Longevity:

One of the standout features of CuW heat sinks is their durability and longevity. The composite material resists wear and tear, ensuring prolonged reliability even in harsh operating conditions. This makes them an invaluable asset for mission-critical systems where downtime is not an option.

Conclusion:

CuW heat sinks stand at the forefront of thermal management solutions, silently ensuring the efficiency and reliability of electronic devices. As the electronics landscape continues to evolve, these composite marvels will remain a beacon of innovation, guiding the way to a future where heat is harnessed rather than feared.

Chinatungsten Online is a professional manufacturer of tungsten and molybdenum for nearly thirty years. We can supply tungsten copper heat sink materials as per the drawings. Please free feel to contact us when you got the purchasing plans.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com