Precautions for Tungsten Wire in Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:38

- Written by Zhenghua

- Hits: 181

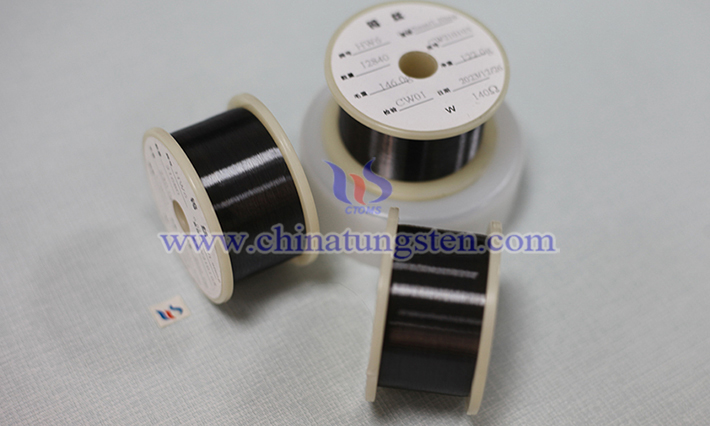

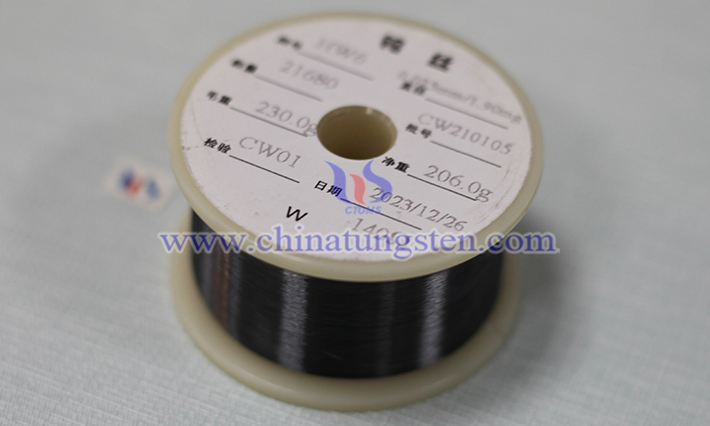

Tungsten wire, as a high melting point and high temperature resistant material, is often used in glass heating processes such as glass melting, forming or annealing. However, when using tungsten wire for glass heating, you need to understand the following precautions to ensure safety, efficiency and extend the life of the equipment.

1. Prevent Oxidation: Tungsten wire is very easy to react with oxygen at high temperature to form tungsten oxide, resulting in embrittlement or fracture. Therefore, the heating process needs to be carried out in a vacuum or inert gas (such as nitrogen, argon) protection environment, and the oxygen content is strictly controlled. Check the sealing before use to ensure that there is no leakage.

2. Temperature Control: The working temperature of tungsten wire is usually as high as 2000℃ or above, but too high temperature will accelerate the volatilization of tungsten wire and shorten its service life. It is necessary to accurately control the current and voltage, and cooperate with the temperature control system to avoid excessive temperature or excessive fluctuations. At the same time, gradually increase or decrease the temperature to prevent thermal shock from causing tungsten wire breakage.

3. Clean Environment: The surface of the tungsten wire needs to be kept clean and free of oil, dust or glass volatiles. These impurities may cause local high temperature or corrosion, affecting heating uniformity. Regularly check and clean the heating chamber to ensure that there is no contaminant deposition.

4. Mechanical Stability: Tungsten wire strength decreases at high temperatures and is prone to deformation or sagging. When installing, ensure proper tension and use a high-temperature resistant support structure (such as ceramic or molybdenum fixture) to fix it to avoid vibration or displacement. Consider thermal expansion during design and reserve enough space.

5. Electrical Safety: The resistance of tungsten wire changes greatly with temperature, and the current may surge during startup. Suitable power supplies and protective devices, such as current limiters or fuses, should be selected to prevent circuit overload. Regularly check the terminals to ensure good contact and avoid arcing or local overheating.

6. Exhaust Gas Treatment: Glass heating may produce volatile gases, and ventilation or exhaust gas treatment systems must be equipped to prevent the accumulation of harmful substances and ensure the safety of operators.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com