Safety of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:37

- Written by Zhenghua

- Hits: 186

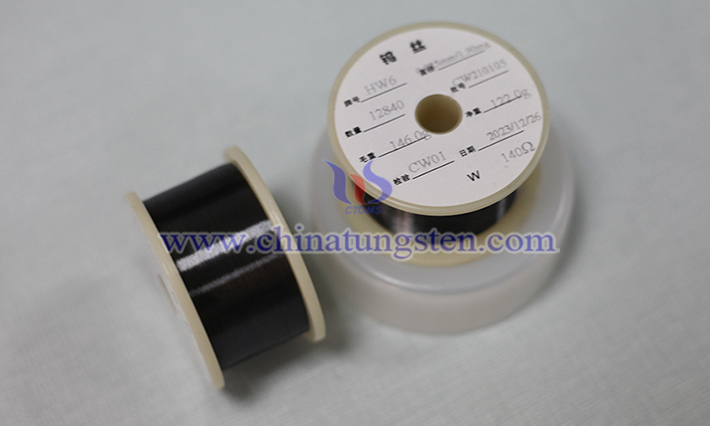

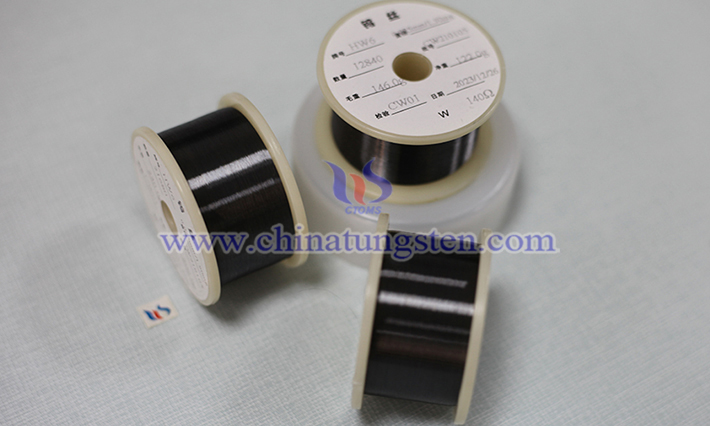

Tungsten wire is safe to use as a heating element in glass heating, but the premise is that the use environment is controlled (vacuum or inert atmosphere), the equipment is well maintained, the operation is standardized, and appropriate protective measures are provided.

1. High temperature safety: Tungsten wire has an extremely high melting point and is suitable for high temperature processes such as glass melting or molding. However, its operating temperature is often far higher than the softening point of glass (about 500-1500°C, depending on the type of glass), and it needs to be adjusted by a precise temperature control system (such as thermocouples and PID controllers) to avoid overheating, deformation or cracking of the glass and ensure process stability.

2. Oxidation problem: Tungsten wire is easy to react with oxygen at high temperature to form tungsten oxide, resulting in wire loss or failure. To ensure safety, it is necessary to operate in a vacuum or inert gas (such as argon, nitrogen) environment to prevent oxidation reactions, and regularly check the integrity of the sealing system.

3. Electrical safety: Tungsten wire, as a resistance heating element, requires a high current power supply. The circuit must be well insulated to prevent leakage or short circuit. Equipped with overload protection, fuses and temperature control devices can effectively prevent equipment from overheating and causing fire, ensuring the safety of operators and equipment.

4. Mechanical stability: Tungsten wire may deform or become brittle at high temperatures, and it is easy to break after long-term use. It is necessary to check its structural integrity regularly, replace aging wire materials in time, ensure mechanical stability, and prevent fragments from falling and causing equipment failure or safety accidents.

5. Radiation and protection: High-temperature heating of tungsten wire produces strong infrared radiation, which may cause burns or visual damage to operators. Protective glasses and high-temperature resistant gloves must be worn, and radiation shielding devices must be set up to reduce the risk of radiation exposure.

6. Environment and operating specifications: During the glass heating process, it is necessary to ensure that the working area is well ventilated to avoid the accumulation of harmful gases. Operators should receive professional training and be familiar with equipment operating procedures and emergency treatment measures to deal with emergencies, such as equipment failure or tungsten wire breakage.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com