Advantages of Tungsten Wire in Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:20

- Written by Zhenghua

- Hits: 184

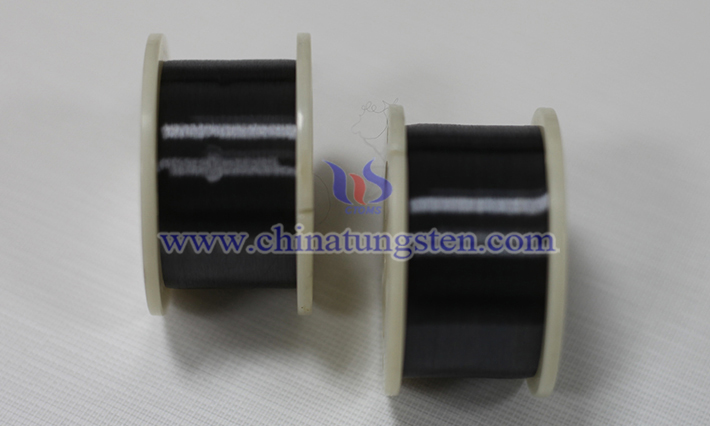

As a high-performance heating material, tungsten wire shows excellent advantages in the heating process of glass processing. Its unique physical and chemical properties make it an ideal choice for high-temperature processes such as glass melting, forming, and annealing. The following is an introduction to the application advantages of tungsten wire in glass heating:

1. High Melting Point and High Temperature Resistance

Tungsten has a melting point of up to 3422℃, making it one of the materials with the highest melting points among known metals. This feature enables it to operate stably in the high temperature environment required for glass processing (usually over 1000℃) without melting or significant deformation. Whether it is the continuous high temperature in the glass melting furnace or the instantaneous high heat during the glass drawing process, tungsten wire can easily cope with it to ensure the continuity and stability of the process.

2. Excellent Oxidation Resistance

In a vacuum or inert gas (such as argon, nitrogen) protection environment, tungsten wire can effectively resist high-temperature oxidation and significantly extend its service life. Glass heating equipment usually adopts sealed or controlled atmosphere design. The anti-oxidation property of tungsten wire makes it an ideal heating element, reducing material loss and equipment maintenance costs caused by oxidation.

3. Efficient Thermal Conductivity and Uniform Heating

Tungsten wire has high thermal conductivity and can quickly convert electrical energy into thermal energy and transfer it evenly to the glass material. This efficient thermal conductivity ensures uniform temperature distribution of the glass during heating, avoiding local overheating or cold spots, thereby improving the quality and consistency of glass products. Especially in precision glass molding or optical glass manufacturing, the uniform heating ability of tungsten wire is particularly critical.

4. Mechanical Strength and Stability at High Temperature

Tungsten wire can still maintain excellent mechanical strength and structural stability in high temperature environment, and is not prone to deformation, fracture or creep. This feature ensures the long-term reliability of the heating element and reduces production interruptions caused by material failure. In addition, the low thermal expansion coefficient of tungsten wire enables it to maintain dimensional stability in repeated heating and cooling cycles, which is suitable for complex thermal cycle conditions in glass processing.

5. Fast Thermal Response and Precise Temperature Control

The resistance heating characteristics of tungsten wire give it an extremely fast thermal response speed, which can reach the target temperature in a short time and achieve precise temperature control through current regulation. This fast response capability is particularly suitable for glass processing processes that require frequent temperature adjustments, such as glass blowing or wire drawing. Precise temperature control not only improves production efficiency, but also reduces energy consumption and scrap rate.

6. Excellent Corrosion Resistance

During the glass processing process, tungsten wire shows good corrosion resistance to glass melt and its volatile chemicals. Compared with other metal materials, tungsten wire is not easy to react chemically with glass components, avoiding the risk of contaminating glass products. At the same time, its corrosion resistance also reduces the wear of heating elements and reduces the frequency of equipment maintenance and replacement.

7. Flexible Application and Economic Benefits

Tungsten wire can be processed into different shapes and specifications according to process requirements, such as spiral, straight or mesh, to meet the design requirements of various glass heating equipment. In addition, although tungsten material itself is relatively expensive, its long life, high efficiency and low maintenance requirements make it have significant economic benefits in long-term use, especially in the production of high-precision, high-value-added glass products.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com