Advantages and Disadvantages of Cut-Resistant Tungsten Wire Protective Gloves

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 April 2025 19:08

- Written by Zhenghua

- Hits: 252

Cut-resistant tungsten wire protective gloves are specially designed protective gloves, usually used in scenarios that require high-strength cut resistance, such as industrial processing, glass manufacturing or metal cutting. The following is an analysis of its advantages and disadvantages:

I. Advantages of Cut-Resistant Tungsten Wire Protective Gloves

1. Exceptional Cut Resistance

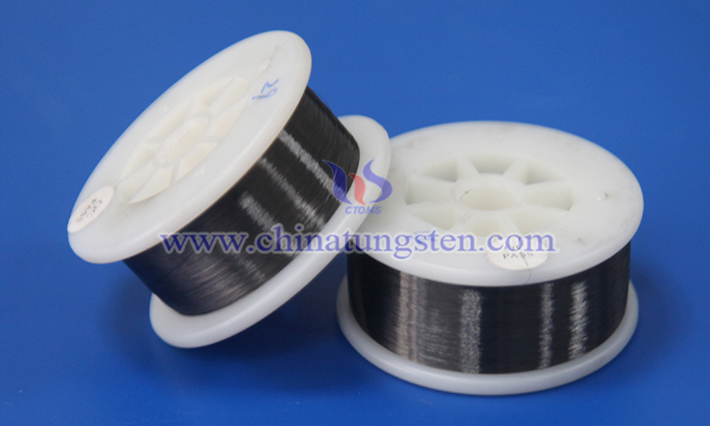

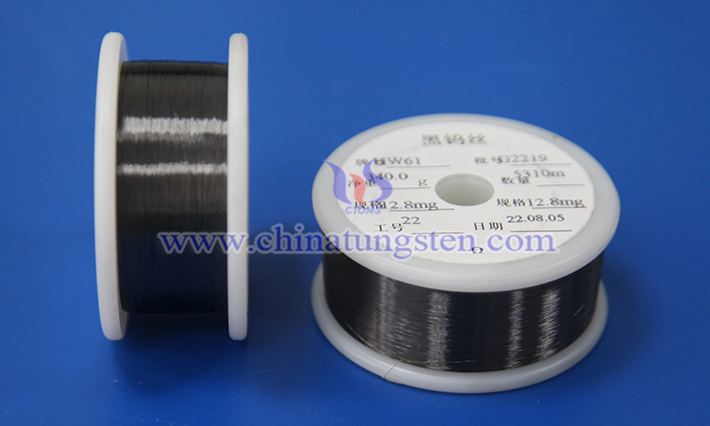

Tungsten wire (tungsten metal) has extremely high hardness and wear resistance. The gloves made can effectively resist damage from knives, sharp edges or high-speed cutting tools, and are suitable for high-risk working environments.

2. High Temperature Resistance

Tungsten has an extremely high melting point (about 3422°C), so this type of gloves can usually withstand high temperatures and are suitable for use in welding or high-temperature processing environments.

3. Strong Durability

Tungsten wire is tough, not easy to wear or break, and has a longer service life than ordinary fiber (such as Kevlar or fiberglass) gloves.

4. Comprehensive Protection

In addition to anti-cutting, it may also have certain anti-puncture and anti-wear capabilities, providing more comprehensive hand protection.

II. Disadvantages of Cut-Resistant Tungsten Wire Protective Gloves

1. Insufficient Flexibility

Due to the high rigidity of tungsten wire, this type of gloves may not be soft enough, affecting the flexibility of fingers and the fineness of operation, and is not suitable for work that requires high sensitivity.

2. Heavy Weight

Compared with traditional fiber materials (such as HPPE or aramid), tungsten wire gloves may be heavier, and long-term wearing may cause hand fatigue.

3. High Cost

Tungsten is a rare metal and difficult to process, which makes this type of gloves expensive and not suitable for large-scale popularization or low-budget use scenarios.

4. Poor Breathability

Tungsten wire materials usually do not have good breathability, and long-term wearing may cause sweating or discomfort in the hands.

5. Specific Use Limitations

Although they perform well in anti-cutting and high temperature resistance, for other needs such as chemical protection or waterproofing, these gloves may perform mediocrely and have relatively single functions.

In summary, cut-resistant tungsten wire protective gloves are suitable for high-risk, high-intensity specific working environments (such as metal processing or high-temperature cutting). Their protective performance and durability are highlights. However, they are limited in flexibility, comfort and cost, and the selection needs to be weighed according to the specific usage scenario. If you need more information about cut-resistant tungsten wire products, please contact China Tungsten Intelligent Manufacturing at sales@chinatungsten.com.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com