Tungsten carbide plane cutter planing Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 06 November 2014 18:31

- Written by xjq

- Hits: 502

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Can Cutting Fluid Be Used in Tungsten Carbide Cutting Tool

- Details

- Category: Tungsten Information

- Published on Thursday, 06 November 2014 18:29

- Written by xjq

- Hits: 564

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

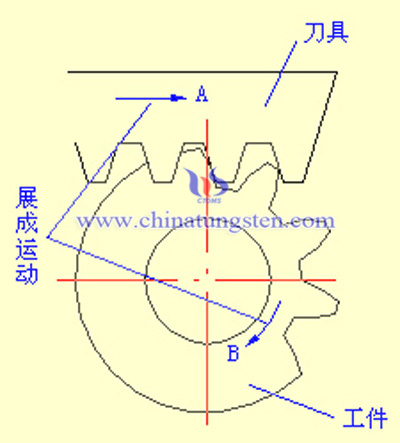

Tungsten Carbide Multithread Hobbing Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 November 2014 18:32

- Written by xjq

- Hits: 536

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Nail Sinker Advantages

- Details

- Category: Tungsten Information

- Published on Thursday, 06 November 2014 08:46

- Written by Sherry

- Hits: 498

Made of tungsten, tungsten nail sinker is designed specifically for the professional soft plastic bait angler to give anglers the extra edge against the competition.

And depending on where the tungsten nail sinker is inserted into the body of the soft plastic lure, the tournament angler is able to effectively tune the rolling action, diving pitch and buoyancy of the soft bait plastic lure to mimic an injured bait fish.

Tungsten nail sinker has the added benefit of being smaller than lead, thus reducing impedance of hook set. Tungsten nail sinker features barbs to help keep the sinker in place and ridges to prevent them from slipping out of the plastic. They can be took up in your tackle box, if consider carrying a few of these weights on hand, just given the limited space.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Cutting Tool Machining Methods

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 November 2014 18:27

- Written by xjq

- Hits: 521

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com