Tied Tungsten Drop Shot Weights

- Details

- Category: Tungsten Information

- Published on Monday, 17 November 2014 09:36

- Written by Sherry

- Hits: 502

These fine tied tungsten weights come with a drop shot clip swivel attached. Perfect for drop shotting, dropper looping, and down shotting your baits and lures for largemouth bass, smallmouth bass, spotted bass, or any other species of fish you are after. All tied tungsten drop shot weights come in a Natural Finish, and in the most popular size options. Tied tungsten drop shot weights are excellent for getting a feel of the bottom. Best yet, Chinatungsten tied tungsten drop shot weights cost less than any other commercially made brand.

Tied tungsten drop shot weights are designed with over 90% tungsten to nickel ratio; making them hard, dense, small, and lead free. There are all of the properties that you have come to love about tungsten but at a more affordable price. Tied tungsten drop shot weights are affordable enough for everyone to use.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Principles of Choosing Tungsten Carbide Turning Tool Rake angle

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 17:25

- Written by xjq

- Hits: 514

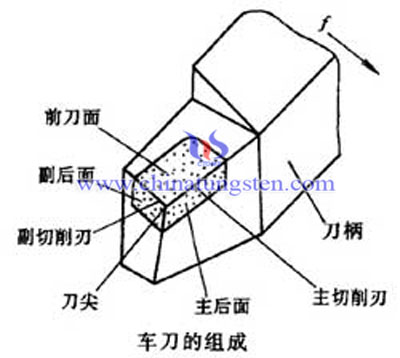

The intersection angle between the rake face and fundamental plane of tungsten carbide turning tool is called rake angle. It main function is to sharpen the cutting edge of turning tool, reduce cutting deformation, save cutting labor, and facilitate the chip removal. The size of rake angle can affect not only the cutting deformation and cutting force, but also the roughness of workpiece surface and the intensity and service life of cutting tools.

The principles of choosing the rake angle of tungsten carbide turning tool are as follows:

I. Choosing rake angle according to the workpiece materials. When the workpiece materials are relatively soft, larger rake angle should be adopted; when the materials are relatively hard, smaller rake angle should be adopted; when turning plastic materials, larger rake angle should be adopted; when turning hard brittle materials, smaller rake angle should be adopted.

II. Choosing rake angle according to the precision requirements of workpieces being processed. When rough turning towards workpieces with hard surface is conducted, smaller rake angle should be adopted; when finish turning is conducted, in order to improve the roughness of workpiece surface, larger rake angle should be adopted.

III. Choosing rake angle according to the material type of turning tool itself. When the turning tool material has poor intensity and toughness, smaller rake angle should be adopted but not vice versa.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Precautions of Using Tungsten Carbide Turning Tool with Indexable Inserts

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 17:21

- Written by xjq

- Hits: 558

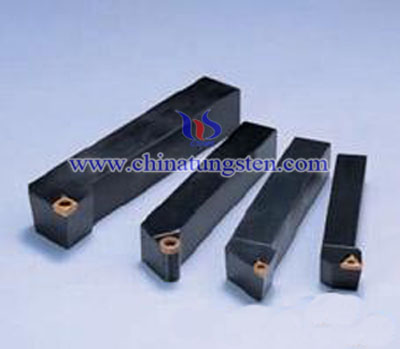

When using tungsten carbide turning tool with indexable inserts, operators should pay great attention to problems as follows:

I. Blade loosening

If blade loosening happens due to the vibration in the turning of tungsten carbide indexable inserts, operators should check whether the blade is clamped tightly or the clamping component is out of shape.

II. Abnormal noise

If there is squeak during the cutting, the reasons may be that the cutting tool is not clamped tightly; the cutting tool has seriously worn; the toolbar sticks out too far or lacks toughness; the workpiece for fixture lack toughness, and so on.

III. Spark in tool nose

If there is spark in the tool nose, the reasons may be that the cutting tool has seriously worn out; there is gap or blade tipping in the tool nose or cutting edge; the cutting speed is too high, and so on. Therefore, the cutting edge or blade then should be replaced and the cutting speed also should be adjusted.

IV. Blade surface stripping

If blade surface stripping happens during cutting, the amount of cutting fluid should be increased for those blade materials using cooling fluid, while for those high-hardness blade materials unsuitable to use cutting fluid, dry cutting should be adopted.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Advantages of Tungsten Carbide Indexable Insert for Turning

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 17:24

- Written by xjq

- Hits: 544

Tungsten carbide indexable insert for turning mainly adopts CVD coating technology to improve the bonding strength and reliability of coating. Its abrasion resistance and tipping resistance have been greatly improved compared with previous ones. The advantages of tungsten carbide indexable insert for turning mainly lie in the following aspects:

I. Improved abrasion resistance

In a practical application, the adhesive strength of tungsten carbide base body and its coating can be improved through thicker layer of close-grained Al2O3 even coating and the abrasion resistance can also be improved. Except that, the resistance property can be strengthened by increasing the proportion of AL in TiAlN coating.

II. Improved tipping resistance

To do strengthening and toughening towards the tungsten carbide base body surface can prevent tipping and damage of cutting edge.

III. Reduced bonding phenomenon

During the turning of SCM steel with soft quality and high toughness, the material bonding in cutting edge easily happens, which may cause the stripping of coating and the blade tipping. However, it can be prevented by adopting Ti compound.

IV. More sharped cutting edge

To prevent coating stripping in the cutting edge of tungsten carbide indexable insert, the cutting edge is generally made into R shape. The blade using in cutting small workpiece and grooves normally has a sharp cutting edge. Therefore, it would be better to keep the PVD coating thickness within 3μm.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable Inserts Precision Choosing

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 17:19

- Written by xjq

- Hits: 502

The national standard GB/T2076 – 1987 has stipulated twelve grades of precision towards tungsten carbide indexable inserts, which include A, F, C, H, E, G, J, K, L, M, N, u and so on.

G, M, u grades are normally adopted in turning machining, among which, G grade is of the highest precision, and M grade takes the second place, while U grade of the lowest precision. Obviously, during high precision machining, low precision blade can not be used, or it will affect the machining precision and quality of workpieces. Therefore, the precision of tungsten carbide indexable inserts should be chosen according to the precision requirements of the workpieces being processed. Principles below should be followed during the choosing.

I. Blades of G grade should be adopted during the finish machining and semi-finish machining of non ferrous metal materials and in the finish machining of quenched steel.

II. Blades of M grade should be adopted during finish, semi-finish, rough, and heavy cut machining except the two cases above.

III. Blades of u grade can also be adopted in the rough and heavy cut machining.

IV. The precision of indexable inserts used in automatic production lines should be higher than that in the common machining.

V. If there are tool setting gauges, it can be not so strict with the blade precision choosing.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com