Dendritic Crystal Form Bismuth Tungstate Preparation Scheme

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 November 2018 22:29

- Written by meiwei

- Hits: 484

Bismuth tungstate is a very important functional material in tungstate. It has been widely used in many fields, such as visible-light photocatalyst, water decomposition, hydrogen production, environmental purification and new energy development. It is well known that the properties of nanomaterials depend on the morphology and size of nanocrystals, so the preparation of bismuth tungstate nanocrystals with special morphology is of great significance in theoretical research and practical application.

Read more: Dendritic Crystal Form Bismuth Tungstate Preparation Scheme

Tungsten Trioxide Nano-Array Electrochrmic Thin Film Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 November 2018 22:11

- Written by meiwei

- Hits: 443

Electrochromic (EC) refers to the phenomenon that the optical properties of materials change reversibly under the action of an applied electric field. As an inorganic electrochromic material, tungsten trioxide (WO3) has been studied most fully. It has many advantages, such as pure color, stable chemical properties and strong adhesion to the substrate. However, traditional tungsten trioxide also has some disadvantages, such as slow transformation speed, low coloring efficiency, single color change and short cycle life.

Read more: Tungsten Trioxide Nano-Array Electrochrmic Thin Film Preparation

Tungsten Rhenium Removal by Ion Exchange

- Details

- Category: Tungsten Information

- Published on Monday, 05 November 2018 23:37

- Written by meiwei

- Hits: 2488

With the development and wide application of high performance tungsten materials, the influence of impurity element content on the properties of tungsten materials and tungsten alloys has been gradually recognized. The requirement of purity or some impurity content of ammonium paratungstate in various industrial fields will be higher and higher.

How to Choose Electrode Materials for EDM

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 November 2018 09:31

- Written by tang

- Hits: 682

How to choose the electrode material in EDM? Is it right to find tungsten-copper composites directly? First of all, we have to know what is the main electrode material of EDM to continue to deepen.

What are the main components of EDM electrode materials?

The electrode materials for electric discharge machining mainly include graphite, copper and tungsten-copper composite materials. I believe that the master of mechanical machining also knows that in EDM, the physical properties of the electrode material have a great influence on the discharge erosion amount, electrode loss, processing speed, machining accuracy and processing stability. Under different conditions, the use of different electrode materials will directly affect the processing quality. So, let us first understand the physical properties of the copper electrode, graphite electrode and tungsten-copper alloy electrode!

Physical properties of the copper electrode: Copper has a high corrosion resistance due to its large thermal conductivity and temperature coefficient. Therefore, the copper electrode is often used as an electrode material for processing small and medium-sized cavity mold parts, and its electrode loss is small.

Physical properties of graphite electrodes: Graphite has a high melting point and a high boiling point temperature, so its corrosion resistance is high. Moreover, the heat capacity of graphite is large, and it can adsorb free carbon during wide pulse roughing to compensate for the loss of the electrode, and the relative loss is low. Graphite also has the advantages of high consumption resistance, high temperature resistance, small deformation, light weight and high processing efficiency. However, graphite has a disadvantage in that the material is poor in rigidity and the sharp angle is easily broken.

Physical properties of tungsten copper alloy electrode: Tungsten copper composite with tungsten content of 50%~90% (mass fraction) combines many advantages of tungsten and copper, with high strength and hardness, good electrical and thermal conductivity, low The coefficient of thermal expansion, good resistance to arc erosion, high temperature oxidation resistance and fusion resistance. However, although tungsten copper is a preferred electrode material for metals, it is expensive and generally used for small precision machining. Tungsten copper is also resistant to wear, and it is easy to machine sharp angles. In fact, in the early days, researchers discovered that tungsten-copper composites have special advantages as EDM materials.

How to choose EDM electrode materials?

In EDM, proper selection of electrode materials is an important factor in ensuring processing quality and increasing productivity. At the same time, since the electrodes are processed differently during use, it is difficult to standardize the tool electrodes, and the difference in size or shape is large. Therefore, the following principles should be followed when selecting electrode materials:

1.0 On the basis of analyzing the technical characteristics of the workpiece and the technical requirements (surface roughness, size, tolerance accuracy), the electrode material should be selected according to the workpiece material and technical requirements.

2.0 First consider the choice of materials with good thermal conductivity and high melting point as electrode materials.

3.0 Take into account the factors such as easy electrode forming and good processing performance to obtain good EDM. Although the electrode materials used in EDM are mainly copper, graphite and tungsten-copper electrodes, due to some properties of the high-performance electrode itself such as purity, viscosity, structural compactness, uniformity and physicochemical properties, When it comes to different processing objects and different processing requirements, the selected electrodes and processing parameters are completely different.

After reading how to choose the electrode material, you must know that EDM is not directly looking for tungsten-copper composite material. Among them, there are many factors to consider, and the masters have to operate according to the actual situation.

In fact, the author wants to say that the application of tungsten-copper composites can be applied not only as an electrode for EDM, but also in high-end technologies such as defense military, aerospace, electronic packaging (CPU, etc.) and integrated circuits. For example, electromagnetic gun guide rail materials, rocket nozzle throat lining and gas rudder components, electronic packaging sheets, heat sink materials, and even vacuum switchgear, laser equipment, communication equipment, office equipment and sports equipment have their own appearance. Of course, the application of copper and graphite is certainly not just used as an electrode material, so I won't go into details here.

With the increasing precision of molds and the increasing use of many difficult-to-machine materials and the growing maturity of EDM processes, tungsten-copper composite EDM electrodes are becoming more common. Even so, in EDM, the electrode material is still reasonably selected because it is an important guarantee for ensuring the quality of the process. Therefore, an in-depth understanding of the performance of EDM electrode materials is a must for every technician engaged in EDM.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Ultrafine Tungsten Powder Preparation by Microwave Mechanical Ball Milling

- Details

- Category: Tungsten Information

- Published on Monday, 05 November 2018 23:22

- Written by meiwei

- Hits: 652

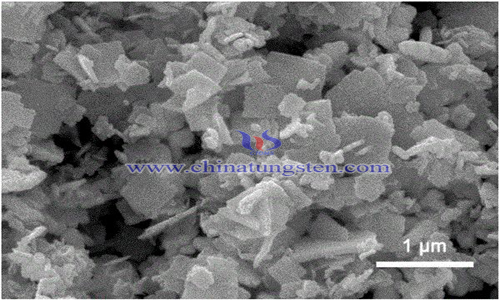

With the rapid development of microelectronics industry, energy, aviation, machinery industry and other fields, the demand for ultra-fine tungsten powder is expanding. The quality of ultra-fine tungsten powder directly affects the final performance of material products in various industries, so how to lower the cost, It is of great significance to efficiently produce high-quality ultra-fine tungsten powder for production and application research.

Read more: Ultrafine Tungsten Powder Preparation by Microwave Mechanical Ball Milling

sales@chinatungsten.com

sales@chinatungsten.com