WO3 Applied for O3 Gas Sensor

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 April 2020 17:39

- Written by Yahong

- Hits: 1649

WO3 is the optimal sensing material for producing O3 gas sensor by detecting changes in surface conductance after tungsten trioxide film on sensor contacts the measured gas - O3. As we all know, O3 has been widely used in disinfection and sterilization, sewage treatment and other aspects.

WO3 Applied for H2S Gas Sensor

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 April 2020 17:37

- Written by Yahong

- Hits: 1706

WO3, a n-type oxide semiconductor, is regarded as the best sensing material for fabrication of H2S gas sensor to realize the monitoring and detection of H2S gas. You know, H2S gas is an air pollutant, which not only seriously threatens human health, but also affects industrial production. In industry, the maximum allowable mass concentration of H2S in air is 0.01 mg/L. So, there is an urgent need to develop a H2S gas component.

WO3 Applied for NH3 Detection

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 April 2020 17:35

- Written by Yahong

- Hits: 1641

WO3 has excellent sensitivity and fast response speed to NH3 - colorless gas with strong pungent odor, so it is often made into a semiconducting gas sensor for NH3 detection. And therefore, WO3-based NH3 gas sensor has become one of the key research projects of scholars at home and abroad.

WO3 Thin Film Applied for NO2 Gas Sensor

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 April 2020 17:36

- Written by Yahong

- Hits: 1570

WO3 thin film is regarded as the best sensing material for the fabrication of sensitive and selective NO2 gas sensor. Some experts have fabricated NO2 gas sensor using WO3 thin films grown directly on to a soda-lime glass substrate without assistance of any seed layer by a simple and a facile hydrothermal technique.

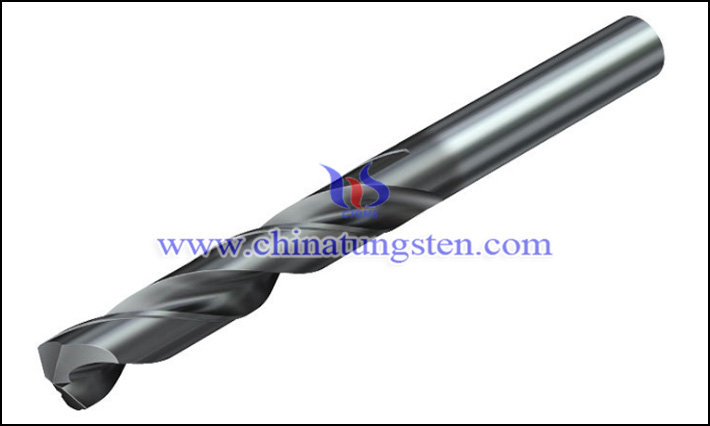

Solid Tungsten Carbide Drill

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 April 2020 17:13

- Written by Yahong

- Hits: 1647

Solid tungsten carbide drill has the characteristics of high efficiency, high accuracy, high degree of finish, high hardness, high strength, high wear resistance, bending resistance, breakage resistance, and long service life. And such a drill is easy to use, safe, reliable, economical and labor-saving. So, the tungsten carbide drill can reduce the processing cost of each hole while ensuring the drilling quality and drilling rate of the hole.

sales@chinatungsten.com

sales@chinatungsten.com