Production of Ammonium Metatungstate by Sodium Tungstate Transformation Method

- Details

- Category: Tungsten Information

- Published on Friday, 25 April 2025 16:42

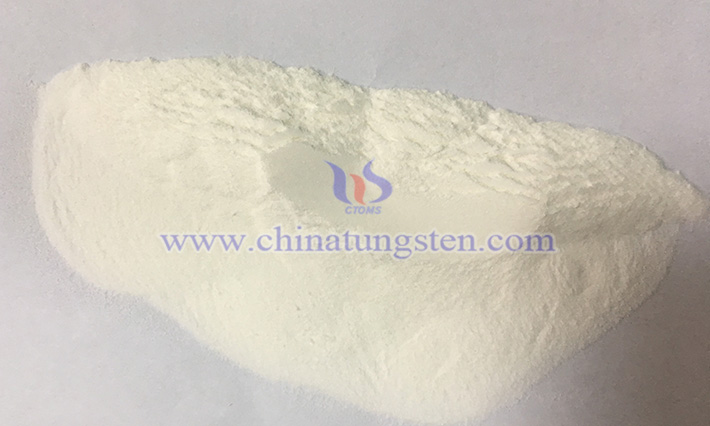

Ammonium metatungstate (AMT), a key tungsten chemical product, is widely applied in catalysis, petrochemicals, and new materials. The sodium tungstate transformation method is an important process for producing AMT, converting sodium tungstate into AMT through multiple chemical reactions and physical operations. This method is valued in industrial production for its low raw material costs and process flexibility.

Raw Materials and Requirements:

The raw materials for the sodium tungstate transformation method include sodium tungstate, calcium chloride, hydrochloric acid, and ammonia water, with each material’s quality directly affecting product quality and process stability. Sodium tungstate purity must be above 98%, with impurities (e.g., heavy metal ions, phosphorus, arsenic) strictly controlled. Calcium chloride, used as a precipitant, typically has a purity of at least 96%. Hydrochloric acid, used to dissolve calcium tungstate, has a concentration of 30%-36%. Ammonia water, used as a neutralizer, typically has a concentration of 20%-28%.

Process Steps of the Sodium Tungstate Transformation Method:

Calcium Tungstate Precipitation: Sodium tungstate solution is added to a reactor, and calcium chloride solution is slowly introduced under stirring. A double decomposition reaction occurs, forming insoluble calcium tungstate precipitate. Key controls: temperature at 40-60°C, calcium chloride dosage 5%-10% in excess, uniform stirring, followed by settling or centrifugation to separate the calcium tungstate filter cake.

Tungstic Acid Formation: The calcium tungstate filter cake is transferred to a reaction vessel, where hydrochloric acid is added to dissolve it, forming tungstic acid precipitate and calcium chloride solution. Key points: hydrochloric acid dosage 10%-20% in excess, continuous stirring, followed by washing.

Ammonium Tungstate Solution Preparation: The washed tungstic acid is added to a reactor, and ammonia water is slowly introduced to trigger a neutralization reaction, forming an ammonium tungstate solution. Key controls: temperature at 50-70°C, pH maintained at 8-9, and slow ammonia addition rate.

AMT Synthesis: An acid (e.g., nitric acid) is added to the ammonium tungstate solution to adjust the pH to 2-4, promoting the polymerization of tungstate ions into AMT. Key points: slow acid addition, continuous stirring, precise pH control, and temperature at 40-60°C.

Post-Processing Steps:

Evaporation and Concentration: The AMT solution is transferred to evaporation equipment and concentrated at 80-100°C under a vacuum of -0.08 to -0.06 MPa to remove excess water.

Cooling Crystallization: Gradient cooling is applied—first rapidly cooling to 40-50°C, then slowly to room temperature—to obtain uniform crystal sizes.

Filtration and Washing: Crystals are separated from the mother liquor using a centrifuge or filter press, then washed with deionized water to remove impurities.

Drying: Crystals are dried in a vacuum drying oven or hot air dryer at 80-120°C for several hours until the moisture content meets standards, yielding the final AMT product.

Advantages of the Sodium Tungstate Transformation Method:

Sodium tungstate is widely available and cost-effective, suitable for large-scale production.

Multiple reaction and separation steps effectively remove impurities, ensuring stable product quality.

Reaction conditions can be adjusted to produce AMT of different specifications based on demand.

Disadvantages:

Multiple reaction and separation steps extend the production cycle.

Evaporation and drying processes consume significant energy.

Corrosion-resistant equipment is required, leading to higher maintenance costs.

- Chinatungsten Online: ammonium-metatungstate.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com