Tungsten Carbide Cutting Tools Profile

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 09:36

- Written by yewq

- Hits: 490

With the development of industry, the use of increasingly difficult materials for processing efficiency requirements are also rising. Development of tungsten carbide cutting tools have a direct impact on improving productivity and processing quality. Material composition and structure as well as the geometry is to determine the performance of the three elements of tungsten carbide cutting tools, tungsten carbide cutting tools material properties which plays a key role.

tungsten carbide is a high hardness, refractory metal tungsten carbides (WC, TiC, etc.) micron-sized powder using Co, Mo, Ni, etc. as a binder and sintering of powder metallurgy products. Its high-temperature high-speed steel tungsten carbide content exceeds allowable cutting temperatures up to 800 ~ 1000 ℃, hardness at room temperature of 89 ~ 93HRA; at 540 ℃ when 82 ~ 87HRA, with the high-speed steel hardness at room temperature (83 ~ 86HRA) identical; 760 ℃ When the hardness of 77 ~ 85HRA, and has good chemical stability, heat resistance advantages. tungsten carbide cutting speed of up to 100 ~ 300m / min, far more than high-speed steel, high speed steel life is several times to several times. More than 90 percent in developed countries and more than 55 percent of the turning cutter tungsten carbide materials are used, the proportion of current use is still increasing. In addition, it is used to manufacture cemented tungsten carbide drills, milling cutters, gear cutters, reamers and other complex tools, tungsten carbide its excellent performance is more occasions alternative to other tool materials, has now become the main tool material one.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Silver Tungsten Alloy - Electrode Material

- Details

- Category: Tungsten Information

- Published on Thursday, 19 March 2015 08:45

- Written by Sherry

- Hits: 442

Electrode material must be good conductivity and has stable discharge characteristics. Copper electrode good processability, especially processing stability, less prone to arc discharge or the arc discharge transition, in most operations can stabilize the discharge, are widely used.

Graphite electrode machining stability is better, the most prominent feature is a large rough currents can remain stable discharge, and to ensure low loss electrodes, but in finishing, easy to discharge instability occurs, easy to pull arc burns. Silver-copper-tungsten alloys and tungsten electrode material is rarely used, because the price of expensive materials. They are still very stable micro-discharge machining parts, deep grooves and other difficult parts, electrode wear is extremely small, are considered for use in precision machining. Electrode material selection to ensure the quality of the discharge must be stable during processing. Copper copper must be free of impurities, the best hammered.

There are several graphite electrode material classification, such as Amy level, ultrafine grade, ultra-fine grade, fine grade, etc., according to the processing accuracy, efficiency requirements choice. Quality graphite material should be homogeneous, good strength, not easy to produce in the processing of flake. Using different electrode materials for processing should be flexible to deal with electrical pairing parameters in order to achieve stable discharge machining, machining works well, played the purpose of the selected material value.

Now many EDM electrical parameters can be automatically matched according to different combinations of materials processing. Mainly dealing with the electrical parameter pairing current, pulse width, pulse size of the gap. Performance electrode materials according to the appropriate choice of the electrical parameters of materials processing advantages to play, handle the processing of defects.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Tungsten Carbide Cutting Tools Surface Characteristics

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 10:18

- Written by yewq

- Hits: 463

Since the hardness and wear resistance of tungsten carbide cutting tools better, but poor toughness, can be obtained by the cemented tungsten carbide substrate, using CVD (chemical vapor deposition), PVD (physical vapor deposition), HVOF and other methods, a coating layer wear TiC, TiAlN, A12O3 and other thin layer (5 ~ 12μm), forming a surface coated tungsten carbide cutting tools, so that both high surface hardness and high wear resistance, but also tough matrix, can improve the tool life and processing efficiency.

Coated tungsten carbide cutting tools higher than the matrix hardness and wear resistance, high heat resistance (up to 800 ~ 1000 ℃). Such as hardness at normal temperature for HV2000, at 1000 ℃ still maintain HV1000, without coated tungsten carbide cutting tools fell to HV500. Coated tungsten carbide cutting tools than uncoated tungsten carbide high durability (generally 1 to 3 times increase, high up 5 to 10 times), high cutting speed, feed rate and cutting depth larger. These characteristics determine the coated tungsten carbide cutting tools especially for FMS, CIMS (Computer Integrated Manufacturing System) and other automated processing equipment. Coated tungsten carbide is one of the greatest achievements made in recent years in the field of tungsten carbide is another change cutting tool development.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

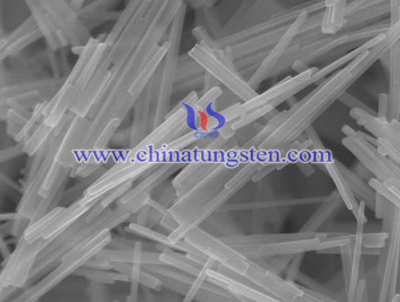

Tungsten Oxide Nanomaterials

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 18:31

- Written by zsq

- Hits: 409

Nano-sized materials and products have been used widely in many applications because of their outstanding properties, different from those of the bulk materials. In early investigations into nanotechnology, the arc discharge technique was the first well-developed method used to manufacture nanoproducts, whose growth mechanism was, in particular, the effects of catalysts and the atmospheres on the products were considered to be very important. However, owing to difficulties involved in controlling the manufacturing parameters, the purity and quality of nanoproductssynthesized by arc discharge called for improvement. The inert gas condensation (IGC) system was thus established. Because there are no catalysts or containments, it is considered the cleanest method of producing high-quality products. In this system,metals are first placed in a tungsten or graphite boat and evaporated. The metal vapor is then cooled under an inert gas atmosphereto condense into clusters or nanoparticles.

Although the arc method has a higher production rate than IGC system, the latter produces larger particles. Hence, a modified technique based on the IGC system was developed, in which blowing gases were introduced to obtain finer particles with better particle size distribution.Several evaporation techniques are available, including electrical heating, laser vaporization, arc discharge and plasma arc. For some refractory materials, plasma arc is a promising method owing to its relatively high energy as compared to other heating methods. The use of a nozzle made the plasma arc induced by a modified torch more constricted and concentrated than that induced by a conventional torch. The conventional and modified plasma arc torches. To retain the benefits of both thearc discharge method and the IGC system, a plasma arc is used as the heat source and blowing gas is applied to quench the evaporated materials in this modified system. A simplified manufacturing process that enhances the purity of the as-prepared products is required. Therefore, an effective method, namely, the modified plasma arc gas condensation technique has been proposed.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ultra-Fine Grain Tungsten Carbide Cutting Tools

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 March 2015 10:16

- Written by yewq

- Hits: 491

Ultra-fine grain tungsten carbide cutting tools has a high hardness and strength, tungsten carbide by the ultra-fine grain tungsten carbide cutting tools that is 0.5μm of WC, Co, vanadium tungsten carbide and chromium tungsten carbide Cr3C2 VC composition, suitable for In high-speed steel cutting tools wear enough, and as a result of vibrations caused by wear and tear or because the case is too low and should not use the traditional tungsten carbide cutting tools .

Ultra-fine grain tungsten carbide cutting tools WC grain size generally 0.2 ~ 1.0μm, 0.5μm or less at most, a fraction to a few tenths of an ordinary tungsten carbide WC grain size, and its hardness is generally 90 ~ 93HRA, flexural strength of 2000 ~ 3500MPa, the same ratio of cobalt content is generally high WC-Co cemented tungsten carbide cutting tools, and the work material attract each other - the smaller diffusion, especially for heat-resistant alloy, high strength alloy steel and other difficult materials. Fine grain tungsten carbide cutting tools previously used for K classes, but in the P class, ultra-fine tungsten carbide tungsten carbide M class, will be in the WC grains finer subgrain structure defects less comprehensive higher performance direction.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com