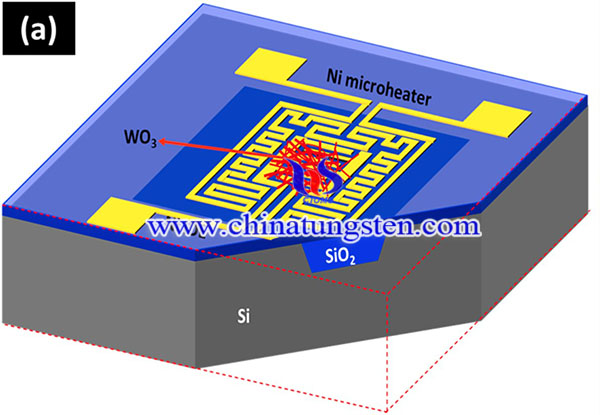

Synthesis Of WO3 Nanorods by Thermal Oxidation Technique for NO2 Gas Sensing

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 September 2021 13:12

With the development of industrialization, nitrogen dioxide (NO2) in automobile exhaust and industrial emissions is a serious threat to human health and the ecological environment. 0.1 ppm or even less NO2 will cause significant health effect to human health. Therefore, the highly sensitive NO2 gas sensor has attracted widespread attention. In various gas sensors, metal oxide semiconductor-based sensors are widely applied in industrial, medical and other fields. Due to the presence of several oxidation states of W, tungsten oxide (WO3) is a common sensing material for NO2 semiconductor sensors.

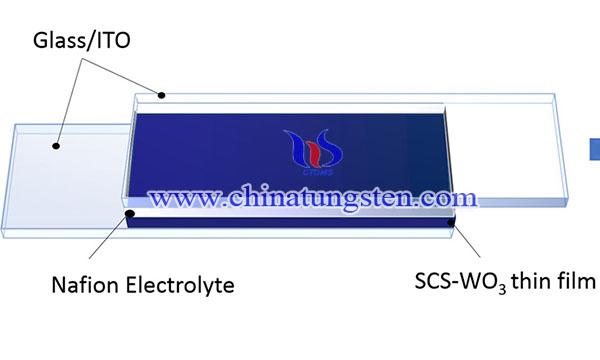

Smart Glass Electrochromic Device Prepared Based on Tungsten Oxide Films

- Details

- Category: Tungsten Information

- Published on Sunday, 05 September 2021 18:06

In the past few decades, electrochromic devices have received great attention from researchers in related fields in the materials industry. Electrochromism is a reversible change in optical properties (such as absorbance and transmittance) of a material under low electric fields. Electrochromic devices have a wide range of applications, including reflective displays, smart windows, information displays, and electrochromic paper.

Ammonium Metatungstate Applied in Low-Cost Electrocatalyst for Hydrogen Evolution

- Details

- Category: Tungsten Information

- Published on Sunday, 05 September 2021 17:42

Today, hydrogen is used in a variety of industrial applications. Initially, it was the basic material required in various chemical processes such as oil refining, the production of ammonia and methanol, and the synthesis of many polymers. In addition, hydrogen is also used in other industrial sectors, namely: glass and electronics production, metallurgy and food industry. Due to its characteristics, hydrogen is also considered to be one of the most important energy sources and can replace carbon-based fuels.

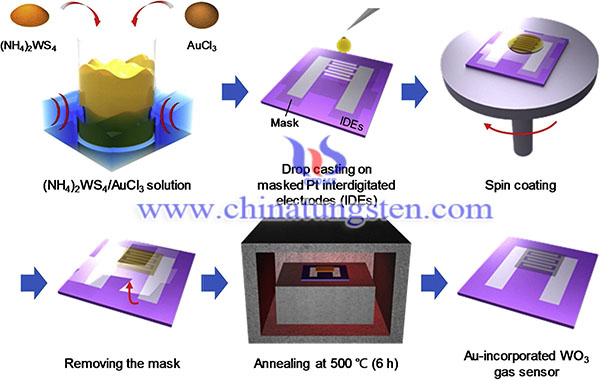

Au-Doped Tungsten Trioxide Thin Films for NO2 Sensing

- Details

- Category: Tungsten Information

- Published on Friday, 27 August 2021 16:49

The information provided is given as reference. The gas molecules of Nitrogen dioxide (NO2) are not benefit to the human, plant, and animals. The gas can cause various problems, such as negative effect to lungs, smog rain, and is mainly fashioned from the burning of fossil fuels inside the combustion engines, alongside the other forms of NOx, such as NO and N2O.

WO3 Films as Electrochromic Material for Smart Glass Applications

- Details

- Category: Tungsten Information

- Published on Friday, 27 August 2021 16:07

Electrochromic (EC) materials have received distinguished attention because of their potential applications in smart windows, displays, and antiglare rearview mirrors. More interestingly, the electrochromic smart windows are considered being able to provide indoor comfort and reduce energy consumption in buildings because it could exhibit an ability to regulate the amount of sunlight entering the buildings. To achieve the excellent energy-saving effect, electrochromic smart windows should be able to adjust to near-infrared light along with visible light due to its broad range in sunlight.

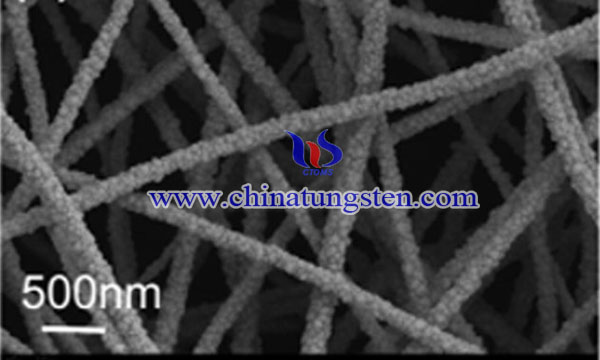

WO3-Based Composite Nanofibers with High Visible Light Photocatalytic Activity

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 22:33

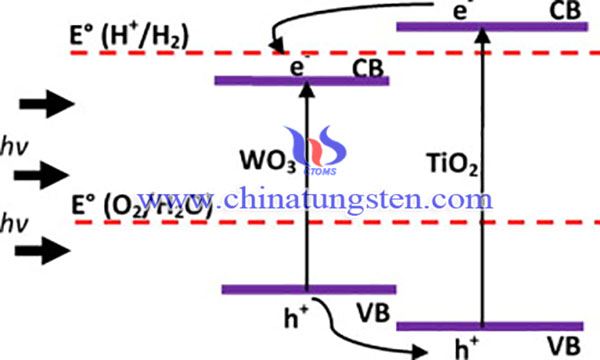

Photocatalysis is a great technology to treat wastewater with environmental protection, more straightforward operation, high mineralization rate, and strong oxidation ability to efficiently remove the low concentration of organic pollutants in water.Tungsten trioxide (WO3) is a promising candidate for photocatalyst owing to its narrow energy gap (2.4–2.8 eV), high oxidation potential (+3.1–3.2 VNHE) of the valence band (VB), which is further meritorious for inducing the performance under visible light. WO3 is a widely studied metal oxide semiconductor for many cutting-edge applications such as photo/electrocatalysis, energy storage, smart window, antibacterial, anticancer agents, and pathogens control. Zinc tungstate (ZnWO4) has a wide band gap (about 3.8–5.7 eV) and possesses matched band structures with WO3. The introduction of ZnWO4 not only significantly promotes electron-hole separation but also broadens the absorption edge of WO3 and increases light absorption. Moreover, the addition of noble metal silver (Ag) can improve visible-light photocatalytic efficiency due to the increase of electron-transfer between semiconductor and noble metal.

WO3-TiO2 Nanotubes Prepared Using Ammonium Paratungstate for PEC Water Splitting

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 16:57

Global energy demand, mainly based on unsustainable fossil fuels, has grown considerably during the last decades. Moreover, the emission of green house gases had caused environmental pollution and global warming.

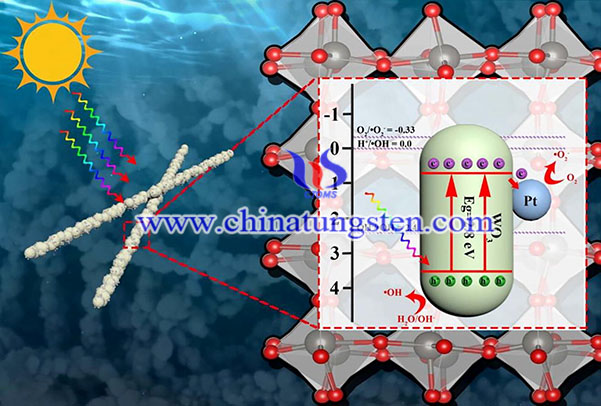

Ultrafine Pt-WO3 Nanofibers Synthesized via Ammonium Metatungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 16:40

Photocatalytic degradation has emerged as a promising technology for complete wastewater decontamination because of its organic and synthetic dormancy, essential limit, cost-viability, and long-haul security against chemical corrosion.

Ultrasensitive Gas Sensor Based on WO3-NiO Nanocomposites

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 01:58

Metal oxide semiconductor (MOS) materials have been widely applied for gas sensing and environmental protection, because of their wide availability and high sensitivity to low ppm concentration of gases.

High-Purity Tungsten Carbide Fabricate Using Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 01:39

Tungsten carbide (WC) has several excellent properties, including high melting point (2600–2850 °C), great hardness, high fracture toughness, high electrical and thermal conductivities, which make it become a promising material in various fields. Considering these excellent properties, WC has been widely used as cemented tungsten carbide materials in the tool industry to produce cutting, mining tools, drilling tools and general wear parts.

sales@chinatungsten.com

sales@chinatungsten.com