Tungsten Carbide Balls Polishing Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 19:04

The polishing process for tungsten carbide balls is mainly used to enhance their surface finish, dimensional accuracy, and sphericity. It is typically applied in fields such as precision bearings, valves, and instruments. The following provides a detailed explanation of the tungsten carbide ball polishing process, covering the main steps, methods, and precautions:

The Relationship between Hardness and Wear Resistance of Tungsten Carbide Balls

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:57

The hardness of tungsten carbide balls is a key determinant of wear resistance. High hardness generally results in excellent wear resistance, but a balance between hardness and toughness must be achieved by adjusting the composition, grain size, and binder phase ratio to suit different operating conditions. In practical applications, wear resistance is also affected by friction conditions, environment, and the mating material.

High-Temperature Performance of Tungsten Resin

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:48

Tungsten resin is a novel composite material whose high-temperature performance primarily depends on the type of resin matrix, the properties of tungsten powder, and the preparation process. Common resin matrices include polyethylene-based resins, epoxy resins, polyurethanes, and specialty resins.

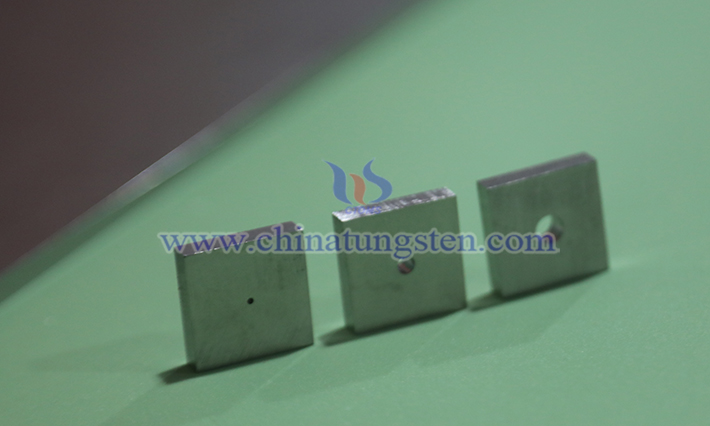

Applications of Tungsten Resin in Golf Clubs

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:45

Tungsten resin, due to its high density, excellent processability, and environmental friendliness, is widely applied in golf club manufacturing applications, primarily for counterweight components such as head weights or shaft weights to optimize the center of gravity, enhance swing stability, and improve ball-strike performance.

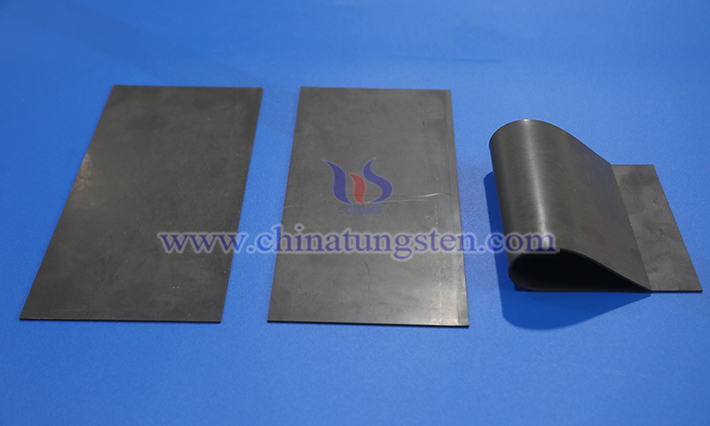

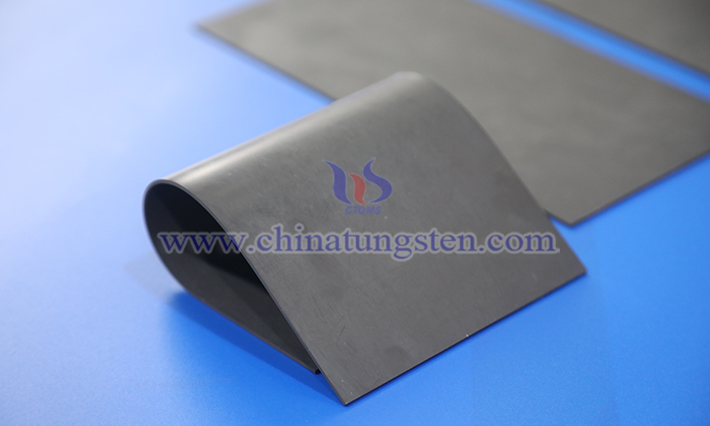

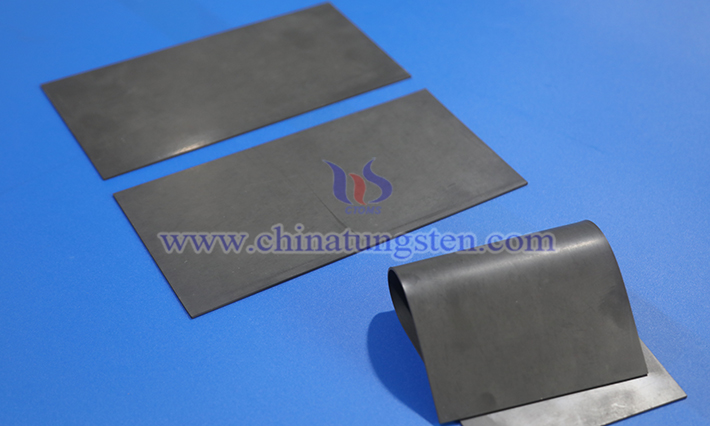

Preparation Methods of Tungsten Resin

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:43

CTIA GROUP LTD tungsten resin is a composite material made from tungsten powder and a resin matrix (such as polyethylene, epoxy resin, or other polymer materials), widely used in radiation shielding, fishing gear, and biomimetic materials. The preparation methods for tungsten resin vary depending on the matrix type, tungsten powder content, and application requirements, with common techniques including injection molding, compression molding, press-sintering, and high-speed mixing-calendering.

Magnetic Properties of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 15:16

Tungsten-nickel-iron alloy (W-Ni-Fe alloy), also known as high-density tungsten alloy, is a composite material with tungsten as the primary component and nickel and iron as binding phases. Typically containing over 90% tungsten, with the remainder a mixture of nickel and iron (e.g., typical ratios like 95W-3Ni-2Fe or 93W-5Ni-2Fe), this alloy is valued for its high density (16.5-18.5 g/cm³), high strength, corrosion resistance, and good machinability, finding wide use in defense, aerospace, medical, and industrial fields. The question raised by users concerns whether this alloy exhibits magnetic properties.

Application Advantages of Tungsten Alloy Collimators in Medical Field

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 14:50

Tungsten alloy collimators, primarily composed of tungsten with nickel, iron, and other elements, exhibit density characteristics surpassing those of collimators made from other materials, giving them a significant advantage in radiation shielding and wide application in the medical field. The application advantages of tungsten alloy collimators include strong radiation shielding capability, excellent radiation durability, environmental friendliness, and superior chemical stability.

What Is Tungsten Alloy Collimator?

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 14:44

Tungsten alloy collimator is a radiation control device designed using high-density tungsten alloy materials, with its core function being to limit the direction and range of radiation propagation through physical structures. It is widely used in medical, industrial, and scientific fields.

What Impact Does the Tungsten Prices Surge Have on the Industrial Chain?

- Details

- Category: Tungsten Information

- Published on Monday, 13 October 2025 19:07

The rise in tungsten prices has an uneven impact on various segments of the industrial chain, presenting a "smile curve":

How Much Influence Do Capital and Funding Have on Tungsten Price?

- Details

- Category: Tungsten Information

- Published on Monday, 13 October 2025 19:04

Capital and market sentiment have played a significant role in amplifying fluctuations in this round of price increases. Market data shows that capital has played a significant role in driving tungsten price increases. Price updates are quickly reflected within hours through share price fluctuations of related concept stocks in the secondary market.

sales@chinatungsten.com

sales@chinatungsten.com