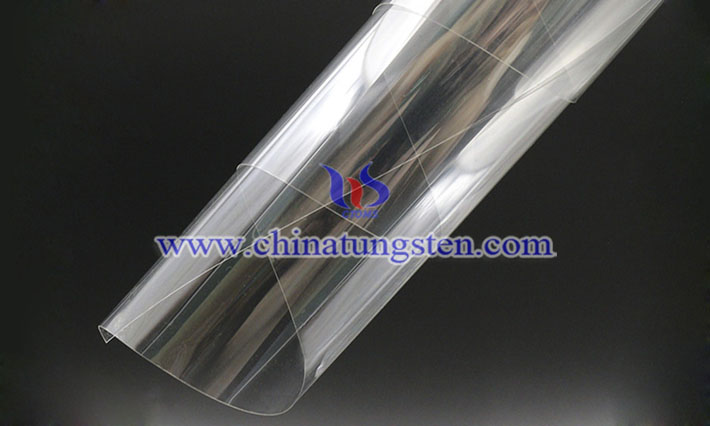

Doped WO3 Electrochromic Thin Film

- Details

- Category: Smart Glass

- Published on Monday, 16 September 2019 16:23

Doped WO3 electrochromic thin film can be prepared by the following steps: preparation of a stable sol and preparation of a WO3 film by using the stable sol which has been subjected to aging treatment as a precursor liquid.

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

Preparation of Stable Sol and Doped WO3 Electrochromic Film

Sodium tungstate and sodium molybdate were respectively disposed in a certain ratio to a standard aqueous solution with a concentration of 0.5M, and uniformly mixed to obtain a 250mL mixed solution. The mixed solution is slowly passed through a D072 type large pore size strong acid cation exchange resin, and acidified to obtain a mixed sol of tungstic acid and molybdic acid. After passing through the column, a certain amount of PEO, ethanol and acetone were added, and the mixture was stirred vigorously for 0.5h to obtain a PEO, MoO3 doped tungstic acid sol, and then standing. The PEO and MoO3 doped WO3 film layers were prepared by spin coating on conductive glass (ITO/glass) and conductive film (ITO/PET) using the sol after aging for 24 hours as the precursor solution. Wherein, conductive glass and conductive film should be ultrasonically washed in ethanol for 20 minutes beforehand, and then dried by hot air. After drying at 50°C, the sample is placed in a muffle furnace or vacuum drying oven where temperature can be precisely controlled for annealing heat treatment at each temperature.

Wherein, the heat treatment temperature of muffle furnace and vacuum drying oven is automatically measured and controlled by the thermocouple and the temperature controller. The temperature control precision is ±1°C, the heating rate is 10°C/min, the heat treatment atmosphere is air, and the time is 2h.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com