Tungsten Trioxide Nanometer Array Applied for Electrochromic Material

- Details

- Category: Smart Glass

- Published on Tuesday, 16 April 2019 16:10

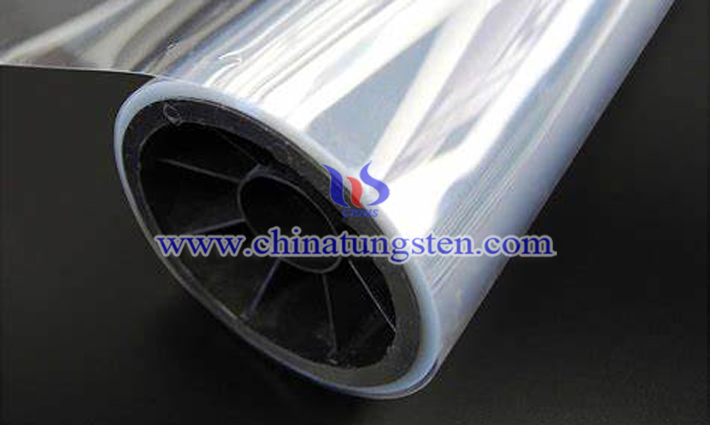

Tungsten trioxide nanometer array can be used to prepare electrochromic material, i.e., a transparent electrochromic film, which is typically used in electrochromic devices. It makes WO3 more and more concerned by the material industry. The following is a preparation method of tungsten trioxide nano array electrochromic film proposed by an expert, and the specific steps are as follows:

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

1.0 FTO conductive glass was ultrasonically cleaned with acetone, deionized water and ethanol for 10 minutes, and purged with nitrogen to obtain clean FTO conductive glass;

2.0 An excess of 10mol/L concentrated hydrochloric acid was dropped into a 1mol/L sodium tungstate aqueous solution until no new precipitate was formed, and the precipitate was washed with deionized water to obtain the milky white to pale yellow gelatinous precipitate - white tungsten acid. And it was dissolved in hydrogen peroxide aqueous solution of 30% mass of hydrogen peroxide. The molar ratio of white tungsten acid to hydrogen peroxide in aqueous hydrogen peroxide was 1:3. Add deionized water to prepare a tungstic acid solution containing tungsten with a concentration of 3mol/L, and chilling at 4°C for use;

3.0 The peroxy tungstic acid solution obtained in step 2.0 was spin-coated on the conductive surface of the clean FTO conductive glass at a speed of 3000r/min for 30s, and then placed in a box furnace at 300°C for 10 minutes. Repeated spin coating four times to obtain FTO conductive glass covered with a seed layer;

4.0 0.1g of tungsten hexacarbonyl was added to a solution of 70ml of absolute ethanol and stirred to obtain a precursor solution with a concentration of tungsten hexacarbonyl of 0.00392mol/L, and 20μL of 10mol/L hydrochloric acid was added;

5.0 Based on the FTO conductive glass covered with the seed layer in step 3.0, the substrate was vertically erected and fixed in the reaction chamber polytetrafluoroethylene inner tank, and then the precursor solution prepared by adding the hydrochloric acid prepared in step 4.0 was poured into the reaction kettle, the reaction kettle was thermostatically reacted in a 200°C drying oven for 12h. After the reaction was completed, it was taken out from the reaction vessel, cooled with tap water, then rinsed with deionized water, vacuum dried, and then heat treated at 400°C in a box furnace for 2h to obtain WO3 nano array electrochromic film.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com