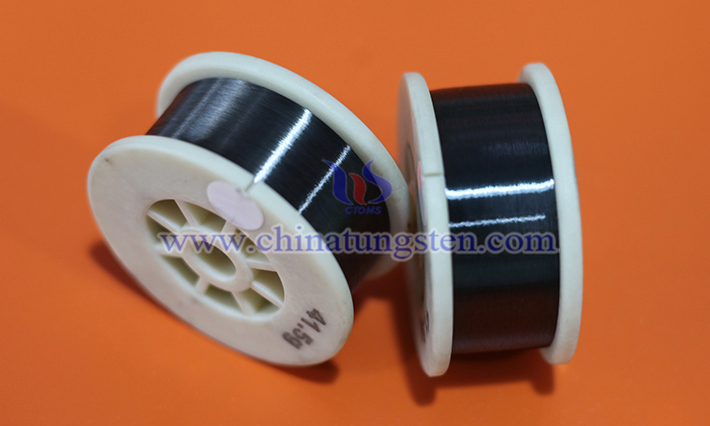

Applications of Tungsten Wire as Reinforcement in Composite Materials

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:17

The applications of tungsten wire as reinforcement in composite materials primarily stem from its unique physical and chemical properties, offering significant advantages in composite systems requiring high strength, heat resistance, corrosion resistance, or special electromagnetic properties. Below is an analysis of its specific application scenarios and advantages:

1. Aerospace Field

(1) Application Scenarios:

It is used in the manufacturing of rocket engine nozzles, spacecraft thermal protection systems, high-temperature structural components, etc. For instance, carbon fiber-reinforced tungsten-based composites (C/W) can withstand extreme high temperatures (>3000℃) and high-speed airflow erosion while maintaining structural integrity.

(2) Advantages:

Heat Resistance: Tungsten has a melting point of up to 3410℃, significantly higher than that of titanium alloys (1668℃) and nickel-based superalloys (around 1300℃), making it suitable for extreme thermal environments.

High Strength: The tensile strength of tungsten wire can reach 3000-5000 MPa, significantly enhancing the load-bearing capacity of composites.

Thermal Shock Resistance: The combination of tungsten and carbon fiber reduces cracking caused by thermal stress, extending material lifespan.

2. Nuclear Energy Industry

(1) Application Scenarios:

Nuclear reactor control rods, neutron shielding materials, etc. Tungsten wire-reinforced composites can withstand high radiation doses and high temperatures while maintaining structural stability.

(2) Advantages:

Radiation Resistance: Tungsten has a low neutron absorption cross-section and is less prone to swelling or embrittlement due to radiation.

Chemical Stability: In high-radiation and high-temperature environments, the interface between tungsten wire and the matrix (such as ceramics or metals) remains stable, preventing performance degradation.

3. Electronics and Semiconductor Industry

(1) Application Scenarios:

Vacuum Electronic Devices: Tungsten wire serves as a cathode emitter in X-ray tubes, electron microscopes, etc., with its high melting point preventing performance degradation due to thermal evaporation.

Packaging Materials: Tungsten wire-reinforced ceramic matrix composites (such as Al₂O₃/W) are used for packaging high-power electronic devices, improving heat dissipation and mechanical strength.

(2) Advantages:

High-Temperature Stability: It maintains low resistivity and stable emission performance at high temperatures.

Compatibility with Ceramics: Tungsten matches the thermal expansion coefficient of ceramics like alumina, reducing interfacial stress.

4. Automotive and Energy Fields

(1) Application Scenarios:

Gas Turbine Blades: Tungsten wire-reinforced nickel-based or cobalt-based superalloys enhance the high-temperature and fatigue resistance of blades.

Fuel Cells: Tungsten wire serves as a current collector in proton exchange membrane fuel cells (PEMFCs), improving conductivity and corrosion resistance.

(2) Advantages:

Creep Resistance: Tungsten wire inhibits creep deformation of the metal matrix at high temperatures.

Corrosion Resistance: In acidic or oxidative environments, a dense oxide film forms on the surface of tungsten wire, protecting the matrix.

5. Special Functional Composites

(1) Application Scenarios:

Electromagnetic Shielding Materials: Tungsten wire woven mesh embedded in a polymer matrix is used for high-frequency electromagnetic shielding (such as in 5G communication equipment).

Bulletproof Armor: Tungsten wire-reinforced ceramic composites (such as B₄C/W) combine high hardness and toughness to enhance impact resistance.

(2) Advantages:

Electromagnetic Properties: Tungsten's high density (19.3 g/cm³) effectively absorbs and reflects electromagnetic waves.

Dynamic Response: Under high-speed impact, the ductility of tungsten wire absorbs energy, reducing crack propagation.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com