EPFL Carves Nanopatterns into 2D Molybdenum Ditelluride Materials

- Details

- Category: Tungsten's News

- Published on Saturday, 04 July 2020 13:26

To carve nanopatterns into 2D molybdenum ditelluride materials, researchers at Ecole polytechnique fédérale de Lausanne (EPFL) have developed a high-precision technology. The new technology enables researchers to use microscalpels to break the links between atoms with a miniature scalpel. The team stated that it is extremely hard to structure materials using conventional lithography.

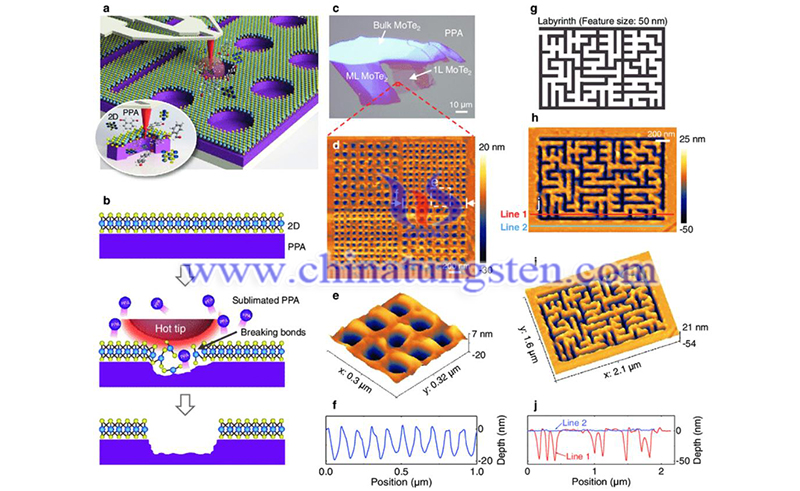

Traditional photolithography techniques use aggressive chemicals or charged particles such as accelerated electrons or ions. The problem is that these methods damage the properties of the material. The new technology uses local heat and pressure sources to accurately cut the material. The team described its technology as similar to the art of paper-cutting, but on a much smaller scale.

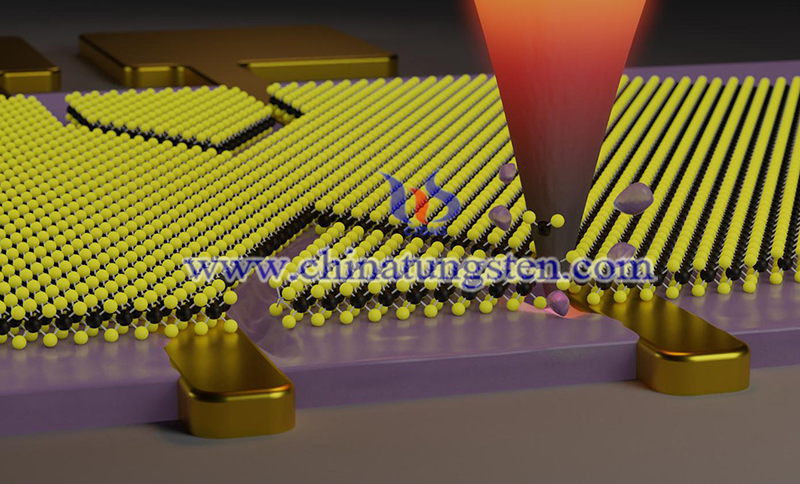

The EPFL technology to engrave nanopatterns uses thermal energy to modify the substrate to make it more flexible. In some cases, it can even be turned into a gas. After this process, two-dimensional materials can be more easily carved. In the study, the team used molybdenum ditelluride, a 2D material that is similar to graphene. The material is less than a nanometer thick.

Molybdenum ditelluride is placed on a polymer that reacts to temperature changes. When the polymer is heated, it will sublimate and change from solid to gas. The researchers heated a sharp, nano-sized tip above 180°C to bring it into contact with the two-dimensional material, and then applied a little force.

The computer-driven system controls the ultra-fast heating and cooling process and the position of the tip. The system allows researchers to make pre-defined indentations to create the nanostrips for nanoelectronic devices. Scientists say that the EPFL general technology to carve nanopatterns into 2D molybdenum ditelluride two-dimensional materials will play a role in nanoelectronics, nanophotonics, and nanobiotechnology, making electronic components smaller and more efficient.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com