How to Test for Real or Fake Gold

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 09:21

- Written by Cher

- Hits: 1572

Buying gold can be a great long-term investment, as long as you're buying real gold. Gold is a valuable commodity, which attracts people who wish to make some money through counterfeiting. The best way to determine whether your gold is fake is to go to a jewelry store and have it tested, however this may cost you some money. Alternatively, before you venture out to go buy gold, learn a few simple ways of determining whether the gold you're looking at is real or fake.

1.Put the magnet next to the gold. Real gold will not be attracted by the magnet, however fake gold or gold-plated metal will be attracted.

2.Rub the gold with a jewelry cleaning cloth. If the gold is fake, a few hard rubs will remove the plating.

3.Place the gold into sterling silver cleaning solution. After a day, real gold will not oxidize, however plated brass will.

4.Rub face powder onto your arm using a powder pad. Rub the gold against the powder on your skin. If it makes a black mark, it is real gold or gold-plated.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://paper-weight.cn/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Object to to Provide a Precision Bucking Bar

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 09:17

- Written by Cher

- Hits: 1269

It is thus an object to provide a precision bucking bar which will consistently spread a rivet to form a butt of uniform thickness, regardless of operator skill level, and which may be produced in traditional shapes and sizes to accommodate rivets in a variety of installations and to provide a “natural” feel to an experienced operator.

It is a further object of the present invention to provide squeeze points which will produce a properly shaped rivet butt of consistent thickness and shape regardless of operator skill level.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Precision Bucking Bar

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 08:54

- Written by Cher

- Hits: 1627

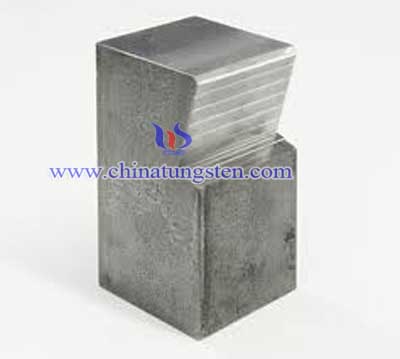

A precision bucking bar comprising a unitary rigid structure having a bucking surface thereon and a sidewall extending from the bucking surface such that, during a spreading operation, the bucking surface cannot contact the workpiece, thus producing a square butt of uniform thickness and a method for using the same. In another embodiment, the bucking surface is incorporated into a squeeze point for squeezers.

.A precision bucking bar for spreading a rivet through a workpiece comprising: a solid unitary structure having at least a first bucking surface thereon, said bucking surface having a first side wall, wherein said first side wall extends outwardly from said first bucking surface such that, when a rivet is spread, said first side wall will prevent said first bucking surface from contacting the workpiece.

A bucking bar is basically a metal anvil which is placed against the end of the shank of a rivet. Typically, a flat surface of the bucking bar interfaces a flat end of a rivet shank. The head of the rivet is then “hammered” by a driver, thereby causing the shank to spread against the bucking bar. To produce a properly shaped butt of proper thickness, prior art bucking bars have required a skilled operator. Failure of the operator to hold the bucking bar square against the rivet shank will result in misshaped butts and bad rivet resulting in costly rework. Furthermore, prior art bucking bars are prone to wandering during the spreading operation and occasionally wander off the shank, likewise resulting in a bad rivets and subsequent rework.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Precision Bucking Bar Devices

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 08:55

- Written by Cher

- Hits: 1776

Previous attempts have been made to develop a precision bucking bar which will produce a consistent butt regardless of operator skill. Such bucking devices suffer from a number of limitations. For example, they have universally required a relative large space behind the rivet, a luxury not available in many installations; they have not been available in a variety of geometries to avoid nearby obstacles; and they have not been of a conventional shape or size and thus have not felt familiar to an experienced operator. Hence, prior art precision bucking bars have not been well received in the field.

A second method for spreading a rivet employs an apparatus commonly known as “squeezes.” Squeezes typically include a pair of removable anvils, or points, a first point shaped to receive a rivet head, and a second provides a flat surface to interface the flat end of a rivet shank. To spread a rivet with a pair of squeezes, the rivet must be close enough to the edge of the workpiece for the squeezes to reach the rivet. The rivet is placed in a hole through multiple layers of sheet metal to be joined, the anvils are placed against each end of the rivet, and the operator squeezes the handle together to produce a compressive force between the head of the rivet and the end of the shank, thereby causing the rivet to spread. Automatic squeezes are also available wherein the points are pressed towards each other by a pneumatic or hydraulic actuator. As with driving a rivet, producing a quality butt requires the operator to maintain a consistently square angle between the face of the flat anvil and the rivet shank. Producing a consistent, quality butt requires an experienced operator.

Common to either type of spreading operation, a properly shaped butt of consistent thickness is essential to achieving maximum strength of the riveted joint. An improperly shaped butt may be too weak to hold under expected stresses or may concentrate stress in a small area resulting in failure of the workpiece.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Powder Typical Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 20:34

- Written by Yuri

- Hits: 1186

1) Machine tools

Tungsten carbide cutting surfaces are often used for machining through materials such as carbon or stainless steel, as well as in situations where other tools would wear away, such as high-quantity production runs. Most of the time, carbide will leave a better finish on the part, and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools. The material is usually called cemented carbide, hardmetal or tungsten-carbide cobalt: it is a metal matrix composite where tungsten carbide particles are the aggregate and metallic cobalt serves as the matrix.

2) Military

a) Tungsten carbide is often used in armor-piercing ammunition, especially where depleted uranium is not available or not politically acceptable. The first use of W2C projectiles occurred in German Luftwaffe tank-hunter squadrons, which used 37 mm autocannon equipped Junkers Ju 87G dive bomber aircraft to destroy Soviet T-34 tanks in World War II. Owing to the limited German reserves of tungsten, W2C material was reserved for making machine tools and small numbers of projectiles for the most elite combat pilots, like Hans-Ulrich Rudel. It is an effective penetrator due to its high hardness value combined with a very high density.

b) Tungsten carbide ammunition can be of the sabot type (a large arrow surrounded by a discarding push cylinder) or a subcaliber ammunition, where copper or other relatively soft material is used to encase the hard penetrating core, the two parts being separated only on impact. The latter is more common in small-caliber arms, while sabots are usually reserved for artillery use.

c) Tungsten carbide is also an effective neutron reflector and as such was used during early investigations into nuclear chain reactions, particularly for weapons. A criticality accident occurred at Los Alamos National Laboratory on 21 August 1945 when Harry K. Daghlian, Jr. accidentally dropped a tungsten carbide brick onto a plutonium sphere, causing the sub-critical mass to go critical with the reflected.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com