Tungsten Carbide Tool Hard Turning Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 April 2015 10:23

- Written by lucy

- Hits: 482

A main factor in the hard turning process of tungsten carbide tool is tool geometry or edge preparation.The edge preparation of the cutting tool (round or chamfered edge) affects the cutting forces, cutting temperature, and tool wear. According to Grzesik an extensive study characterizing the surface roughness generated during hard turning with conventional and wiper ceramic tools at a variable feed rate.

A similar study was also reported by Grzesik and Wanat. Their study investigated the surface roughness produced in the turning of hardened low-chromium alloy steel using mixed alumina–titanium carbon ceramic cutting tools equipped with both conventional and wiper inserts. Their results also demonstrated that wiper inserts working with a double feed rate showed similar wear behavior.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effecting Preparation of pyrochlore-type Tungsten oxides Factors

- Details

- Category: Tungsten Information

- Published on Monday, 13 April 2015 18:19

- Written by zsq

- Hits: 463

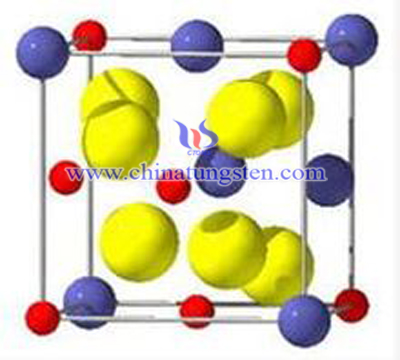

(1) Preparation of solution acidity pyrochlore-type oxides need not be confined to the desired acidic range, previous researchers summarized pH range (3.5 to 6.0) are not powder preparation must environment, the pH range that extends 3.5 ~ 8.9.

(2)Sodium tungstate solution pH or not cause a significant impact on the average particle size of the product; different additives can create a huge difference in the pH of the environment in the hydrothermal system, select the appropriate additives is to prepare pyrochlore The key factor of the tungsten oxide type.

(3) The size of the pH value of the reaction rate on the one hand will cause a major impact, pH smaller the faster the reaction rate; the other hand, the final solution will affect the decomposition rate, i.e. less than 7, the solution to generate complex tungsten-containing complex ions resulting solution structure changed dramatically, partly stable complex ions in solution are not easily transformed, resulting in W element can not be all entered H2W2O7 precipitate. From the simultaneous pursuit of the reaction rate, the decomposition rate of the final solution, the angle of view, the optimal conditions for the preparation of tungsten oxide pyrochlore type for pH≈7.

(4) Preparation of pyrochlore-type process, H + and reaction equivalent ratio WO42- 2 is more likely, according to the findings consistent element conservation law and the law of conservation of charge determined by the overall reaction scheme.

(5) Dosage and reactant solution temperature both will affect the reaction rate, the influence of can be summarized as follows: a solution at the same pH conditions, the reactants the higher the dose, the faster the reaction rate: the guaranteed reactants does not occur Under the premise of change, the higher the temperature, the faster the reaction rate.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tools with Aluminum Alloy Material

- Details

- Category: Tungsten Information

- Published on Monday, 13 April 2015 11:44

- Written by lucy

- Hits: 395

1.Free cutting aluminum alloy

The material is widely applied in the aerospace industry, the suitable tungsten carbide tools include K10, K20, PCD with the cutting speed varied from 2000 to 4000m / min. Its feed rate is 3 ~ 12m / min, rake angle is 12 ° ~ 18 °and after angle is about 10 ° ~ 18 °whereas the blade angle up to 25 °.

2.Cast aluminum alloy

According to the different Si contents in cast aluminum alloy , the tungsten tool selection is different.If the Si content is less than 12% of the cast aluminum alloy ,the suggestion tool is K10, Si3N4. If the Si content is more than 12%, it can be PKD (artificial diamond), PCD (polycrystalline diamond) and CVD diamond coated tools. For the over silicon aluminum alloy if si content is up to 16%~18% , the preferred one is PCD or CVD. Specially, for diamond coated tools, the cutting speed is around 1100m / min, while feed rate is 0.125mm / r.

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Temperature Effect Preparation Of Pyrochlore Type Tungsten Oxide Powder

- Details

- Category: Tungsten Information

- Published on Monday, 13 April 2015 18:18

- Written by zsq

- Hits: 492

Formulated a number of copies 0.3mol/L. Than the concentration of sodium tungstate solution of 100ml, and then divided into two groups do different treatment: one group solution R1 (OOH) n as an additive, the amount of each solution were added 2g, will stir mixed clarification Move solution autoclave, hydrothermal reaction at different temperatures within 24h 4h reaction time was analyzed for every solution. Another group of solutions chosen Ra (OH) n as an additive, in accordance with different doses of sodium tungstate was added to the solution, after the mixed solution was stirred into a uniform clear autoclave, subjected to hydrothermal reaction at different temperatures, only 24h after the solution was analyzed.

To R1(OOH)n is additive, the increase in the range of 110-140 ℃ temperature significantly help to improve response rates, reduce the temperature continues to increase the reaction rate Shique cause. From the microscopic point of view, the elevated temperature to increase the percentage of activated molecules, thereby increasing the chemical reaction rate. And because Rl (OOH) n prone to dehydration reaction itself at 160 ℃, thereby reducing the concentration of the solution in the expansion, causing excessively high temperatures but not conducive to promote the reaction.

With Ra (OH) n is additive, the effect of temperature on the decomposition rate after 24h, and added the effects of Ra (OH) n addition amount of the reaction rate. Visible increase Ra (OH) n addition amount of help to improve the reaction rate, which is consistent with the added Rl (OOH) n when the result. On the effect of temperature, the high temperature also increases the reaction rate and is not conducive to the final solution of the decomposition rate, since the Ra (OH). At about 180 ℃ into liquid, resulting in a significant increase in viscosity hydrothermal reaction is carried out to the detriment of, and at a high temperature prone to more complex self-decomposition reaction, reducing the concentration of weak acid product decreases the reaction rate.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool Coating Structure Classification

- Details

- Category: Tungsten Information

- Published on Thursday, 09 April 2015 14:28

- Written by lucy

- Hits: 445

Carbide tool coating structure classification can be divided into hard coated tool and soft coated tool,depending on the nature of the coating material. According to the different coating methods, the classifications include PVD and CVD.

(1) Single coating structure: also known as the conventional coating, the thin film is made into a particular compound or solid material.

(2) Multi-layer coating structure: adopting multi-layer methods, taking advantage of single-layer coating method and showing extra efforts in improving performance regarded to micro-hardness, high-temperature oxidation resistance and so on.

(3) Graded coating structure : successfully control the crack, gradually expanded its internal trends , while minimizing thermal stress , preventing the material from the surface to the base of cracks caused by failure of the expansion , improved defect carbide tools .

Tungsten Carbide Coating Tools: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com