China's Supply-Side Reforms Bring Silver Lining to Rare Metals Includes Tungsten

- Details

- Category: Tungsten's News

- Published on Thursday, 15 December 2016 10:31

- Hits: 600

To address excessive production, Beijing has been promoting supply-side reforms, which government-led moves are underway to consolidate producers, slash output and build up reserves. And while those efforts have struggled to make progress in the steel, coal and aluminum industries, they are gradually bearing fruit in the rare metals industry.

In April, China increased its reserves of tungsten, a rare metal used in carbide cutting tools, by 10,000 tons, or roughly 10% of the country's annual output. Prices of ammonium paratungstate, an intermediate material used as a stand-in for tungsten in pricing, had been holding below $200 per 10kg since last autumn, but they have since risen to around $210.

In March, China's eight major mining companies said that they were cutting production for the current year by 15% on the year. A trading house official said the companies have since agreed to raise the target to 20%.

Thanks to government-led stockpiling efforts, prices of rare-earth metals used in the manufacture of high-tech products have been climbing of late. The international spot price of neodymium, used in high-performance magnets, stands at about $56 per kilogram, while that of dysprosium is about $265 per kilogram. Both are up by 3% to 10% since May.

As for why supply-side reforms are working with rare metals but not for other commodities, compared with the industry's smaller size, steel, which makes it easier for the government to take control. Consolidation efforts, cooperative production cuts and increased reserves are supporting prices.

Demand trends are another actor. Demand for rare-earth metals is generally strong across the globe for use in high-performance motors for electric vehicles. For antimony, however, demand from Japan and Western economies for use in home appliances and for housing-related purposes is largely weak. Demand for the metal is also falling in China and other countries as electric bicycles switch from lead batteries to lead calcium batteries. Likewise, tungsten demand for carbide tools is declining due to stagnating mine development.

In the rare metals market, supply-side factors are sending prices higher. Whether the upward momentum continues, however, will likely depend on changes in demand.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Highest Performing Tungsten Disulfide Brings Flexible 2D Circuits Closer

- Details

- Category: Tungsten's News

- Published on Friday, 09 December 2016 10:31

- Hits: 886

Layered two-dimensional (2D) transition metal dichalcogenides (TMDs) — like tungsten disulfide or molybdenum disulfide — are attractive for electronics applications because you can manipulate their band gap simply by adjusting the number of layers used.

Solid Carbide Milling Tools Optimizes Machining of Stainless Materials

- Details

- Category: Tungsten's News

- Published on Wednesday, 07 December 2016 13:42

- Hits: 724

Being solid carbide milling tool increases tool life by up to 50% in austenitic stainless steels and nickel-base alloys. Tool operates best on machines having external coolant supply. Product uses asymmetrical helix angles between 35° and 38° which results in low susceptibility to vibration thereby increasing process reliability. Minimizing build-up on cutting edge, unit is coated with Titanium Aluminum Nitride which increases tool service life.

Some companies have introduced the solid carbide mill, positioned with the Advance product line designation. Advance referring to mid-level performance and price. Advance tools are one part of a group of solid tools labeled either Supreme (high-level performance and price), Advance (mid-level performance and price) or Perform (low-level performance and price). Which is a family of solid carbide milling tools that can increase tool life by up to 50 percent in austenitic stainless steels and nickel-base alloys.

The geometry has been designed to optimize the machining of stainless materials from the ISO M material group as well as for secondary applications in ISO S materials. The new tool family is engineered to operate most efficiently on machines having an external coolant supply.

A tough carbide substrate is used to provide superior machining reliability. In addition, process reliability is boosted by the mills’ low susceptibility to vibration by incorporating asymmetrical helix angles between 35° and 38°. The tools’ coating, a proprietary recipe of Titanium Aluminum Nitride designed and produced by Walter, increases tool service life and minimizes build-up on the cutting edge.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Short of Rhenium for Flight Engine Blade in China

- Details

- Category: Tungsten's News

- Published on Wednesday, 30 November 2016 16:03

- Hits: 936

The technology of flight research and development has caught up with developed countries, but there has been big problem for the short of raw materials, which are mainly in rare earth metals with high performances, such as rhenium.

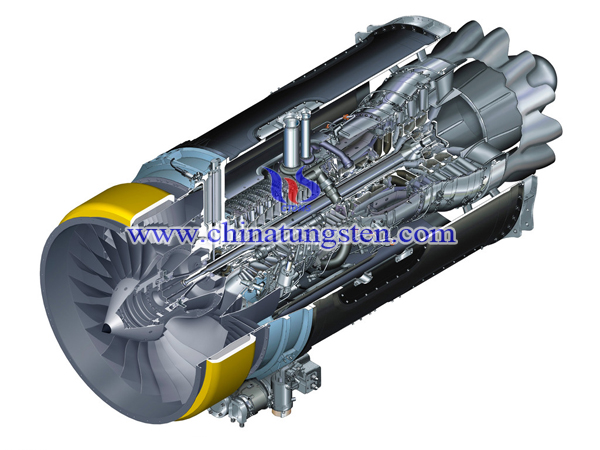

Rhenium is a metal with melting point of 3,180℃, similar to tungsten, which is 3,308℃.

Rhenium owns good physical and chemical performances, which results to a wide application in heat resistance parts in aerospace. One of the main use is as additive of 3% ~ 7% in flight engine Ni-based single crystal blade for its deformation and cracking resistance.

Engine Blade

Engine schematic

Engine 3D view

The reserve of rhenium all over the world is really rare with a whole quantity of proven quantity of 2,500tons and whole resource of 7,300~10,300 tons. But it is reported as only 237tons in China by Kunming Institute of Precious Metals.

Rhenium is significant and necessary metal in the development of flight engine, but its shortage has been some restriction for the research. Importing Re or finding alternative metals have been a new research for Chinese aerospace development.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

AH4 Ultra-light Howitzer’s Response Accuracy Superior Than American

- Details

- Category: Tungsten's News

- Published on Friday, 25 November 2016 21:56

- Hits: 2456

In the 11th Aerospace Expo held in Zhuhai on Nov. 1st, AH4 155 mm ultra-light howitzer was displayed in the indoor Weapons Museum.

Tungsten Oxide as Rewritable Material Helps Reduce Paper Waste

- Details

- Category: Tungsten's News

- Published on Friday, 25 November 2016 10:11

- Hits: 903

Even in today’s digital age, the world still relies on paper and ink, most of which ends up in landfills or recycling centers. To reduce this waste, scientists have now developed a low-cost, environmentally friendly way to create printed materials with rewritable paper, which is made out of tungsten oxide and a common polymer used in medicines and food.

The U.S. has been working to reduce paper waste by increasing recycling efforts for years. According to the Environmental Protection Agency, more paper is now recovered for recycling than almost all other materials combined. This saves energy, water, landfill space and greenhouse gas emissions. But even more waste could be avoided if consumers could reuse paper many times before recycling or trashing it. So far, however, such products under development often are made with toxic, expensive organic dyes.

The researchers created a film by mixing low-toxicity tungsten oxide with polyvinyl pyrrolidone. To "print" on it, they exposed the material to ultraviolet light for 30 seconds or more, and it changed from white to a deep blue. To make pictures or words, a stencil can be used so that only the exposed parts turn blue. To erase them, the material can simply sit in ambient conditions for a day or two. To speed up the erasing, the researchers added heat to make the color disappear in 30 minutes. Alternatively, adding a small amount of polyacrylonitrile to the material can make designs last for up to 10 days. Testing showed the material could be printed on and erased 40 times before the quality started to decline.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Electric Operated Tungsten Carbide Dental Drill Market

- Details

- Category: Tungsten's News

- Published on Wednesday, 23 November 2016 11:44

- Hits: 1026

Tungsten carbide dental drill is available in various designs. Tungsten carbide dental drill is basically composed of an air turbine, a hand-piece and tungsten carbide drill bit. Hand piece is a tube shaped slender connecting drill bit with the driving motor. Drill bit is the essential part of tungsten carbide dental drill. Tungsten carbide dental drills are constructed from a variety of raw materials such as metals and polymers. The most advance hand piece is made with titanium. Electric operated tungsten carbide dental drill generate large amount of heat. It performs cutting action smoothly. Tungsten carbide dental drill is frequently used by dentists and dental practitioners for treating cavities in diseases such as dental caries and abscesses, as to restore teeth. It bores through tooth enamel and removes or clean plaque from the surface of the tooth. After drilling the tooth completely, accurately and properly, it is prepared for filling with suitable material and crown to strengthen teeth. It also helps in reducing further damage. New innovations and technological advancement are replacing tungsten carbide dental drill with lasers. Nowadays, a new method known as air-abrasive technology is used by dentists of treating cavities. In this new method dentist blasts away parts of the tooth surface without using a drill.

Dentistry is defined as the evaluation, diagnosis, prevention, and/or treatment of diseases, disorders, and/or conditions of the oral cavity, maxillofacial area, and/or the adjacent and associated structures using surgical, nonsurgical, or related procedures. Concern for oral care is increasing due to rising prevalence of tooth decay, periodontal diseases, tooth erosion, and tooth sensitivity Dentists use various tools for different procedures such as removing cavity and cleaning teeth. These tools are made of metals such as stainless steel and tungsten carbide.

North America dominates the global market for electric operated tungsten carbide dental drill due to large number of aging population and increasing concern of oral hygiene. Asia is expected to show high growth rates in the next five years in the global electric operated tungsten carbide dental drill market. China and India are expected to be the fastest growing electric operated tungsten carbide dental drill markets in Asia-Pacific region. Some of the key driving forces for electric operated tungsten carbide dental drill market in emerging countries are large pool of patients, increasing healthcare expenditure and rising government funding.

In recent times there is increased use of electric operated tungsten carbide dental drill due to increasing incidence of dental disorders. Rise in aging population, increasing number of dental clinics and technological advancement are some of the key factors driving the growth for global electric operated tungsten carbide dental drill market. In addition, increasing healthcare awareness is also fuelling the growth of global electric operated tungsten carbide dental drill market. However, high cost of dental instruments, alternative technologies such as laser and brand loyalty are some of the major factors restraining the growth for the global electric operated tungsten carbide dental drill market.

Cosmetic dentistry would develop opportunity for global electric operated tungsten carbide dental drill market. However, lack of reimbursement for dental procedures could lead a challenge for the global electric operated tungsten carbide dental drill market.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

NMDC and MIDHANI Join Hands for Tungsten Mining

- Details

- Category: Tungsten's News

- Published on Thursday, 17 November 2016 18:04

- Hits: 1188

NMDC, one of India's biggest mineral producers, and Mishra Dhatu Nigam (MIDHANI) have signed a memorandum of understanding to develop tungsten minning and processing technology for the metal, a key ingredient in making heavy-alloy ammunition systems for the armed forces.

The two state-owned companies are slated to tap their complementary strengths to pursue a venture in developing tungsten mineral assets in India and abroad. MIDHANI, a defence sector PSU, has expertise in special metals and alloys. Availability of tungsten in India is limited and the metal is not mined because the ores are of low grade, NMDC said in a statement. The country's requirement of tungsten is met mainly through imports.

Extracting tungsten from low-grade deposits depends largely on developing suitable beneficiation technology. It is mainly Rajasthan that has tungsten reserves.

There is a growing requirement in India for tungsten products in industrial and defence applications, where it has been identified as a strategic material. The market for tungsten metal powder in the country is estimated at 150 tonnes per month.

China, world's largest producer of tungsten, accounts for over 80% of global output. Vietnam with 5,000 tonnes, Russia (2,500 tonnes), Canada (1,700 tonnes), Bolivia (1,200 tonnes) and Rwanda (1,000 tonnes) are the other major producers. Tungsten production globally rose to 87,000 tonnes in 2015 from 86,800 tonnes in 2014, according to the US Geological Survey.

With a strong mining background, NMDC has been working on to acquire mineral assets abroad. And Midhani, with its expertise in metals and alloys, is expected to provide technical support and coordination for Ammonium Paratungstate (APT). Their complementary strengths can facilitate in developing a venture for tungsten mineral assets in India and abroad. This alliance would strengthen both NMDC’s and Midhani’s resolve to explore jointly the available tungsten assets in India and consider investment and development abroad. The technology could also be used converting tungsten ore to APT and tungsten powder.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Effect of RMB Depreciation on Tungsten Products Exportation

- Details

- Category: Tungsten's News

- Published on Thursday, 17 November 2016 18:02

- Hits: 1092

As the exchange rate quotation showed on November 17, the central parity rate of the yuan against the U.S. dollar stood at 6.8700, a six-year low, and implied a depreciation of 10 percent over the past one year or so, considering the parity rate of 6.1162 on August 10, 2015.

Selection and Technical Application of Tungsten Carbide Drill

- Details

- Category: Tungsten's News

- Published on Tuesday, 15 November 2016 14:06

- Hits: 2469

Tungsten carbide drill is based on tungsten carbide powder, cobalt powder as binder by pressure, sintering. Usually containing tungsten carbide 94%, 6% cobalt. Because of its high hardness, very wear-resistant, have a certain strength, suitable for high-speed cutting. But poor toughness, very brittle, in order to improve the performance of cemented carbide, and some on the use of carbonized substrate in the chemical vapor deposition of a layer of 5 to 7 microns of special hard titanium carbide (TIC) or titanium nitride (TIN) Has a higher hardness. Some use ion implantation technology, the titanium, nitrogen, and carbon into the substrate a certain depth, not only improve the hardness and strength, but also in the drill regrind when the injection of these ingredients can move inward. There are physical methods used in the top of the drill bit to generate a layer of diamond film, greatly improving the hardness and wear resistance of the drill.

Selection of Tungsten Carbide Drill Material

According to the processing characteristics of the material, the requirements of the tungsten carbide drill has the following characteristics: the hardness of the drill must be greater than the hardness of the workpiece to be processed as the workpiece in the workpiece to withstand a great torsion and axial force, it must have sufficient strength and toughness; Due to the toughness of the material to be processed, the cutting edge is required to be sharp enough for cutting, so the tool material must have sufficient anti-wear ability, so as to reduce the work hardening; due to the chemical properties of the workpiece to be high, so the tool material and titanium alloy affinity difference , In order to avoid the travel caused by the proliferation of sticky knife, broken drilling phenomenon.

At present, the types of materials suitable for doing tool extremely wide, including tool steel, carbide, superhard materials.

At first, try to use ordinary high-speed steel drill bit for testing, ordinary high-speed steel drill bit low price, when using coating technology, can significantly reduce the friction coefficient of the tool and the workpiece to improve tool life. However, due to higher speed machine, the use of drill strength is not enough, resulting in the process of drilling bit broken, the effect is not satisfactory.

Tungsten carbide is the latest development of a tool material, suitable for most of the rough finishing of materials, including steel, cast iron, special materials and plastics. To this end, decided to use the tungsten carbide overall drill.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com