Principles of Choosing Tungsten Carbide Turning Tool Rake angle

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 17:25

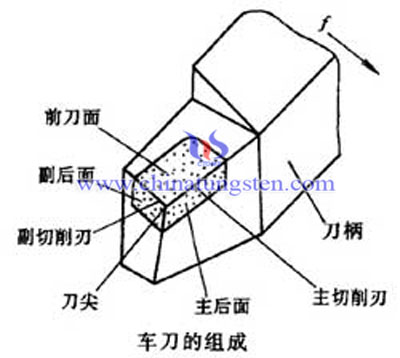

The intersection angle between the rake face and fundamental plane of tungsten carbide turning tool is called rake angle. It main function is to sharpen the cutting edge of turning tool, reduce cutting deformation, save cutting labor, and facilitate the chip removal. The size of rake angle can affect not only the cutting deformation and cutting force, but also the roughness of workpiece surface and the intensity and service life of cutting tools.

The principles of choosing the rake angle of tungsten carbide turning tool are as follows:

I. Choosing rake angle according to the workpiece materials. When the workpiece materials are relatively soft, larger rake angle should be adopted; when the materials are relatively hard, smaller rake angle should be adopted; when turning plastic materials, larger rake angle should be adopted; when turning hard brittle materials, smaller rake angle should be adopted.

II. Choosing rake angle according to the precision requirements of workpieces being processed. When rough turning towards workpieces with hard surface is conducted, smaller rake angle should be adopted; when finish turning is conducted, in order to improve the roughness of workpiece surface, larger rake angle should be adopted.

III. Choosing rake angle according to the material type of turning tool itself. When the turning tool material has poor intensity and toughness, smaller rake angle should be adopted but not vice versa.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com