Sol-Gel Synthesis of CeWTi Catalysts via Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 April 2021 06:13

The environmental issues and health effects by nitrogen oxides (NOx) had caught more attentions in the past decade. The main source of NOx resulting from human activities is the burning of fossil fuels (coal, gas and oil) especially gasoline used in cars. V2O5-WO3-TiO2 is the most common catalysts applied in industrial field for NOx reduction. Unfortunately, the toxicity of V2O5 limits the applications in some fields. Ce-based (Cerium) catalysts, which exhibit remarkable redox properties and high oxygen storage capacity, have attracted much attention in the NH3-SCR reaction.

In order to overcome the drawbacks, ammonium paratungstate (APT) had been utilized as raw material of tungsten trioxide (WO3) to modify cerium-based catalysts. low temperature SCR activities and sulfur resistance had been greatly improved.The CeWTi mixed oxide catalyst was prepared by a sol-gel synthesis method. The synthesis process is as below:

Cerium nitrate hexahydrate, ammonium paratungstate and commercial TiO2 powders were mixed in deionized water according to a mass ratio of CeO2: WO3: TiO2 = 5:5:90. And then citric acid and nitric acid were added. The solution was sufficiently stirred in a water bath and heated at 80 °C until a porous gel was formed. The gel was dried at 110 °C in an oven overnight. The resulting product was subsequently subjected to decomposition at 300 °C for 1 h and calcination at 600 °C for 3 h in a muffle. Finally, the samples were crushed and sieved to 40–60 mesh for catalytic activity measurements. The reference catalyst CeTi was prepared by the same method.The CeWTi and CeTi catalysts were sulfur aging separately in a pipe furnace. The sulfur aging proceeded at 400 °C with 100 ppm SO2, 10% water vapour, air balance for 48 h.

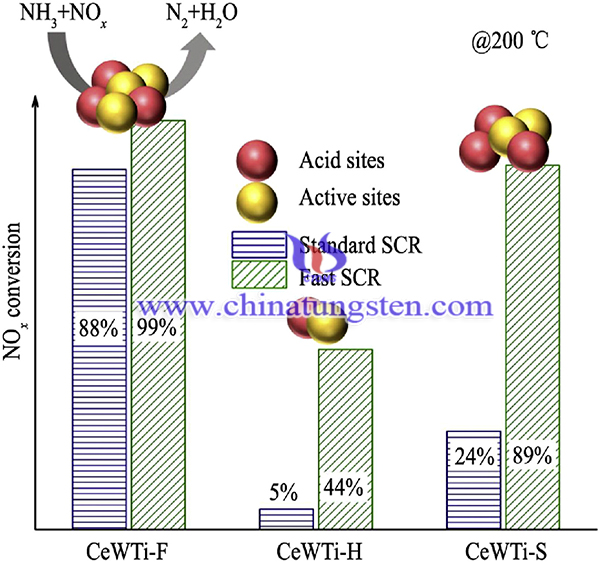

Compared with CeTi catalyst, the addition of tungsten inhibits the crystallization of catalyst when aging. More surface area and acidities left for aged CeWTi catalyst compared with that of aged CeTi catalyst. This is also the reason why tungsten addition improves the NH3-NO/NO2 SCR performance of CeTi catalyst.

In conclusion, the NH3-NO/NO2 SCR performances of sulfur aged catalysts are better than that of hydrothermal aged catalysts. Compared with CeTi catalyst, the addition of tungsten inhibits the crystallization of catalyst. So that more acid sites and active sites are retained. This is also the reason why tungsten addition improves the NH3-NO/NO2 SCR performance of CeTi catalyst.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com