Synthesis Method of Chromium-doped Ammonium Paratungstate Powder

- Details

- Category: Tungsten Information

- Published on Monday, 04 January 2021 21:37

It is known that preparation of tungsten carbide mainly consists of the following steps. Ammonium paratungstate (APT) is produced from ammonium tungstate solution through evaporation and crystallization, and then tungsten trioxide is produced by calcining APT, finally, tungsten carbide is prepared by hydrogen reduction and followed carbonization. Studies have showed a smaller particle size and uniform distribution of APT has a positive effect on the physical properties of tungsten carbide such as hardness, heat resistance, and wear resistance.

It is well known that addition of chromium into the solution effectively enhances nucleation of APT grains, which is favorable for the formation of fine APT grains. Many studies have shown that genetic relationship between grain size of ammonium paratungstate and tungsten powder as well as tungsten carbide is obvious.

The synthesis processes of can be concludes as below:

A certain volume of ammonium tungstate solution ([WO3] = 202.8 g/L, [NH4OH] = 96.6 g/L) was added into the reactor equipped with a temperature and stirring speed controller., and then a certain amount of (CH3COO)3Cr was added into the solution with Cr concentration of 0.4 wt.% (WO3-0.4Cr) under a temperature of 100 °C and a stirring speed of 50 rpm. After a specified amount of time, Cr-doped APT particles were precipitated from the solution and then filtered and dried. The Cr-doped APT powder was also used to prepare tungsten powder, tungsten carbide powder and WC-Co cemented carbide alloy in subsequent processes.

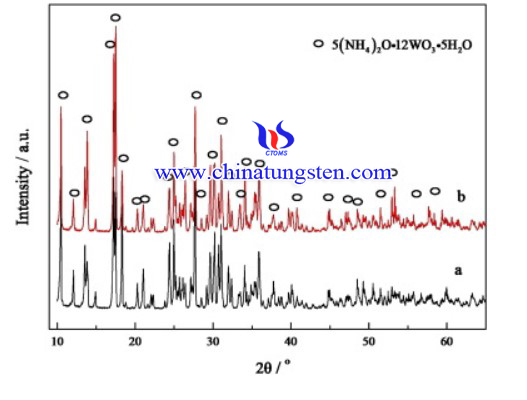

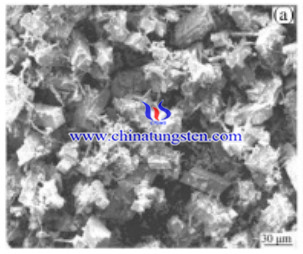

Structural characterization of the Cr-doped APT was performed by Infrared spectrograph. The microstructure of specimens was observed by a scanning electron microscope (JSM-6701F). XRD examinations were performed with the diffractometer (RigakuD/max 2500). Micro-area chemical analysis of specimens was conducted with X-ray energy dispersive spectrum (INCA). The average size of specimens was determined with a particle size analyzer.

In summary, the Cr-doped APT powder has been successfully produced with above process and it has a smaller grain size (29 μm) compared with the conventional APT powder (58.3 μm). A uniform particle size distribution of chromium has also been observed. These properties make the Cr-doped APT powder a excellent material to produce tungsten carbide alloys.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com