Application of Tungsten Disulfide in Automobiles

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 December 2018 09:35

Tungsten disulfide is the smoothest new solid lubricant in the current thousands of materials. It has been widely used in the automotive industry, and the benefits to the car are numerous.

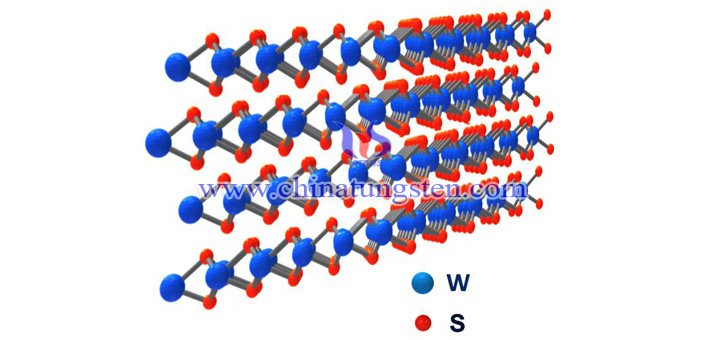

Tungsten disulfide is a layered crystal structure with excellent lubricity, very low friction coefficient, dynamic friction coefficient of 0.030, static friction coefficient of 0.070, coated on the surface of automotive parts, which can greatly reduce wear, bite, etc. Or reduce the problems of equipment maintenance and maintenance caused by friction, wear, etc., improve the working efficiency and service life of the automobile parts, saving time and cost for the user. The chemical properties of tungsten disulfide are relatively stable, can adapt to a variety of extremely harsh conditions, provide maximum protection against wear, rust, corrosion, and environmental protection, is non-toxic, will not cause harm to human health, The environment forms pollution.

The following are examples of the application of several tungsten disulfide in the automotive industry.

When the car engine is running, the temperature will be high, and the piston will rotate back and forth at a very high speed. Operating under such harsh conditions, the piston accelerates wear. Because of the low coefficient of friction of tungsten disulfide, parts used for high temperature or heavy load friction can also maintain lubrication. At this time, it is coated on the surface of the piston, which will reduce wear, lower temperature and prolong service life.

The old driver will probably know that the piston ring is the least durable part on the engine. The piston ring rotates at high speed with the piston and is subjected to the action of high temperature and high-pressure gas in the cylinder. The oil at high temperature is particularly prone to deterioration, so its wear is very serious. With tungsten disulfide, the friction can be reduced, and it can be happy with the piston under the conditions of high speed, high pressure, high temperature and extremely difficult lubrication!

The crankshaft is the most important part in the engine. Its working condition is also high-speed rotation, so it must be able to withstand wear and fatigue. The surface of the journal is generally subjected to high-frequency quenching or nitriding treatment. The surface of the journal is coated with tungsten disulfide and refined, and its wear resistance and fatigue strength are greatly improved.

The universal joints, steering knuckles, spring steel bushings, and front and rear brake cam bushings in automobiles are relatively difficult to apply oil. In frequent operation, the lubricants applied will deteriorate and lose lubrication. The tungsten disulfide has excellent mechanical stability and thermal stability, which can ensure the lubrication and wear reduction of these parts.

Tungsten disulfide has excellent compatibility, water wash resistance, and affinity with most paints, solvents and fuels. It ensures that the surface of the bearings in the pump and silicone oil fan clutch and the helical gears that drive the distributors always have a layer of lubrication for rust and corrosion protection. Tungsten disulfide has such excellent performance that it can be used not only in the automotive industry, but also in the mechanical industry, the plastics industry, the medical device industry, as well as military, aerospace and satellite, aviation and other high-tech fields.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com