Tungsten Alloy Swaging Rod for GBU-53/B

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 16:05

- Hits: 1776

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. GBU-53/B is planning to use tungsten alloy swaging rod as raw materials of its warhead.

The GBU-53/B is an American air-launched, guided bomb. Development was started in 2006 for a 250 pounds (113 kg) class bomb that can identify and strike mobile targets from standoff distances in all weather conditions. It will be integrated on the F-15E and F-35 Joint Strike Fighter. Its first flight was announced on May 1, 2009.

GBU-53/B takes advantage of density and hardness of tungsten alloy swaging rod to destroy underground bunker.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for GBU-44/B

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 15:54

- Hits: 1667

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten  alloy swaging rod has been widely used for GBU-44/B.

alloy swaging rod has been widely used for GBU-44/B.

The GBU-44/B is a GPS-aided laser-guided variant of the Northrop Grumman Brilliant Anti-Tank (BAT) munition which originally had a combination acoustic and IR seeker. The system was initially intended for use from UAVs, and it is also planned to integrate the weapon with the Lockheed AC-130 gunship, giving that aircraft a precision stand-off capability. The Viper Strike is now produced by MBDA.

With the high density and hardness of tungsten alloy swaging rod, GBU-44/B can penetrate armor and destry armor vehicle.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for GBU-27

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 15:37

- Hits: 1586

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod has been widely used for GBU-28.

GBU-28 is a 5,000-pound (2,268 kg) laser-guided "bunker busting" bomb nicknamed "Deep Throat" produced originally by the Watervliet Arsenal, Watervliet, New York. It was designed, manufactured, and deployed in less than three weeks due to an urgent need during Operation Desert Storm to penetrate hardened Iraqi command centers located deep underground. Only two of the weapons were dropped in Desert Storm, both by F-111Fs.

Tungsten alloy swaging rod has high density and high hardness which can help GBU-28 penetrate the rock formation and destroy underground bunker.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for GBU-57

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 15:26

- Hits: 1794

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod has been widely used for GBU-57.

GBU-57 is a U.S. Air Force, precision-guided, 30,000-pound (13,608 kg) "bunker buster" bomb.[2] This is substantially larger than the deepest penetrating bunker busters previously available, the 5,000-pound (2,268 kg) GBU-28 and GBU-37.

Tungsten alloy swaging rod has high density and high hardness which can help GBU-57 penetrate the rock formation and destroy underground bunker.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Vibration of Tungsten Bucking Bar

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 15:18

- Hits: 1781

The bucking bars made of tungsten resulted in significantly less vibration measured at the bucking bar when compared to the other two bucking bar materials (cold rolled and stainless steel). The >90% tungsten bar resulted in a 34% decrease in the resultant weighted acceleration when compared to using the cold rolled bar, and a 37.5% decrease when compared to using the stainless steel bar. Additionally, the >90% tungsten bar resulted in 2.8% less vibration transmission than the 90% tungsten bar, although this difference was not statistically significant. The magnitude of the weighted resultant acceleration indicates how fast the bucking bar is “bouncing” or moving as the energy is transferred from the rivet gun through the rivet to the bucking bar. Thus, a bucking bar that is accelerating less would be expected to result in lower grip force to control the bucking bar. Thus, when using bucking bars of the same size, the heavier tungsten bars were superior to the traditional steel bucking bars in terms of dampening vibration transmission without the added cost of increased muscle force to control the bars during riveting. This may also result in a positive health effect as the tungsten bucking bars resulted in an increase in the estimated duration for 10% of the exposed population at the measured acceleration levels to show symptoms of finger blanching (ISO 5349) of at least 49% and 64% when compared to the cold rolled and stainless steel bars, respectively.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

Tungsten Bucking Bars for Riveting Task

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 15:08

- Hits: 1720

Recently, bucking bars made of tungsten have been utilized for some riveting tasks at a local

aircraft manufacturer, where subjective reports from the employees suggested less vibration was

transmitted to the hands. However, since the tungsten bars weigh approximately 2.3 times more

than the steel bucking bars of the same size and shape, the company was reluctant to implement

tungsten bucking bars on a full scale. While the increased mass of the tungsten bar may be an

advantage as far as dampening the vibration, the effect on the hand grip exertion levels was

unknown. Therefore, the overall objective of this study was to perform a field evaluation to quantify

and compare the vibration transmission and grip muscle activity characteristics when using bucking bars of the same size and shape, but made of different materials.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

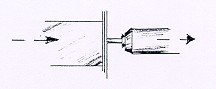

Bucking Bar and Rivet

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 15:04

- Hits: 1740

Although the use of composite materials is increasing in the manufacturing of aircraft, manual

riveting operations are still very pervasive in the assembly of aircraft. Riveting operations in aircraft manufacturing involves the use of power tools for manually drilling and countersinking holes for the rivets, as well as the use of air hammers or rivet guns to drive and set the rivets. Additionally, to close the rivet, the rivet is driven against a metallic bar commonly called a “bucking bar”. The bucking bars are typically held manually, and must be held firmly to increase the quality of the riveting, as well as keep the bucking bar from “dancing” against the metal piece being riveted.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

Ergonomic Field Assessment of Tungsten Bucking Bars During Riveting Tasks

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 14:57

- Hits: 1758

Riveting tasks in aircraft manufacturing results in exposure to vibration from both rivet guns and bucking bars. Long term exposure to vibration has been associated with symptoms of vibration white finger and musculoskeletal disorders. Four different bucking bars of the same shape but different material and mass characteristics (90%tungsten, >90% tungsten, cold rolled and stainless steel) were investigated for vibration and grip muscle activity during a riveting task. The >90% and 90% tungsten bars (3.4m/s and 3.6 m/s2, respectively) resulted in significantly less mean resultant weighted acceleration when compared to the cold rolled and stainless steel (5.3 m/s2 and 5.6m/s2, respectively), whereas there was no difference in mean hand grip flexor or extensor muscle activity. These results suggest that for bucking tasks that allow access for the bucking bar size investigated, use of heavier but same sized tungsten bucking bars can reduce vibration transmission to the hand.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

Tungsten Bucking Bar and Steel Bucking Bar

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 14:52

- Hits: 1653

Tungsten bucking bars are the bars to call on when space is limited! Almost twice as heavy as conventional steel bucking bars of the same size.In addition to use in tight areas, Tungsten bucking bars also significantly reduce vibration and greatly improve operator comfort. Tungsten bucking bars cost significantly more than standard steel bars but once you have used one, you will never regret your purchase. One tungsten bucking bar can take the place of many conventional steel bucking bars.

All surfaces are polished to permit bucking on any side of the bar and all corners are radiused to prevent material damage.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

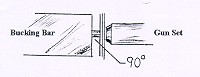

Bucking Bar Orientation

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 14:02

- Hits: 1567

1. Rest bucking bar on inserted rivet and try to locate its point of balance.

2. With gun set in place, use bucking bar to push rivet (and gun assembly) outward. Bucking bar will then register at right angles to the rivet as it comes to rest on the aluminium.

3. Push rivet back into place with gun set and reposition bucking bar, if necessary, to maintain its point of balance on the rivet. (repeat steps 2 and 3 until point of balance is determined). Often the index finger can be placed on the back of the bucking bar directly opposite the rivet tail. It then becomes the 'sensor' for correct bar position.

4. Pressure is held on gun while riveting. Bucking bar is held with only moderate force (otherwise rivet may be set with head proud of surface). A rubber grommet may be used over the rivet tail to assist in squeezing parts together during riveting. It acts as a 'pressure plate'

5. Duration of riveting is determined by experimentation with a test piece or previous experience.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com