Precision Bucking Bar Devices

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 08:55

- Hits: 1774

Previous attempts have been made to develop a precision bucking bar which will produce a consistent butt regardless of operator skill. Such bucking devices suffer from a number of limitations. For example, they have universally required a relative large space behind the rivet, a luxury not available in many installations; they have not been available in a variety of geometries to avoid nearby obstacles; and they have not been of a conventional shape or size and thus have not felt familiar to an experienced operator. Hence, prior art precision bucking bars have not been well received in the field.

A second method for spreading a rivet employs an apparatus commonly known as “squeezes.” Squeezes typically include a pair of removable anvils, or points, a first point shaped to receive a rivet head, and a second provides a flat surface to interface the flat end of a rivet shank. To spread a rivet with a pair of squeezes, the rivet must be close enough to the edge of the workpiece for the squeezes to reach the rivet. The rivet is placed in a hole through multiple layers of sheet metal to be joined, the anvils are placed against each end of the rivet, and the operator squeezes the handle together to produce a compressive force between the head of the rivet and the end of the shank, thereby causing the rivet to spread. Automatic squeezes are also available wherein the points are pressed towards each other by a pneumatic or hydraulic actuator. As with driving a rivet, producing a quality butt requires the operator to maintain a consistently square angle between the face of the flat anvil and the rivet shank. Producing a consistent, quality butt requires an experienced operator.

Common to either type of spreading operation, a properly shaped butt of consistent thickness is essential to achieving maximum strength of the riveted joint. An improperly shaped butt may be too weak to hold under expected stresses or may concentrate stress in a small area resulting in failure of the workpiece.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Precision Bucking Bar

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 08:54

- Hits: 1624

A precision bucking bar comprising a unitary rigid structure having a bucking surface thereon and a sidewall extending from the bucking surface such that, during a spreading operation, the bucking surface cannot contact the workpiece, thus producing a square butt of uniform thickness and a method for using the same. In another embodiment, the bucking surface is incorporated into a squeeze point for squeezers.

.A precision bucking bar for spreading a rivet through a workpiece comprising: a solid unitary structure having at least a first bucking surface thereon, said bucking surface having a first side wall, wherein said first side wall extends outwardly from said first bucking surface such that, when a rivet is spread, said first side wall will prevent said first bucking surface from contacting the workpiece.

A bucking bar is basically a metal anvil which is placed against the end of the shank of a rivet. Typically, a flat surface of the bucking bar interfaces a flat end of a rivet shank. The head of the rivet is then “hammered” by a driver, thereby causing the shank to spread against the bucking bar. To produce a properly shaped butt of proper thickness, prior art bucking bars have required a skilled operator. Failure of the operator to hold the bucking bar square against the rivet shank will result in misshaped butts and bad rivet resulting in costly rework. Furthermore, prior art bucking bars are prone to wandering during the spreading operation and occasionally wander off the shank, likewise resulting in a bad rivets and subsequent rework.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Powder Typical Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 20:34

- Hits: 1182

1) Machine tools

Tungsten carbide cutting surfaces are often used for machining through materials such as carbon or stainless steel, as well as in situations where other tools would wear away, such as high-quantity production runs. Most of the time, carbide will leave a better finish on the part, and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools. The material is usually called cemented carbide, hardmetal or tungsten-carbide cobalt: it is a metal matrix composite where tungsten carbide particles are the aggregate and metallic cobalt serves as the matrix.

2) Military

a) Tungsten carbide is often used in armor-piercing ammunition, especially where depleted uranium is not available or not politically acceptable. The first use of W2C projectiles occurred in German Luftwaffe tank-hunter squadrons, which used 37 mm autocannon equipped Junkers Ju 87G dive bomber aircraft to destroy Soviet T-34 tanks in World War II. Owing to the limited German reserves of tungsten, W2C material was reserved for making machine tools and small numbers of projectiles for the most elite combat pilots, like Hans-Ulrich Rudel. It is an effective penetrator due to its high hardness value combined with a very high density.

b) Tungsten carbide ammunition can be of the sabot type (a large arrow surrounded by a discarding push cylinder) or a subcaliber ammunition, where copper or other relatively soft material is used to encase the hard penetrating core, the two parts being separated only on impact. The latter is more common in small-caliber arms, while sabots are usually reserved for artillery use.

c) Tungsten carbide is also an effective neutron reflector and as such was used during early investigations into nuclear chain reactions, particularly for weapons. A criticality accident occurred at Los Alamos National Laboratory on 21 August 1945 when Harry K. Daghlian, Jr. accidentally dropped a tungsten carbide brick onto a plutonium sphere, causing the sub-critical mass to go critical with the reflected.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for JDAM

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 16:13

- Hits: 1669

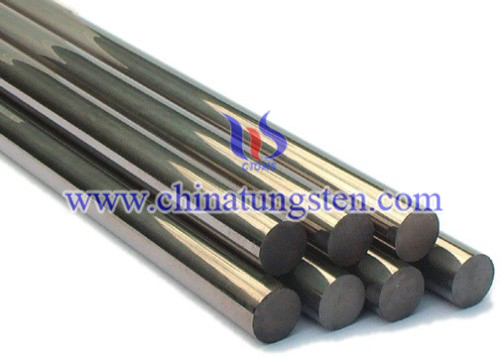

Tungsten alloy swaging rod is made of tungsten rod. The density, hardness and strength of tungsten alloy swaging rod is higher than tungsten alloy rod. Tungsten alloy swaging rod has been widely used for JDAM.

JDAM is a guidance kit that converts unguided bombs, or "dumb bombs" into all-weather "smart" munitions. JDAM-equipped bombs are guided by an integrated inertial guidance system coupled to a Global Positioning System (GPS) receiver, giving them a published range of up to 15 nautical miles (28 km). JDAM-equipped bombs range from 500 pounds (227 kg) to 2,000 pounds (907 kg). When installed on a bomb, the JDAM kit is given a GBU (Guided Bomb Unit) nomenclature, superseding the Mark 80 or BLU (Bomb, Live Unit) nomenclature of the bomb to which it is attached.

JDAM contains shaped charge warheads which made by tungsten alloy swaging rod to destroy undergound bunkers.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for CBU-24

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 15:54

- Hits: 1755

Tungsten alloy swaging rod is made of tungsten rod. The density, hardness and strength of tungsten alloy swaging rod is higher than tungsten alloy rod. Tungsten alloy swaging rod has been widely used for CBU-24.

The CBU-24 (Cluster Bomb Unit-24) is an unguided, aircraft delivered anti-personnel and anti-materiel weapon developed by the United States. Because it is an unguided weapon, the CBU-24 can be carried and dropped by any aircraft capable of carrying standard "dumb" or "iron" bombs.

The CBU-24 cluster bomb consists of a SUU-30 dispenser unit containing a payload of 665 tennis ball-sized BLU-26 or BLU-36 fragmentation submunitions, also known as bomblets.[1] Once dropped from the delivery aircraft, the CBU-24 casing breaks open in-flight and releases the individual submunitions, scattering them over a large area.

CBU-24 contains shaped charge warheads which made by tungsten alloy swaging rod to pierce armor and destroy tanks.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for BL755

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 15:43

- Hits: 1669

Tungsten alloy swaging rod is made of tungsten rod. The density, hardness and strength of tungsten alloy swaging rod is higher than tungsten alloy rod. Tungsten alloy swaging rod has been widely used for BL755.

BL755 is a cluster bomb. Its primary targets are armored vehicles and tanks with secondary soft target (anti personnel) capabilities.

The MW-1 was designed so that different types of submunitions may be loaded into its 112 tubes. The MIFF, MUSA and MUSPA mines are parachute dropped, and upon reaching the ground self-right and arm. The mines are blast-resistant and are reported to have a self-destruct devices giving them a lifespan of less than forty days.

The BL755 looks like a standard 450 kilograms (1,000 lb) general purpose bomb but with a hard "saddle" on the spine for ejector release and crutching pad loads and a distinctive large turbine-like air arming vane on the nose. The four rear fins are squared off in appearance, but on closer inspection can be seen to be hollow and telescopic. A central extruded aluminum skeleton provides seven bays long by seven bays around, each containing 21 submunitions (147 total). The submunitions are ejected by means of a central cartridge and individual inflatable bladders for each bay, operating in a similar manner to a car airbag. Ejection on the original BL755 bomb is triggered by the rotation of the arming vane, driven by the airflow.

BL755 contains shaped charge warheads which made by tungsten alloy swaging rod to pierce armor and destroy tanks.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for MW-1

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 15:33

- Hits: 1638

Tungsten alloy swaging rod is made of tungsten rod. The density, hardness and strength of tungsten alloy swaging rod is higher than tungsten alloy rod. Tungsten alloy swaging rod has been widely used for MW-1.

The MW-1 is a German munitions dispenser similar to the British JP233. It is designed to be carried on the Tornado IDS, although it can be carried on the F-104 Starfighter and the F-4 Phantom.[1] Since the German Government decision to support the ban on cluster ammunition, the MW-1 is currently being phased out.

The MW-1 was designed so that different types of submunitions may be loaded into its 112 tubes. The MIFF, MUSA and MUSPA mines are parachute dropped, and upon reaching the ground self-right and arm. The mines are blast-resistant and are reported to have a self-destruct devices giving them a lifespan of less than forty days.

MW-1 contains shaped charge warheads which made by tungsten alloy swaging rod. With tungsten alloy swaging rod, MW-1 destroys runways efficiently.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for JP233

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 15:16

- Hits: 1696

Tungsten alloy swaging rod is made of tungsten rod. The density, hardness and strength of tungsten alloy swaging rod is higher than tungsten alloy rod. Tungsten alloy swaging rod has been widely used for JP233.

Originally known as the LAAAS (Low-Altitude Airfield Attack System), the JP233 was a British submunition delivery system consisting of large dispenser pods carrying several hundred submunitions designed to attack runways.

JP233 contains shaped charge warheads which made by tungsten alloy swaging rod to destroy runways. JP233 had good performance in Gulf War.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for Durandal

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 15:07

- Hits: 1549

Tungsten alloy swaging rod is made of tungsten rod. The density, hardness and strength of tungsten alloy swaging rod is higher than tungsten alloy rod. Tungsten alloy swaging rod has been widely used for Durandal.

Named for a mythical medieval French sword, the Durandal is a bomb developed by the French company Matra (now MBDA), designed to destroy airport and airfield runways and exported to a number of countries worldwide. As a simple crater in a runway could be just filled in, the Durandal deliberately utilizes two explosions in order to displace the concrete slabs of a runway, damage that is far harder to repair.

Durandal contain shaped charge warheads which made by tungsten alloy swaging rod to destroy run way.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod for Cluster Munition

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 October 2013 14:59

- Hits: 1285

Tungsten alloy swaging rod is made of tungsten rod. The density, hardness and strength of tungsten alloy swaging rod is higher than tungsten alloy rod. Tungsten alloy swaging rod has been widely used for cluster munition.

A cluster munition is a form of air-dropped or ground-launched explosive weapon that releases or ejects smaller submunitions. Commonly, this is a cluster bomb that ejects explosive bomblets that are designed to kill personnel and destroy vehicles. Other cluster munitions are designed to destroy runways or electric power transmission lines, disperse chemical or biological weapons, or to scatter land mines. Some submunition-based weapons can disperse non-munitions, such as leaflets.

Most cluster munitions contain shaped charge warheads which made by tungsten alloy swaging rod to pierce the armor of tanks and armored fighting vehicles.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com