Tungsten Ball

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 11:23

- Hits: 2043

Tungsten ball is the general term for pure tungsten ball, tungsten alloy ball and tungsten carbide ball.

Pure tungsten ball is used the material of pure tungsten whose density is over 19.2g/cm3, and it is the highest density among tungsten balls. Another reason for applicator using pure tungsten ball is that tungsten ball has the highest melting point.

Tungsten alloy ball is tungsten ball alloy with Ni and Fe, or other metal element to improve other properties of tungsten, such as to make unbrittle and easy to be processed. Tungsten alloy ball can be marked words on the ball, but pure tungsten ball has no such properties.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Needles

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 11:18

- Hits: 2040

Tungsten needles are widely used in the construction of furnace tooling and parts and as a feedstock for the fabrication of parts for the electronics and semiconductor industries. Surface can be supplied in a shiny or matte; dependent upon the thickness and width parameters.

Tungsten needles grow from hexacarbonyl tungsten vapors in a glow-discharge condition are described. The needle growth occurs on a tungsten substrate in a temperature range from nearly room temperature to 1500 °K, but needles produced below and above ~1100 °K are quite different in morphology and crystalline state. The products at lower temperatures are tungsten particles agglomerated in dendrite like shapes while those at higher temperatures possibly are whiskers.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Pin

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 11:09

- Hits: 1960

Tungsten pin is pin made of the material—tungsten. Since it is made of tungsten, tungsten pin owns the properties of high melting point, high corrosion resistance, tensile strength and low coefficient of thermal expansion. When added steel or other element, its hardability would be improved.

The surface condition of tungsten pin is smooth and bright. Moreover, no stain, dirt, oxides, drawing tracks, scratches and damages are admitted on the surface of tungsten pin.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Radiation Cover

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 10:59

- Hits: 2157

Tungsten alloy radiation cover has been used for several decades now. The early radiation cover was not ver y efficient and very expensive due to technological reasons. It was used by the people who worked on radar and microwave transmission. As the development of the technology, the efficiency of the radiation cover has been highly enhanced; it can efficiently resist and refract the X-ray, UV, microwave radiation and so on.

y efficient and very expensive due to technological reasons. It was used by the people who worked on radar and microwave transmission. As the development of the technology, the efficiency of the radiation cover has been highly enhanced; it can efficiently resist and refract the X-ray, UV, microwave radiation and so on.

As radiation level rise and becomes a problem, it is crucial to protect body from it. Tungsten alloy radiation cover for plasma accelerator is necessary. Because of high density and smallest capacity, tungsten alloy material is gaining popularity as body protection, tungsten radiation cover against plasma accelerator radiation. Compared with lead, tungsten is much smaller but with higher density, which is very helpful for high radiation absorption. It is more than 60% denser than lead with excellent machinability and good corrosion resistance. And more important, tungsten ally is environmentally friendly and non-toxic.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Indoor Weight

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 10:45

- Hits: 2104

Tungsten alloy indoor weight is a product that can help you to become fit. It can increase strength, i mprove coordination and maintain the balance of the body ability in the rotation of the high speed.

mprove coordination and maintain the balance of the body ability in the rotation of the high speed.

Tungsten alloy is a very suitable material for indoor weight throw. Instead of using iron or lead you can now use high density, high melting point, small volume, excellent hardness, superior wearing resistance, high ultimate tensile strength, high ductility, high temperature resistance, etc. It is a perfect material to manufacture indoor weight in variety of shapes such as dumbbell, weightlifting, balls etc.

High density tungsten alloy indoor weight can help you to improve your performance. It is non-toxic and environmentally friendly, so it is another advantage for it. It does not harmful to people's body when they practice it for a long time. Tungsten alloy is also very easy to machine, so a lot of time and effort can be saved in the process of making it. Good corrosion resistance is another advantage for tungsten alloy to make indoor weight. Long use, sweat and atmospheric conditions can cause other materials to corrode, but tungsten alloy is so durable and resistant that it will look as new even after long time.

Whether you are a professional amateur looking to improve shape or elite college athlete, tungsten alloy indoor weight provides the greatest mechanical advantages of over any other weight on the market, resulting in measurably longer throws; this weight could help you make it to the next level.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Worm Weights

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2013 10:38

- Hits: 2075

Tungsten alloy worm weights, a kind of bullet fishing weights, are also called "tungsten heavy alloy worm weight". They provide ideal, environmentally friendly alternative to lead weights, as it is toxic and increasingly being labeled an environmental hazard. Tungsten alloy worm weights are harder than steel and extremely dense, tungsten is on average 30% smaller than its lead counterpart is. Tungsten alloy worm weights are smaller than conventional weights, create twice the sound of lead weights and maintain their shape for longer.

Tungsten alloy worm weights are usually made from 95%W to 97%W and molded into a "flipping" style, and it is friendly to environment, so it is superior to lead weights. Due to the high grade of tungsten alloy, the profile is up to 60% smaller compared to lead weights, 10% smaller than the competing brand of tungsten alloy "worm" weights, making them very subtle in presentation. Chinatungsten worm weights are super sensitive, giving the angler the advantage of feeling every bite and underwater environmental changes, such as powder-coated black or green pumpkin for a durable finish.

Void of an insert, allowing the use of 80lb braid or 25lb fluorocarbon with ease, burr-free weights that give clients the ultimate confidence in line protection.

Tungsten alloy worm weights will be used with a fishing line, so there should be a very smooth through hole for the weight, Chinatungsten can offer quality tungsten alloys worm weights to protect the fishing line from breaking. We usually provide a plastic insert for the weight; you can find the following tungsten heavy alloy worm weight.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Oil Logging Counterweight

- Details

- Category: Tungsten Information

- Published on Monday, 01 July 2013 15:26

- Hits: 2075

Usually, when it comes to environmental or geotechnical studies about groundwater, mineral, oil and gas exploitation, it is necessary to utilize tungsten alloy logging counterweight to perform well logging, and analyze stratum situation exactly when drilling boreholes.

Because oil logging needs to enter the earth as deeper as possible to get the characterization of wells, high-performance logging facility is required, and tungsten alloy logging counterweight should be heavy and firmer enough, to balance out much more upward resistance and enhance the downward impulse force. In fact, tungsten alloy works as counterweight for the whole part.

Tungsten heavy alloy (WHA) is an excellent casing material for oil logging counterweight down-hole lo gging of oil wells. Casings must be sufficiently heavy to readily sink through materials such as barite mud and strong enough to withstand the hydrostatic pressure of this harsh environment. Most designs of tungsten alloy oil logging counterweight are highly machined for sensor and window positioning. Mechanical properties are very significant to the survivability of tungsten alloy oil logging counterweight rather large components.

gging of oil wells. Casings must be sufficiently heavy to readily sink through materials such as barite mud and strong enough to withstand the hydrostatic pressure of this harsh environment. Most designs of tungsten alloy oil logging counterweight are highly machined for sensor and window positioning. Mechanical properties are very significant to the survivability of tungsten alloy oil logging counterweight rather large components.

Because of high density as 18.5g/cm3 max, hardness as 36 HRC max, high wear-resistance, high impact resistance and excellent durability, tungsten heavy alloy (WHA) is very suitable material for oil logging counterweight down-hole logging of underground water, oil and gas, etc. Special mechanical property is overweight large component in tungsten alloy oil logging counterweight.

Tungsten heavy alloy related to petroleum industry we can offer various tungsten heavy alloy counterweight, such as tungsten alloy oil logging counterweight, also we would like to design the drawing or manufacture concrete products according to customer's special requirements. Tungsten alloy oil logging counterweight we offered are in pressed & sintered blanks large enough to yield the desired component or machined components to customer's specifications.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

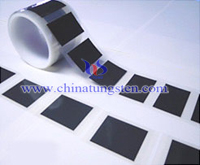

Tungsten Alloy Shielding Sheet

- Details

- Category: Tungsten Information

- Published on Monday, 01 July 2013 15:12

- Hits: 2050

Previously, hard heavy metal sheets have been used to shield against radiation. By contrast, the recently developed tungsten alloy shielding sheet made with thermoplastic lassoers is a light weight and very flexible shielding material. Tungsten alloy shielding sheet is expected to have a wide range of uses, such as to reduce radiation from entering rooms, and as covers for contaminated waste kept in temporary storage sites during decontamination.

The tungsten alloy shielding sheet was developed through collaboration, which has expertise in radiation gained from research on applications for the high-density elite containing fiber and Nihon Matai research laboratories, which have been developing packaging for heavy materials and various resin processing technologies over a number of years. A patent application has been filed based on repeated demonstration tests conducted in areas where there are still high levels of radiation in the air.

Going forward, urgent and continued efforts are needed to protect against radiation. To help in ensuring safety and peace of mind, we has applied tungsten alloy shielding sheet technology and know-how as a “General Packaging Industry,” accumulated over many years in packaging, to make a contribution to society in the area of radiation countermeasures.

The raw materials used in tungsten alloy have been proven to be safe and have no effect on the human body. Tungsten alloy shielding sheet is a high-polymer material that possesses the properties of both plastic and rubber.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

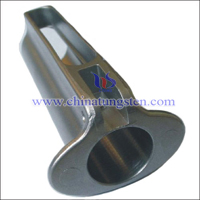

Tungsten Alloy Shielding Tube

- Details

- Category: Tungsten Information

- Published on Monday, 01 July 2013 15:03

- Hits: 2152

Tungsten alloy shielding tube has high melting temperature, high strength, good thermal conductivity and  spelling resistance. Shielding tube can be used as the parts of electron shielding tube and the heating elements of the high temperature furnace.

spelling resistance. Shielding tube can be used as the parts of electron shielding tube and the heating elements of the high temperature furnace.

Tungsten alloy shielding tube that made of tungsten alloy will have excellent effect to protect electromagnetic waves.

Tungsten alloy shielding tube has very high magnetic permeability compared to other materials. Permeability is the degree of magnetization of a material that responds linearly to an applied magnetic field. Tungsten alloy shielding tube can divert magnetic flux and effectively protect sensitive.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Radiation Cap

- Details

- Category: Tungsten Information

- Published on Monday, 01 July 2013 14:53

- Hits: 2155

As medical science developing so repaid, there is more and more radiation in our life, which has become a new trouble, such as X-ray radiation, gamma radiation (energetic electromagnetic radiation), radiation of alpha particles (helium atoms) beta particles (electrons) and cosmic radiation, etc. Tungsten alloy radiation cap protect us from the radiation. Tungsten alloy radiation cap is better than shielding made by other materials.

Tungsten alloy radiation cap is ideal product against X rays and gamma radiation. The very high density of tungsten alloy cap allows a reduction in the physical size of shielding cap, without compromising their rigidity or the effectiveness of the tungsten alloy radiation shielding characteristics.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com