Cutting Edge Geometry Effects On Tungsten Carbide Inserts Coating Process

- Details

- Category: Tungsten Information

- Published on Friday, 03 July 2015 14:56

- Written by lucy

- Hits: 333

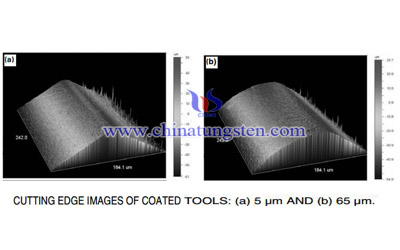

In practical machining application, it has been pointed out that the cutting edge geometry has compound effects on tungsten carbide inserts coating process, and the cutting edge radius affects the deposition stresses and machining loads in an opposite way. Specially, under different cutting condition, the optimal radius maybe varied from one to another since the edge radius effects on machining loads are depended on machining parameters.

In the coating process like CVD processes, the thermal mismatch between the coating and substrate materials are likely to generate high residual stresses in the tool, and for the tungsten carbide insert’substrate, the cobalt cemented tungsten carbide receive a tensile stress, which tends to have impacts on the coating functions. Moreover, the geometric changes like cutting edges, will severely alter the local stress fields.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com