Advanced Nano Tungsten Powder Manufacturing Scheme

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 21:25

- Written by meiwei

- Hits: 992

With the development of high technology, the requirement for pure tungsten and its alloy materials is higher and higher. Whether tungsten wire, plate, foil, or other alloy materials based on tungsten (such as tungsten-copper electrical alloy, Tungsten-Nickel-Iron high specific gravity alloy, etc.) are required to have uniform structure, fine grain size and good plasticity. It also promotes the quality requirement of original tungsten powder. In the application, the particle size of advanced nano tungsten powder determines the powder metallurgy process and material properties of tungsten products. Nano-scale ultra-fine tungsten powder is becoming popular.

Read more: Advanced Nano Tungsten Powder Manufacturing Scheme

Metallographic Preparation of Plasma Sprayed Tungsten Carbide Coating

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:48

- Written by meiwei

- Hits: 1011

Tungsten carbide coating by plasma spraying is mainly used for anti-sliding friction, vibration friction, wear resistance and corrosion protection of aero-engines below 500 ℃. It has been widely used in aero-engines at home and abroad.

Read more: Metallographic Preparation of Plasma Sprayed Tungsten Carbide Coating

A Tungsten Lubricating Oil Additive

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:12

- Written by meiwei

- Hits: 1086

Diesel engine oil is mainly composed of paraffin base oil or synthetic lubricant, which is prepared by adding many additives such as antioxidant, antiseptic, detergent and dispersant, antifriction agent and so on.

Molybdenum Silicide Coating for Niobium Tungsten Alloy Combustor of Engine

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:23

- Written by meiwei

- Hits: 844

Bipropellant attitude and orbit control engine is an important part of modern space vehicles and strategic and tactical weapons, which is widely used in orbit control, attitude adjustment and so on. In recent years, with the development of new aircraft or weapons, the requirement for engine performance has been increasing. It requires that specific impulse be increased and chamber pressure be increased, so as to reduce propellant consumption and engine weight, prolong engine life or increase the range of strategic weapons.

Read more: Molybdenum Silicide Coating for Niobium Tungsten Alloy Combustor of Engine

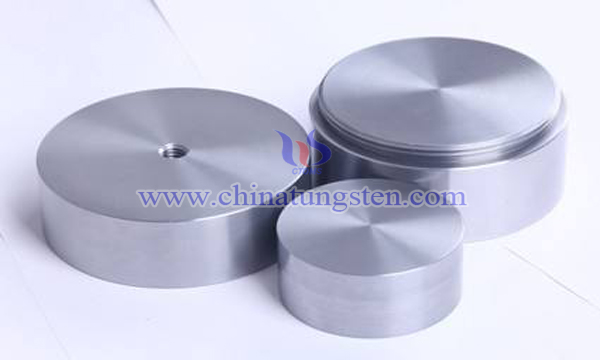

Tungsten Molybdenum Alloy Sputtering Targets

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:07

- Written by meiwei

- Hits: 1091

Tungsten molybdenum alloys can be used at higher temperatures than molybdenum or molybdenum alloys. Molybdenum-tungsten alloy has better conductivity, oxidation resistance and lower coating stress than molybdenum, which meets the requirement of sputtering target material for flat display film production line. Especially the Mo-W alloy with tungsten content of 3.5%25% is more suitable for high quality flat panel display.

sales@chinatungsten.com

sales@chinatungsten.com