Pressing Mode of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 17 July 2017 17:19

- Written by bifeng

- Hits: 402

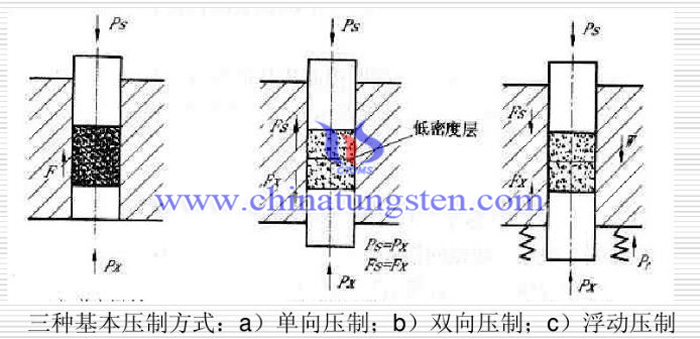

Single Action Pressing

Cavity block and undershoot hold-on in the forming process,only provided uprush imposed pressing pressure to powder.Single action pressing usually used in products which height-diameter ratio is H/D≤1 or some sleeve parts which wall thickness ratio is H/T≤3.

Features:

1.Density distribution is nonuniform;

2.Neutral axis place is close to the bottom of compaction;

3.H or H/D increase,density contrast increase;

4.Mold structure simpleness,efficient production;

5.Be suitable for lower in height,big thickness compaction

Double Action Pressing

When in the forming process,hollowing block( Cavity block)hold-on ,up-down punch (terrace die) exert a certain amount of force in the opposite ways.According to wether pressing is at the same time it can also be divided into coincident double action pressing and non-coincident double action pressing( post-pressing).Former up-down punch compose equal pressure to powder compact simultaneously,after later accomplished a single action pressing,then go on a single action pressing in a lower density

Features:

1.Equal to two superposition of single action pressing;

2.Neutral axis is not in the bottom of compaction;

3.In the same pressing condition,density contrast is smaller than single action pressing;

4.Can be used in pressing which is bigger than H/D compaction.

Floating Pressing

Uprush put pressure on powder in the pressing process, undershoot hold-on,cavity block can float up or down through the proper support of spring,air cylinder and oil cylinder.When pressing,put pressure on the uprush,with powder be compressed,friction between cavity block walls and powder gradually increased.When friction bigger than spring’s support force(floating force),cavity block and upper punch decrease at the same time,it is equivalent to blanking punch rise and opposite pressing play a part in double action pressing.Floating pressing except cavity block floating,mandrel can also floating,at the same time density distribution equal to double action pressing.If cavity block floating,mandrel hold-on,then compaction which close to cavity block is equivalent to double action pressing,the middle density is lowest;compaction where close to mandrel is like upper punch move down of single action pressing.bottom density is lowest.Floating pressing applicable to parts of H/T≤6 or H/D≥2.

Features:

1.Pressing effect is resemblance to double action pressing;

2.Compaction density distribution is equivalent to double action pressing;

3.The location of neutral axis is relate to support force;

4.Convenient for dress up;

5.The bottom of press only need lesser pressing and ejection pressure.

Pull Down Pressing

It’s also known as pull down force,strong force pressing.When pressing start,upper punch pull down a certain distance,then decrease with cavity block (cavity block is compel to pull down) cavity block’s descent velocity can be adjust.The drawn distance is equivalent to the distance of floating.When the pressing stop,upper punch rise again,cavity block to pull down further in order compaction can be take off.Features is resemblance to project and floating pressing,some powder friction is small,can’t realize floating pressing,can also use this pressing mode.

Friction Mandre Pressing

When pressing,cavity block and blanking punch hold-on, upper punch compel mandrel to move down at the same time,and mandrel descending velocity is bigger than powder descending velocity,count on friction between mandrel and powder can drive powder to move down,so that to improve the density distribution inhomogeneity height direction along compaction.This mode can be used in pressing slender thin-wall parts.of H/T>6-10.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com