Nickel-tungsten Alloy Plating Mold Analytic Process(a)

- Details

- Category: Tungsten Information

- Published on Thursday, 05 March 2015 08:54

- Written by Sherry

- Hits: 456

Insiders know that the quality of the parts is closely related to the quality of the mold. Many die (such as die casting) of the surface must be plated in order to improve the corrosion resistance, abrasion resistance, oxidation resistance and hardness properties. According to the HC surface network Xiaobian understand, despite the traditional chrome technology mature technology, stable quality, but because chromium is a toxic substance, serious environmental pollution. Therefore, the elimination of pollution, environmental protection, clean production, the path of sustainable development.

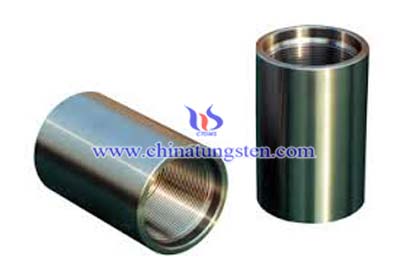

Nickel-tungsten alloy plating is to improve the quality of mold, to extend die life, a good choice for clean production. Nickel, tungsten high hardness, wear resistance, and molten matrix adhesion and high temperature. Fine crystalline nickel-tungsten alloy plating bright, good wear resistance, combined with the strong base, high hardness, Vickers hardness at elevated temperatures up to 1000 or more. The technology in recent years by the parties concerned, will gradually replace the mold chrome plating, however, according to HC Xiao Bian understood that the technology prevailing coating roughness, uneven, pitting and other defects, severely restricts their application development. Let Xiaobian for you to resolve mold electroless nickel-tungsten alloy process recipe and process.

Bath formulation and process

Bath mainly composed of sodium tungstate, nickel sulfate and sodium citrate, whose contents were 40 ~ 45gL, 20 ~ 30gL, 40 ~ 50gL.

Process:

Sandblasting → Check → Degreasing Cleaning → Plating → Test

Coating quality defects and causes

Common tungsten nickel plating quality defect is pitting more rough side and white spherical particle coating, coating and central side corners and R at serious inequality, and even the corners, R occurring at the micro cracks.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com