Hunan high-performance rare earth materials project through acceptance

- Details

- Category: Rare Earth News

- Published on Wednesday, 16 October 2013 16:55

- Written by HJF

- Hits: 1679

Hunan Institute of Rare Earth Materials borne high performance rare earth materials research and industrial projects recently passed Changsha organization's project acceptance.

The Group believes that the project effectively promote green lighting industry in Hunan Province , the electronics industry , paint industry and other aspects of development , is conducive to the province 's rare earth resources advantages into industrial advantages. The project team developed a high-performance rare earth materials make energy-saving lamp switch 50000 times does not appear blackheads, average life of 30,000 hours or more ; established the first domestic microwave synthesis phosphor prepared multicomponent model production lines, advanced microwave heating methods are used. The project implementation process to establish an annual output of 200 tons of light rare earth phosphor production lines to produce 50 million fluorescent lamps and high power LED lamp production lines, to achieve annual sales income of 164 million yuan .

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Multiple Composite Rare Earth Tungsten Electrodes Swaging String Playing Equipment Technology Invented Concrete Steps

- Details

- Category: Rare Earth News

- Published on Wednesday, 16 October 2013 16:54

- Hits: 1699

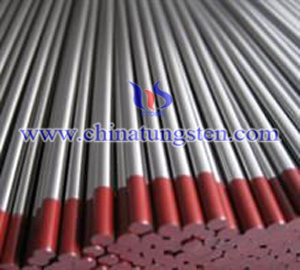

Multiple composite rare earth tungsten electrodes swaging string playing equipment and technology invention uses string playing devices relative position of each device is as follows : The first furnace tube length of 1m molybdenum wire furnace, the first furnace and the first rotary swaging machine 2 the distance between 15cm ( 15cm i.e. the gap between the two ) , the first guide roller and the first rotary forging machine and the distance between the second furnace are 10cm, the second furnace to furnace tube length 0.7m molybdenum wire tube furnace , and the second rotary forging machine 5 and the distance between the second furnace 15cm, and the second guide roller and the distance between 10cm.

B203 selected will pass the billet forging Φ6.5 string into boron oxide playing machine for processing , the blank of the composition: percentage by weight , of rare earth oxide content of 0.44% lanthanum oxide , yttrium oxide, 1.32% , 0.44% oxide cerium , and the balance tungsten, first the first furnace , a second heating furnace 4 heated to 1470 ℃, the billet feed speed is controlled 2m/min, the first step of setting a first rotary hammer 2 and the the second rotary hammer machine 5 with mold system as the Φ6.0, Φ5.6, the first guide roller 3 speed 2.3m/min, the second guide roller 6 speed is set to 2.7m/min, after the first procedure after processing , the billet into the distribution system as the model Φ5.2, Φ4.8 string play equipment for the second processing procedures , the first and second heating furnace 4 furnace a temperature set at : 1430 ℃, the first a guide roller 3 speed 2.3m/min, the second guide roller 6 speed is set to : 2.7m/min; billet into the match after molding system as : Φ4.4, Φ4.1 the third step processing the first and second heating furnace 4 furnace temperature was set at 1430 ℃, the first guide roller 3 speed of 2.4m/min, the second guide roller 6 speed to : 2.7m/min; three after the process , began to enter the B201 stage in the B201 stage tungsten processed through two processes , the first process with mold system as : Φ3.9, Φ3.6, first one and the second furnace temperature furnace 4 as : 1430 ℃ first guide roller speed of 2.2m/min, the second guide roller temperature to 2.6m/min. Second step with mold system as the Φ3.3, Φ3.0, first and second furnace temperature furnace 1 as : 1370 ℃. The first guide roller 3 speed 2.4m/min, the second guide roller 6 speed is set to : 2.9m/min, a variety of specifications available Φ6-Φ3 rare earth tungsten electrode material .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Multiple Composite Rare Earth Tungsten Electrodes Swaging String Playing Devices Embodiments of The Invention Process

- Details

- Category: Rare Earth News

- Published on Wednesday, 16 October 2013 16:50

- Hits: 949

Multiple composite rare earth tungsten electrodes swaging equipment and technology to fight the invention of string string playing devices using the relative position of each device is as follows : The first furnace tube length of 1m molybdenum wire furnace, the first furnace and the first rotary swaging machine 2 the distance between 15cm ( 15cm i.e. the gap between the two ) , the first guide roller and the first rotary forging machine and the distance between the second furnace are 10cm, length of the second furnace to furnace molybdenum wire is 0.7m tube furnace , rotary forging machine and the second distance between the second furnace 15cm, and the second guide roller and the distance between 10cm.

B203 selected will pass the billet forging Φ6.5 string into B202 playing machine for processing , the blank of the composition: percentage by weight , of rare earth oxide content of 0.44% lanthanum oxide , yttrium oxide, 1.32% , 0.44% CeO2, the balance being tungsten, the first of the first furnace , a second heating furnace 4 heated to 1500 ℃, the billet feed speed is controlled 3m/min, the first step of providing the first and second rotary rotary hammer machine hammer mold system as the machine is equipped Φ6.0, Φ5.6, the first guide roller speed 3.5m/min, the second guide roller speed is set to 4.0m/min, after processing through the first process , the billet placed with mold system as the Φ5.2, Φ4.8 string play equipment for the second processing procedures , the first and second furnace temperature furnace set at : 1450 ℃, the first guide roller speed is 3.5m / min, a second guide roller 6 speed is set to : 4.1m/min; billet into the match after molding system as : Φ4.4, Φ4.1 the third step in the processing of the first furnace and the second furnace temperature was set at 1450 ℃, the first guide roller speed 3.6m/min, the second guide roller speed is set to : 4.1m/min; three step is completed , began to enter the B201 stage in the B201 stage tungsten is processed through two processes , the first process with mold system as : Φ3.9, Φ3.6, first one and the second furnace temperature furnace set at : 1450 ℃ first guide roller speed is 3.3 m / min, the second guide roller temperature to 3.9m/min. Second step with mold system as the Φ3.3, Φ3.0, first and second furnace temperature furnace 1 as : 1400 ℃. The first guide roller speed 3.6m/min, the second guide roller speed is set to : 4.3m/min, a variety of specifications available Φ6-Φ3 rare earth tungsten electrode material .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

October 16 Price of rare earth products

- Details

- Category: Rare Earth News

- Published on Wednesday, 16 October 2013 16:52

- Written by HJF

- Hits: 1540

October 16 rare earth products price quotes

| Name | Specifications | Origin / Grade | Reference Price | Price | Change |

| Rare earth carbonate | REO 42.0-45.0% | Domestic | 27000-28000 yuan / ton | 27500 | 0 |

| Lanthanum oxide | La2O3/TREO 99.5-99.9% | Domestic | 27000-28000 yuan / ton | 27500 | 0 |

| Cerium oxide | CeO2/TREO 99.5-99.9% | Domestic | 26000-28000 yuan / ton | 27000 | 0 |

| Praseodymium oxide | Pr6O11/TREO 99.0-99.9% | Domestic | 560000-580000 yuan / ton | 570000 | 0 |

| Neodymium oxide | Nd2O3/TREO 99.0-99.9% | Domestic | 350000-355000 yuan / ton | 352500 | 0 |

| Samarium oxide | Sm2O3/TREO 99.5-99.9% | Domestic | 22000-24000 yuan / ton | 23000 | 0 |

| Europium oxide | Eu2O3/TREO 99.95-99.99% | Domestic | 4800-5000 yuan / kg | 4900 | 0 |

| Gadolinium oxide | Gd2O3/TREO 99.5-99.9% | Domestic | 185000-195000 yuan / ton | 190000 | 0 |

| Terbium oxide | Tb4O7/TREO 99.95-99.99% | Domestic | 4100-4200 yuan / kg | 4150 | 0 |

| Dysprosium oxide | Dy2O3/TREO 99.5-99.9% | Domestic | 1900-2100 yuan / kg | 2000 | 0 |

| Erbium oxide | Er2O3/TREO 99.5-99.9% | Domestic | 360000-370000 yuan / ton | 365000 | 0 |

| Yttrium oxide | Y2O3/TREO 99.995-99.999% | Domestic | 75000-85000 yuan / ton | 80000 | 0 |

| Praseodymium neodymium oxide | (Nd2O3 + Pr6O11) / TREO ≥ 75.0% | Domestic | 350000-355000 yuan / ton | 352500 | 0 |

| Lanthanum metal | La / TREM ≥ 99.0% | Domestic | 53000-55000 yuan / ton | 54000 | 0 |

| Cerium metal | Ce / TREM ≥ 99.0% | Domestic | 60000-65000 yuan / ton | 62500 | 0 |

| Praseodymium | Pr / TREM 96.0-99.0% | Domestic | 590000-610000 yuan / ton | 600000 | 0 |

| Neodymium | Nd / TREM 99.0-99.9% | Domestic | 440000-450000 yuan / ton | 445000 | 0 |

| Metal terbium | Tb / TREM ≥ 99.9% | Domestic | 4800-5000 yuan / kg | 4900 | 0 |

| Dysprosium | Dy / TREM ≥ 99% | Domestic | 3100-3300 yuan / kg | 3200 | 0 |

| Yttrium | Y / TREM 99.9-99.95% | Domestic | 270-290 yuan / kg | 280 | 0 |

| Lanthanum Cerium metal | Ce / TREM ≥ 65.0% TREM ≥ 98.5% | Domestic | 46000-48000 yuan / ton | 47000 | 0 |

| Praseodymium neodymium metal | Pr / TREM 20-25% Nd / TREM 75-80% TREM ≥ 98.5% | Domestic | 435000-445000 yuan / ton | 440000 | 0 |

| Praseodymium Neodymium Dysprosium metal | TREM ≥ 99.0% | Domestic | 450000-470000 yuan / ton | 460000 | 0 |

| Battery grade mixed rare earth | TREM ≥ 99.0% Nd / TREM ≥ 15% | Domestic | 135000-145000 yuan / ton | 140000 | 0 |

| Dy alloy | Dy80% | Domestic | 2050000-2150000 yuan / ton | 2100000 | 0 |

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Multiple Composite Rare Earth Tungsten Electrodes Swaging String Playing Equipment Technology Device Model and its Parameters

- Details

- Category: Rare Earth News

- Published on Wednesday, 16 October 2013 16:46

- Hits: 1721

Multiple composite rare earth tungsten electrodes swaging process string playing devices invented by two of  the same model is used , the same frequency and speed of rotary forging machine (B201-B201, B202- B202) consisting of string playing devices multiple composite rare earth tungsten electrode material B202, B201 stage processing , B203, B202, B201 as tungsten and molybdenum in the regular machining processes , typically used for segmentation swaging process , is the use of B-203, B-202, B-201 swaging the swaging machine for processing . B-203, B-202, B-201 rotary forging machine for the device model , B-203 rotary forging machine rotary hammer stroke max , suitable for processing large workpieces ; B-202 rotary forging machine rotary hammer stroke , followed by appropriate machining small parts ; B-203 rotary forging machine rotary hammer stroke minimum , generally used for processing smaller parts. Die change system Φ6 other means swaging touched minimum diameter of 6mm.

the same model is used , the same frequency and speed of rotary forging machine (B201-B201, B202- B202) consisting of string playing devices multiple composite rare earth tungsten electrode material B202, B201 stage processing , B203, B202, B201 as tungsten and molybdenum in the regular machining processes , typically used for segmentation swaging process , is the use of B-203, B-202, B-201 swaging the swaging machine for processing . B-203, B-202, B-201 rotary forging machine for the device model , B-203 rotary forging machine rotary hammer stroke max , suitable for processing large workpieces ; B-202 rotary forging machine rotary hammer stroke , followed by appropriate machining small parts ; B-203 rotary forging machine rotary hammer stroke minimum , generally used for processing smaller parts. Die change system Φ6 other means swaging touched minimum diameter of 6mm.

Multiple composite rare earth tungsten electrodes swaging process parameters string playing devices formulation is based on multiple composite rare earth tungsten electrode materials developed organizational variation , the process of deformation of the electrode material organizational changes, recovery temperature and the recrystallization temperature is also based on the degree of deformation change so as to avoid multiple composite rare earth tungsten electrode material embrittlement recrystallization , also need to change the processing temperature to keep the temperature in the reply above the recrystallization temperature. Therefore, the equipment and technology to match the technical parameters , and is limited to multi-composite production and processing of rare earth tungsten electrodes , the main advantages of this process are: ( 1 )A process through two rotary forging dies , the original B202 6 step process reduced to three , the B201 process in four steps to reduce the current two , the processing efficiency doubled. ( 2 )Use of string playing techniques , billet machine after the first one rotary hammer forged quickly after entering the next rotary hammer forging machine , to avoid heat loss , and thus economic energy .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com