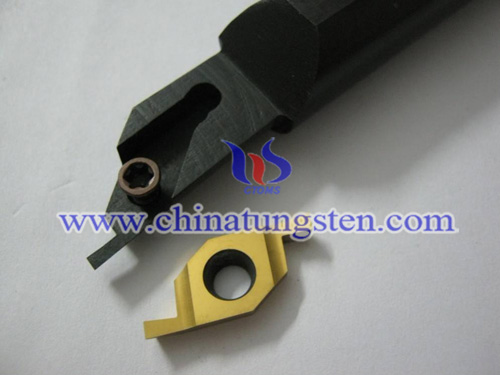

Tungsten Carbide Groove Cutter

- Details

- Category: Tungsten Information

- Published on Friday, 24 March 2017 16:39

Tungsten carbide groove cutter has high cutting accuracy and longer service life, which often used in manufacturing run-out groove in bearing parts, over-run of grinding wheel, snap ring groove and sealing groove and bore groove.

Types

There are many types of cutting groove, such as run-out groove in bearing parts, over-run of grinding wheel, snap ring groove and sealing groove and bore groove and so on. Lathe grooving cut divided into the outer tank, inner hole and the end face grooving. The tool can be used to cut the outer groove of turning face groove. Cut the outer groove and the end slot are rectangular arbor, and cut the groove commonly round or square arbor. In addition, the combined size of the blade and arbor must be less than the hole diameter to ensure the accuracy and improve the efficiency.

Characteristic

1. Small feed rate, even cutting thickness, large unit cutting force, better heat dissipation performance;

2. High cutting speed and uniform distribution;

3. The workpiece rotating and the tool cut continuously and form Archimedes screw surface;

4. Narrow edge width, suspended elongation, so it easily to vibrate when cutting or grooving.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com