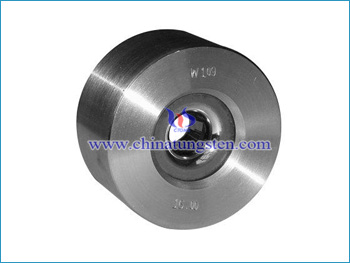

Tungsten Carbide Casting Die

- Details

- Category: Tungsten Information

- Published on Friday, 24 March 2017 16:36

Tungsten carbide casting die has better performance in heat resistance and fatigue resistance, which make casting component obtain good structure and mechanical properties by the extrusion of the molds. There are many types of tungsten carbide casting die mainly based on the manufacturing equipment, such as tire mold, hammer forging die, mechanical forging die, upset forging die and roll forging die, etc.

Tire mold: Used in free forging, is suitable for small forging parts and small batch production;

Hammer forging die: Under dynamic action of forging equipment, the blank forced plastic flow forming die in the die bore, resulting in higher quality than free forging;

Mechanical forging die: Mechanical presses for the forging blank or semi-finished molding;

Upset forging die: In the horizontal forging machine forging the blank is formed into a mold or semi-finished products.

Compared with casting process, metal after forging can improve its organizational structure and mechanical properties. Since the deformation of the metal and recrystallization, the original coarse dendrite and columnar grains become finer grain, recrystallized structure of uniform size. In addition, to ensure the continuity of the metal forging fibrous tissue, fibrous tissue and make forging shape consistent metal flow lines intact, to ensure parts with good mechanical properties and long service life with precision forging; cold extrusion, warm extrusion process to produce forgings, castings are unmatched by forging metal was pressured by the shape or suitable plastic deformation of the compression force required to shape objects.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com