Cerium Tungsten Oxide Catalyst Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 August 2019 22:43

Nitrogen oxides (NO, mainly NO and NO2) are important atmospheric pollutants, which can directly harm human health, especially the respiratory system, and can cause acid rain, photochemical smog and haze and other important environmental problems. NH3 selective catalytic reduction is a technology widely used in fixed source flue gas denitrification represented by coal-fired power plants and mobile source NOx emission control represented by diesel vehicles.

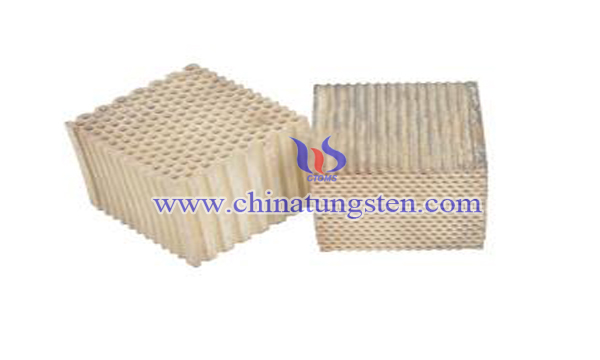

At present, the amount of medium and heavy rare earth is increasing all over the world, and the large backlog of high abundance of light rare earth elements such as cerium has become a difficult problem. It is very important to exploit the utilization ways of Ce for efficient and rational utilization of rare earth resources. SCR catalysts made of cerium and tungsten are likely to replace traditional catalysts. The preparation process includes:

(1)The mixed solid of cerium source and tungstate is prepared. The cerium source is selected from at least one of cerium nitrate, ammonium cerium nitrate, cerous chloride or cerium sulfate. Tungstates are selected from at least one of ammonium tungstate or ammonium paratungstate. The molar ratio of cerium source to tungstate is 0.5-2.0. The mixed grinding time is 0.5-1 h when grinding at room temperature.

(2)The cerium tungsten oxide catalyst is obtained by calcining the solid directly at 400-800 C for 4-6 H.

The preparation method of cerium tungsten oxide catalyst is extremely simple, less operation steps, short duration, low cost and environmental protection. It has very good anti-poisoning ability and thermal stability. It can still exhibit excellent catalytic performance at high space velocity. It is a very efficient SCR catalyst and is expected to replace the traditional catalyst.

sales@chinatungsten.com

sales@chinatungsten.com