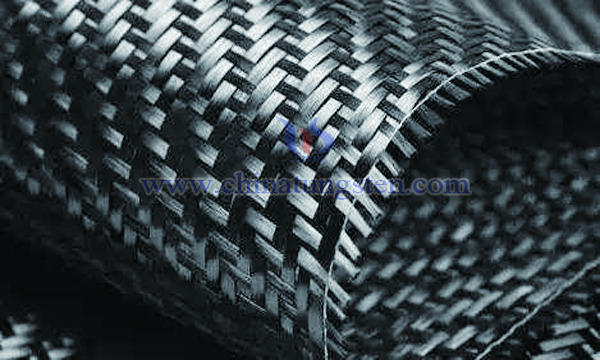

Carbon Fiber Tungsten Disulfide Nanosheet Core-Shell Composites

- Details

- Category: Tungsten Information

- Published on Sunday, 25 August 2019 15:14

Tungsten disulfide is a typical layered compound with graphene-like structure. The atoms in the layers are bound by strong covalent bonds, and the van der Waals force between layers is weak. Tungsten disulfide has special mechanical, optical and electrical properties due to its unique structure. Therefore, tungsten disulfide nanomaterials are not only widely used in lubrication and wear fields, but also in catalysis (such as visible light degradation of organic pollutants, visible light hydrogen production, electrocatalytic hydrogen production), lithium batteries (such as anode materials), photoelectric conversion (such as light emitting diodes, solar cells) and other fields. A wide range of attention has been paid by scientific researchers.

When tungsten disulfide and carbon materials are compounded, the core-shell composite structure can be adopted. By utilizing the pyrolysis of preoxidized polyacrylonitrile fibers to carbon at high temperature, the sulfur powder is directly evaporated by thermal evaporation technology in a vacuum tubular furnace. Under the action of carrier gas, the WO3 suspension is fumigated and soaked at high temperature. The pre-oxidized polyacrylonitrile fiber realizes the simultaneous synthesis of carbon fibers and tungsten disulfide nanosheets, and the core-shell composite material of carbon fibers tungsten disulfide nanosheets can be prepared in high yield. The following steps can be adopted:

(1)In a vacuum tube furnace, the alumina ceramic crucible with sulphur powder is placed 10-40 cm above the air flow from the central heating area of the furnace, and the quartz substrate containing pre-oxidized polyacrylonitrile fibers soaked in WO3 suspension is placed in the central heating area of the furnace.

(2)Before heating, vacuum pump is used to vacuum the whole system below 0.02Pa, then high purity inert carrier gas is injected into the system, and repeated many times to remove the air in the system. Then the temperature rises to 300-500 ℃ at the rate of 10-20 ℃/min and lasts for 5-20 minutes. Then it rises to 800-1100 ℃ at the rate of 10-30 ℃/min and lasts for 1-5 hours. In the heating process, under the premise of the continuous work of the vacuum system, the carrier gas flow is maintained at 100-300 standard cubic centimeters per minute, and the whole heating process is completed under the protection of inert carrier gas. Finally, when the temperature is naturally lowered to room temperature, a large number of high purity and high density carbon fibers-tungsten disulfide nanoparticles can be obtained on the substrate. Sheet-core-shell composite structure.

The carbon fiber tungsten disulfide nanosheet core-shell composite material has the advantages of simple equipment and process, strict and controllable synthetic growth conditions, high product yield, low cost, clean production process and environmental protection. The obtained core-shell composite structure has high density, high purity, ordered nano-scale, uniform diameter and thickness, controllable morphology and no post-processing.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com