Hexagonal Tungsten Oxide Preparation by Solid Phase Method

- Details

- Category: Tungsten Information

- Published on Thursday, 08 November 2018 22:05

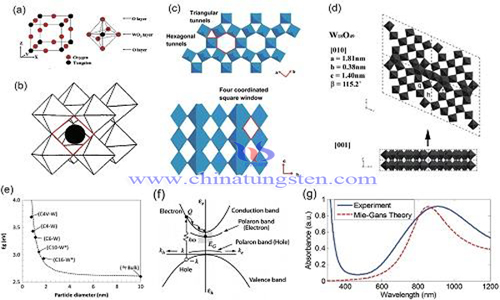

The hexagonal tungsten oxide has attracted much attention because its single crystal has an empty hexagonal space tunnel structure. W in the compound exists in the mixed valence states of W6+, W5+ and W4+, thus making the charge balance of the compound as a whole. This unique spatial structure and special valence state make it have good optical effect.

At present, mesostatic oxide nanomaterials are usually prepared by hydrothermal synthesis at medium and low temperatures. However, the synthesis conditions for preparing hexagonal tungsten oxide ultrafine powders by this method have some limitations. The hydrothermal conditions such as reaction temperature and pressure of the system have a close relationship with the structure and particles of the products. The interaction between them shows that hydrothermal synthesis of hexagonal tungsten oxide has complex factors and the reaction process is difficult to control.

A method for preparing hexagonal tungsten oxide spheres has been proposed, which is characterized by using glucose and ammonium metatungstate as raw materials, using programmed heating, sintering, heat preservation and natural cooling in a tubular furnace under inert atmosphere to obtain hexagonal tungsten oxide spheres. The main process is as follows:

Ammonium metatungstate was chosen as tungsten source, glucose as ball base, and the raw materials were weighed at the mass ratio of 1:2. Ammonium metatungstate 5.023g and 10.046g glucose were ground in a ball mill to an average particle size of 20 nm, so that the raw materials could be mixed evenly. The raw materials with uniform grinding and mixing were poured into a quartz boat, placed in the middle of the tube furnace, and put in the through. The powder of hexagonal tungsten oxide was obtained by sintering under the protection of argon gas, heating up to 900oC for 6 hours and cooling naturally after 6 hours of heat preservation.

The solid-phase preparation of hexagonal tungsten oxide is simple, with short period, easy operation of equipment, strong controllability, low energy consumption and complete one-time sintering. The reaction of raw materials at high temperature is very sufficient. The sphere size of the hexagonal tungsten oxide sphere obtained is 40-80 micron. There is no agglomeration between the spheres. Tungsten oxide nanorods have the same size. The rules adhere to the surface of the sphere with a length of 1 m to 5 m, which is conducive to industrial production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com