Analyzing Blue Tungsten Oxide Appearance

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 17:30

Learning blue tungsten oxide (BTO) phase morphology, size and uniformity, help to improve the performance blue tungsten oxide, so that it can be applied in more areas. To produce blue tungsten oxide is boat loading ammonium paratungstate (APT) to the hot zone and during the process to control the hydrogen flow, temperature and holding time these three parameters to produced blue tungsten oxide.

By using hydrogen reduction method to produce blue tungsten oxide and the surface of it has a large number of cracks and voids star, breakage obviously, it has lost the characteristics of hexagonal grains, forming a loose rule like appearance. Blue tungsten oxide surface has cracks is due to a large amount of water molecules and ammonium molecules which is produced from APT decomposition during the reaction. So the crystal inside of APT will cause inner stress to make crystal lattice mutation, resulting in cracks. At the same time, the external hydrogen to penetrate APT inside promoted deepening and expanding of cracks. Because of this crack APT generating vacancies and in baking time it caused partial intense contractions to make further fragmentation then to produce a fine particle powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Grain Size

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 12:16

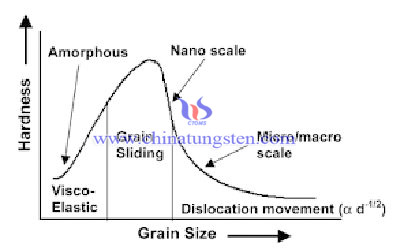

It is known that tungsten carbide hardness and toughness is affected by the WC grain size. For the finer grain size could be adopted in tungsten carbide cutting tools for light to medium-heavy roughing cuts, whereas the much tougher carbides- the coarse grain size over 8 μm, instead of cutting, they are applied in forming dies. In terms of medium grain size leads to a balance between hardness and toughness and are likely to be used for heavier rough cutting. Specially, if the grain size varies from 0.5μm to 1μm, it falls into micrograin carbides, with which the tungsten carbide cutting tools could offer more wear resistance, sharper cutting edge and better surface finish for hardened steels machining.

With nowadays cutting-edge technology, a hard tungsten carbide adopts using “ultrafine” WCpowder with less than 1% Co binder could offer moderate fracture toughness.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Anti-Scatter X-Ray Collimators

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 09:56

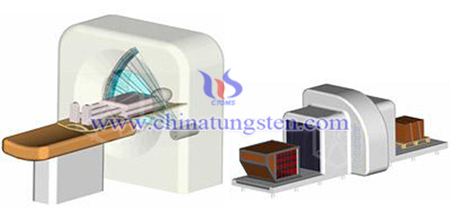

Tungsten anti-scatter collimators (also referred to as anti-scatter septa or grid), which is comprised by tungsten shielding, are used in CT X-ray equipment used for medical imaging, but also non-medical X-ray applications such as cargo scanners at (air)ports.

CT scanners consist of an x-ray source opposite an arc-shaped array of detectors. The collimator is located immediately in front of the detectors to protect them from scattered X-rays. Ideally, each detector in a CT scanner measures intensity of X-rays that reach the detector after traveling along a straight-line path from the X-ray source to the detector.

The commonly known tungsten anti-scatter collimator is comprised of thin plates formed from tungsten shieldling, which is suitable X-ray absorbing material. These tungsten plates are focused at the x-ray focal spot and generally located between columns of detectors (z-direction) but not between rows of detectors. This collimator is referred to as a "1D" anti-scatter collimator. In multi-slice scanners it has been found more advantageous to have shielding between both columns and rows of detectors; both directions are focusing to the X-ray source. This type is called a "2D" anti-scatter collimator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Features of Tungsten Alloy Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2015 09:54

Tungsten heavy alloy is a composite metal alloy with up to 97% tungsten and 3% binding agents. Tungsten alloy often appears as a shield against x-ray and gamma-ray. It is also used for radiation shielding or as a collimator to focus radiation beams onto a target. In fact, these shields work so well that they have been used for many years by engineers that require radiation shielding or collimators. This is because tungsten alloy shielding has very high density,virtually 60% denser than lead. Hence, it provides superior attenuation characteristics for x-ray and gamma radiations.

There are many features of tungsten material is a preferred choice for radiation shielding. Here are some of the main features:

Tungsten has high effective in blocking harmful X-ray and gamma radiation.

Tungsten is nontoxic.

Tungsten is thinner and even lighter than lead shields.

Tungsten is not only easy to sterilize but is also easy to clean.

It is dimensionally stable up to 1000C.

Tungsten is hard, durable and easily machined with conventional tools.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Small Size Violet Tungsten Oxide Particle Influence Factors (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 18:21

After the study found that factors which affecting the violet tungsten oxide particle sizes have material (APT) particle size and production process conditions. Production process conditions include reducing temperature, heating rate, water vapor and hydrogen pressure ratio, material thickness and reaction time.

Firstly, the influence factor is water vapor and hydrogen partial pressure ratio, which are water vapor and hydrogen partial pressure ratio increases and the size of products larger. This is mainly due to the formation of hydrogen gas to form a volatile humidity hydrous tungsten oxide, tungsten oxide which is easy to cover the finer particles, so that the particle size increases. Second, the impact factor is heating rate, after experiment found that to produce fine particles the heating speed should not too fast. When the reduction in a tube furnace, the heating rate depends on the furnace temperature gradient and push the boat speed, hence reducing the furnace temperature gradient and push the boat speed are conducive to obtain fine particles of violet tungsten oxide. Thirdly, the reduction temperature influence violet tungsten oxide particle size. When the temperature increase the particle is grouping up. At the same time the reducing time also impacts on violet tungsten particles, the greater the reduction reaction of the longer particle size. Finally, the thickness of the material layer, the material thickness is larger, the larger the particle size of the product.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Small Size Violet Tungsten Oxide Particle Influence Factors(1)

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 18:20

With the development of research, the ultra-fine particles as a new material have been widely used in modern industry and science. Violet tungsten oxide (VTO) has special properties and structure so get a lot of favor in the producing ultrafine tungsten powder. During producing tungsten powder not only process conditions is important but the raw marital particle size is also an important factors. Therefore, to study the factors which influence violet tungsten particle size is very important.

Producing violet tungsten oxide is through boatload an amount of ammonium paratungstate and pushes it into the reduction furnace hot zone. At the same time add a certain proportion of hydrogen and steam mixture to heat at a certain temperature, after a period heat preserving then cooling to obtain.

During the reaction, the factors that influence the violet tungsten oxide grain size are the raw material (APT) particle size and production process conditions. Production process conditions include reducing temperature, heating rate, water vapor and hydrogen pressure ratio, material thickness and reaction time. The study showed that, the relationship between violet tungsten oxide and raw material particle size is raw materials get smaller the particle size is smaller.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Violet Tungsten Oxide Main Phase Of Reduction Reaction

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 18:18

Understanding the main phase of violet tungsten oxide (VTO) has great impact on producing good properties tungsten powder. Because violet tungsten oxide main phase will influence tungsten particle grains morphology. Violet tungsten oxide in hydrogen reduction process undergone two major phase transition, γ-tungsten oxide→tungsten oxide (WO2.72) → tungsten dioxide (WO2) → tungsten powder.

After study found during the restore reaction the first phase transition is violet tungsten oxide to tungsten dioxide. At this stage with the reduction development the oxygen atoms decrease and oxygen vacancy increase of violet tungsten oxide, tungsten dioxide particles become denser than γ- tungsten oxide. But this is not easy to make hydrogen gas into the interior of the particles, the reduction process of the water molecules are also difficult to discharge, which is not conducive to the produce ultrafine or nano tungsten powder.

In the second stage of phase transition is tungsten dioxide restore to tungsten powder. According to the phase data, with the degree of reduction depth, tungsten dioxide’s oxygen atoms decrease and vacancies increased, resulting denser particles of tungsten powder, but little different with tungsten dioxide. Obviously, the morphology change of tungsten powder happen before produce tungsten dioxide.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analyzing the Submicron Tungsten Oxide‘s Morphology Producing By Violet Tungsten Oxide (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 18:16

After many observed violet tungsten oxide the researchers found violet tungsten oxide has special structure which is good for producing fine or submicron tungsten powder.

After detailed studies of these three powders found loose structure violet tungsten oxide is conducive to speed up the reaction proceeds, and powder particle size is small than using other tungsten oxide to produce.

Using violet tungsten oxide as raw material to produce tungsten powder and the tungsten powder particle shape is kind of short rod or a chain particles which form by many particles, uniform size, particle size between 0.1 ~ 1um. Tungsten carbide powder particles shape is mainly equiaxed particle, uniform size, particle size is also between 0.1 ~ 1um. But the size is larger than the tungsten powder. This is mainly due to when carbonization the tungsten atoms does not occur large migration.

So using violet tungsten oxide to produce submicron tungsten oxide and tungsten carbide powder the particle shape are complicate and also has little single particle exist.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analyzing the Submicron Tungsten Oxide‘s Morphology Producing By Violet Tungsten Oxide (1)

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 18:14

Violet tungsten oxide (VTO) has a special structure and properties, is one of the most suitable materials for producing fine tungsten powder. Using violet tungsten as raw material by hydrogen reduction to obtain tungsten powder, tungsten powder and carbon mixture obtained submicron tungsten carbide powder, and then mixed with carbide powder to form submicron tungsten powder which has great significance for producing outstanding performance superfine alloy. Through the study of tungsten powder and tungsten carbide powder properties so that they can be more widely used in the different fields.

Through data analysis, violet tungsten oxide has special structure which is different form other tungsten oxide. Violet tungsten oxide is combined with rod-like and needle-like crystal, there are non-uniform of thickness, but it has big length-diameter ratio. So the kind of this structure has a lower bulk density which is good for hydrogen reduction reaction. So that the tungsten powder and tungsten carbide powder which produce by violet tungsten oxide can obtain submicron level particle size.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Using Activated Tungsten Oxide to Produce Tungsten Powder (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2015 18:13

After many researches, the researchers found activated tungsten oxide is good for producing fine tungsten oxide than blue tungsten oxide. So compare the different between blue tungsten oxide and blue tungsten oxide.

The maximum content of the impurity element of activated tungsten oxide is similar with blue tungsten oxide. The mine phase of activated tungsten oxide phase is bronze (ATB) and the main phase of blue tungsten oxide is WO2.9. The physical properties of activated tungsten oxide are: bulk density of it is 2.3 ~ 2.8g • cm-1, -100 mesh sieve, specific surface area bigger than 3cm 2 • cm-3. Blue tungsten oxide physical properties is small different with activated tungsten oxide.

The study showed that in the same process, using activated tungsten oxide to produce tungsten powder there are little coarse crystalline grain and particle-piled which compare to blue tungsten oxide, besides tungsten powder are more uniformity and concentrated. So using activated tungsten oxide to produce tungsten powder is finer than using blue tungsten oxide.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com